Production method and application of silicon dioxide-modified porous urea-resin-based carbon spheres

A technology of silica and urea-formaldehyde resin, used in carbon preparation/purification, hybrid capacitor electrodes, etc., can solve problems such as poor thermal stability and achieve stable structure, weakened melt fluidity, and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dissolve 6.0g of urea in 150.0mL of distilled water under stirring conditions, add 13.0g of formaldehyde and 5.0mL of formic acid in sequence, react for 15min and then let it stand for 24h, then filter and wash the obtained reaction solution until neutral, Dry at 60°C for 12h, then impregnate the product in 2.0mol / L HCl aqueous solution at room temperature and stir for 24h to solidify, the mixture is suction filtered again, washed until neutral, and dried at 60°C for 12h to obtain porous urea-formaldehyde resin microstructure ball;

[0031] (2) The porous urea-formaldehyde resin microspheres obtained in step (1) were carbonized at 800°C for 3 hours under the protection of argon, cooled to room temperature naturally, and black powder was obtained after grinding, that is, urea-formaldehyde resin-based carbon material.

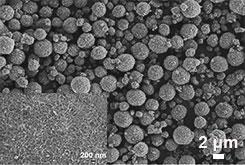

[0032] The scanning electron micrograph of the porous urea-formaldehyde resin microsphere that present embodiment makes is as figure 1 shown by figu...

Embodiment 2

[0035] (1) Put 0.5g of silicon dioxide in 150.0mL of distilled water and ultrasonically treat it, so that the silicon dioxide is evenly dispersed in the aqueous solution;

[0036] (2) Dissolve 6.0g of urea in the mixed solution obtained in step (1) under stirring conditions, add 13.0g of formaldehyde and 5.0mL of formic acid in sequence, react for 15min and then let it stand for 24h, then filter the obtained reaction solution, Wash until neutral, dry at 70°C for 13h, then immerse the product in 2.0mol / L HCl aqueous solution at room temperature, stir and solidify for 24h, the mixed solution is filtered again, washed until neutral, and dry at 70°C for 13h, Obtain urea-formaldehyde resin microspheres containing porous silica;

[0037] (3) The porous urea-formaldehyde resin microspheres containing silica obtained in step (2) were carbonized at 800°C for 3 hours under the protection of argon, and cooled naturally to room temperature;

[0038] (4) Place the product obtained in step...

Embodiment 3

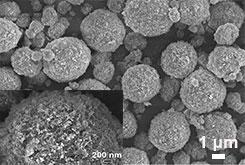

[0040](1) Put 1.0g of silicon dioxide in 150.0mL of distilled water and ultrasonically treat it, so that the silicon dioxide is evenly dispersed in the aqueous solution;

[0041] (2) Dissolve 6.0g of urea in the mixed solution obtained in step (1) under stirring conditions, add 13.0g of formaldehyde and 5.0mL of formic acid in sequence, react for 15min and then let it stand for 24h, then filter the obtained reaction solution with suction, Wash until neutral, dry at 70°C for 11h, then immerse the product in 2.0mol / L HCl aqueous solution at room temperature, stir and solidify for 24h, then filter the mixed solution again, wash to neutral, and dry at 70°C for 11h. Obtain porous urea-formaldehyde resin microspheres containing silicon dioxide;

[0042] (3) The porous urea-formaldehyde resin microspheres containing silica obtained in step (2) were carbonized at 800°C for 3 hours under the protection of argon, and cooled naturally to room temperature;

[0043] (4) Place the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com