Preparation process of amantadine hydrochloride

A technology of amantadine hydrochloride and preparation process, applied in the field of preparation technology of amantadine hydrochloride, can solve the problem that amantadine has no resistance to influenza B virus and parainfluenza virus, etc., so as to improve product purity and improve product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

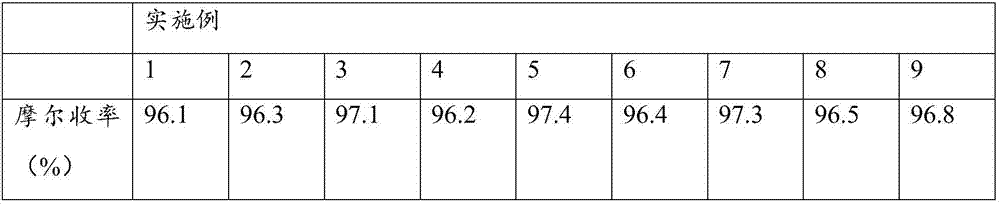

Examples

Embodiment 1

[0044] Preparation process of amantadine hydrochloride

[0045] (1) Add 400mL of 25% oleum to a 1000mL three-necked reaction flask, stir and cool to 10°C, add 100g of adamantane, control the temperature in the reaction flask at 10°C, and slowly add dropwise at a rate of 0.1mL / s After dropping 80 mL of acetonitrile, the temperature of the solution in the reaction flask was raised to 15°C for 2h, then to 25°C for 2h, and finally to 32°C for 1h, the reaction was completed.

[0046] (2) Add 2000 mL of water to another 3000 mL three-necked reaction flask, stir and cool down to 5°C, slowly add the reaction solution of step (1) at a rate of 2 mL / s, and control the dropping temperature at about 5°C. After finishing, control the temperature of the solution to keep at about 5°C, while stirring for 0.5h, filter, and drain to obtain 1-acetamide fundmantane.

[0047] (3) Add 800 mL of 30% industrial hydrochloric acid to a 1000 mL three-necked reaction flask, and then add the 1-acetamide methaned...

Embodiment 2

[0049] The main difference from Example 1 lies in the difference in the process of raising the temperature in the first step, which is specifically as follows.

[0050] (1) Add 400mL of 25% oleum to a 1000mL three-necked reaction flask, stir and cool to 10°C, add 100g of adamantane, control the temperature in the reaction flask at 10°C, and slowly add dropwise at a rate of 0.1mL / s After dropping 80 mL of acetonitrile, the temperature of the solution in the reaction flask was raised to 20°C for 1 hour, then to 30°C for 1 hour, and finally to 35°C for 2 hours. The reaction was completed.

[0051] (2) Add 2000 mL of water to another 3000 mL three-necked reaction flask, stir and cool down to 5°C, slowly add the reaction solution of step (1) at a rate of 2 mL / s, and control the dropping temperature at about 5°C. After finishing, control the temperature of the solution to keep at about 5°C, while stirring for 0.5h, filter, and drain to obtain 1-acetamide fundmantane.

[0052] (3) Add 800 ...

Embodiment 3

[0054] The main difference from Example 1 lies in the difference in the process of raising the temperature in the first step, which is specifically as follows.

[0055] (1) Add 400mL of 25% oleum to a 1000mL three-necked reaction flask, stir and cool to 10°C, add 100g of adamantane, control the temperature in the reaction flask at 10°C, and slowly add dropwise at a rate of 0.1mL / s After dropping 80 mL of acetonitrile, the temperature of the solution in the reaction flask was increased to 18°C for 1.5h, then to 30°C for 1h, and finally to 35°C for 1.5h, and the reaction was completed.

[0056] (2) Add 2000 mL of water to another 3000 mL three-necked reaction flask, stir and cool down to 5°C, slowly add the reaction solution of step (1) at a rate of 2 mL / s, and control the dropping temperature at about 5°C. After finishing, control the temperature of the solution to keep at about 5°C, while stirring for 0.5h, filter, and drain to obtain 1-acetamide fundmantane.

[0057] (3) Add 800 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com