Pr-MOFs (praseodymium-metal organic frameworks) crystal material as well as preparation method and application thereof

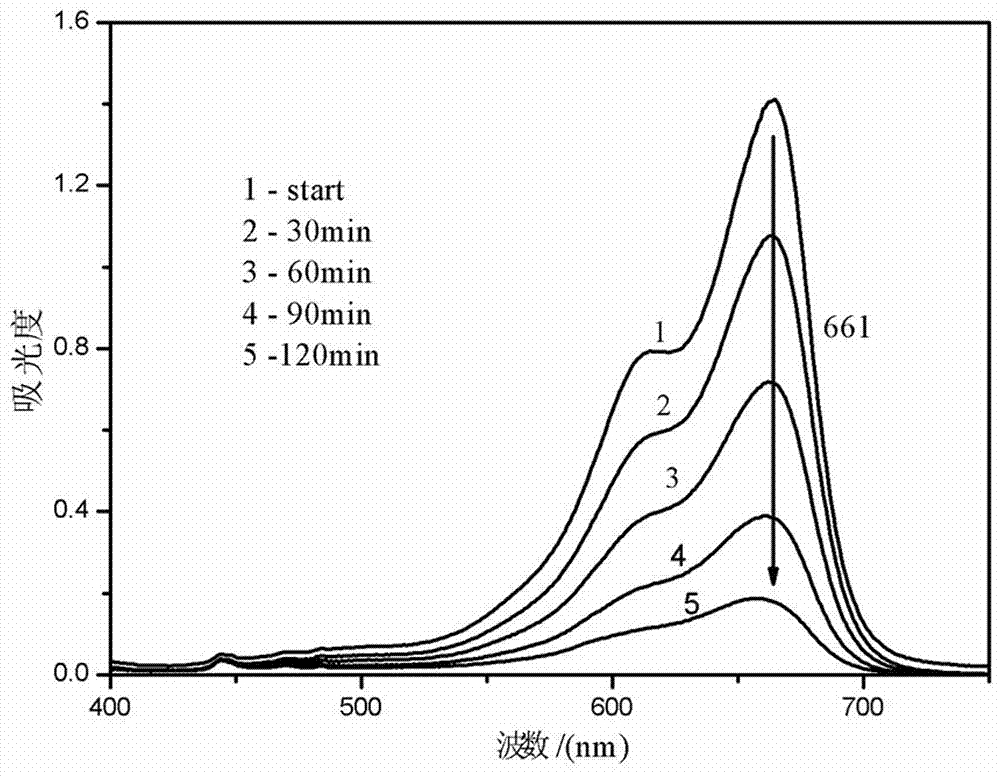

A technology of crystal material and reaction solution, applied in the field of photocatalysis, can solve problems such as low energy efficiency, and achieve the effects of high degradation rate, high yield and simple experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

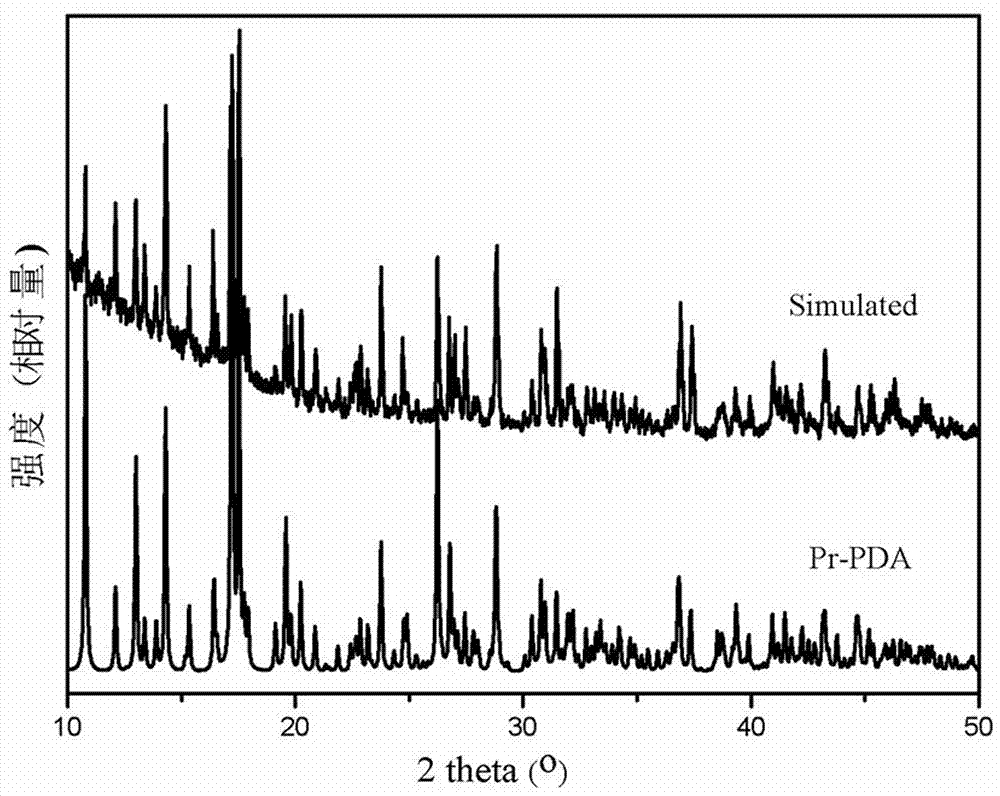

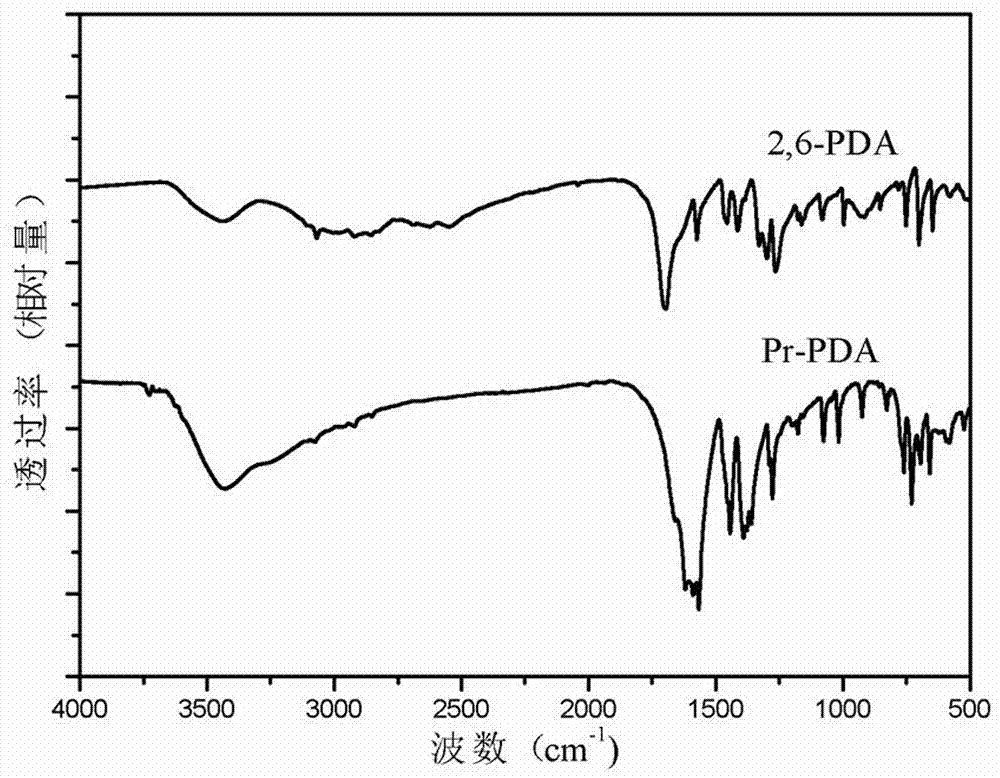

[0025] A preparation method of Pr-MOFs crystal material:

[0026] Step (1) Preparation of the reaction solution, weigh 435.01 mg of praseodymium nitrate hexahydrate and add 15 ml of distilled water with magnetic stirring to obtain a clear cobalt nitrate solution, then weigh 167.1 mg of 2,6-pyridinedicarboxylic acid and add 8 ml of absolute ethanol with magnetic stirring A clear 2,6-pyridinedicarboxylic acid solution was obtained, and then the above two solutions were mixed and ultrasonically treated in a water bath at 40 °C for 15 min to obtain a reaction solution.

[0027] Step (2) Preparation of Pr-MOFs crystal material, put the reaction solution in step (1) into the reactor and place it in an oven at 160 °C for 72 h. After the reaction, control the oven to cool down to room temperature at 5 °C / min, and let it stand After treatment for 2 days, the filtered product was washed three times with distilled water and absolute ethanol, and dried in an oven at 80 °C for 24 h to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com