Ink composition and preparation method thereof

A composition and ink technology, which is applied in the manufacturing and application of inks, semiconductor/solid-state devices, etc., can solve problems such as the description of hydroxyl-containing components, and achieve the effect of improving performance and saving ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

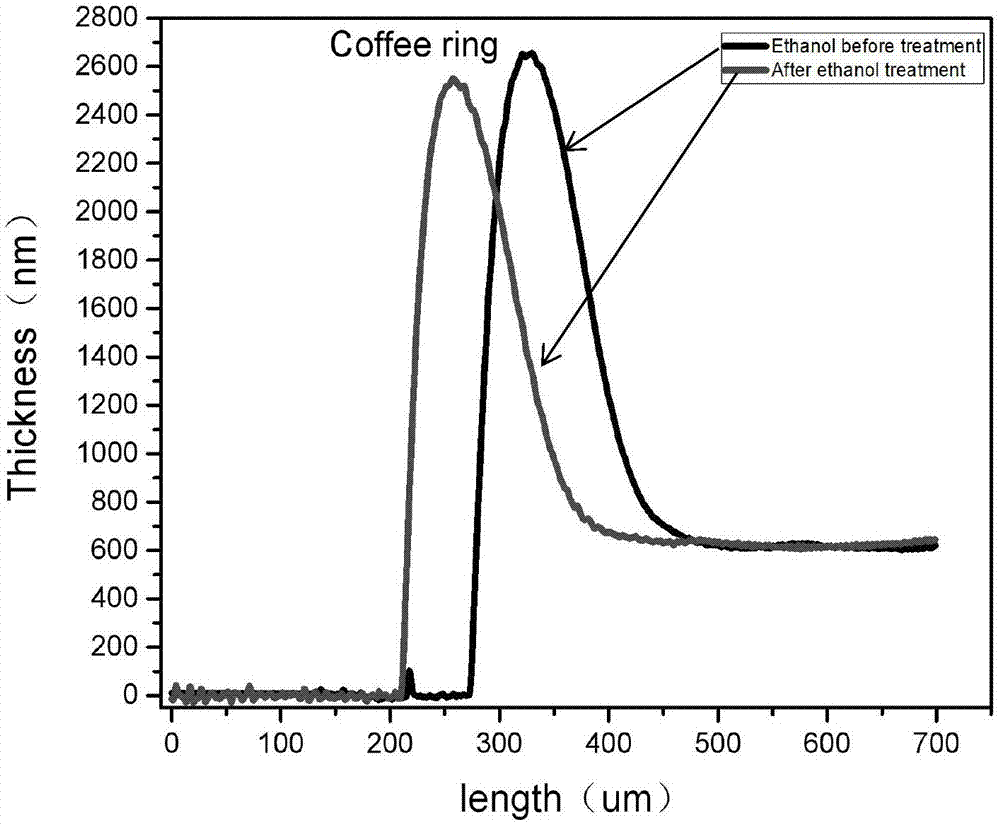

Image

Examples

Embodiment 1

[0036] A. Ink preparation

[0037] Take 0.1958g of 2,4,6-Triallyloxy-1,3,5-triazine (purchased from Sigma-Aldrich, model 291609), 0.2878g of pentaerythritol tetra-3-mercaptopropionate (purchased In Sigma-Aldrich, model 381462), 2.3mg of 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butanone (purchased from Sigma-Aldrich, model 405647), 50mg Surfactant Triton TM X-100 (purchased from Sigma-Aldrich, model 9002-93-1) in 1 mL of propylene glycol monomethyl ether acetate solution. Among them, 2,4,6-triallyloxy-1,3,5-triazine, pentaerythritol tetra-3-mercaptopropionate, 2-benzyl-2-dimethylamino-1-(4- The mass ratio of morpholinophenyl) butanone in the ink composition is 1:1.47:0.012.

[0038] After the ink composition is configured, it is stirred for 0.1-2h and ultrasonicated for 1-10min at an ultrasonic frequency of 20-40kHz, and then the ink composition is filtered with a disposable syringe filter with a precision of 0.1-0.5μm.

[0039] The standard principle of rheological measur...

Embodiment 2-12

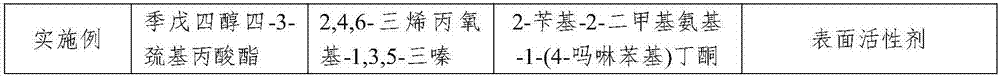

[0044] The preparation method of the ink composition and the preparation steps of the medium layer are the same as in Example 1, except for the components of the ink composition, which are specifically listed in Table 1.

[0045] Table 1 Ink composition component table

[0046]

[0047]

[0048] Table 2 Ink viscosity and surface tension

[0049] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com