One-component rod sticking glue and preparation method thereof

A sticky stick, one-component technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of high epoxy AB adhesive viscosity, affecting silicon wafer yield, and silicon wafer collapse To solve problems such as shortage, to achieve the effect of low viscosity, improved silicon wafer yield and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

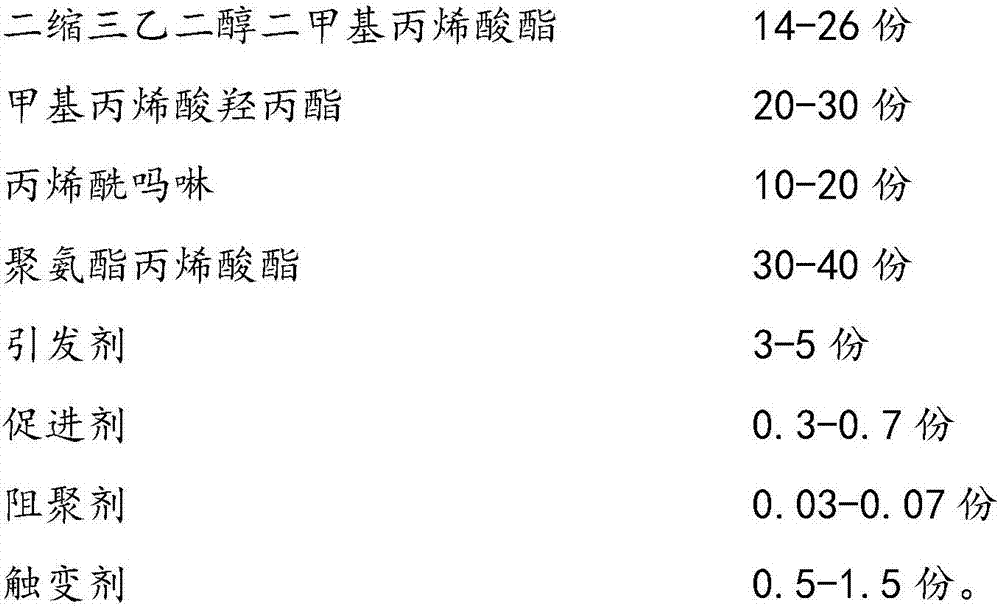

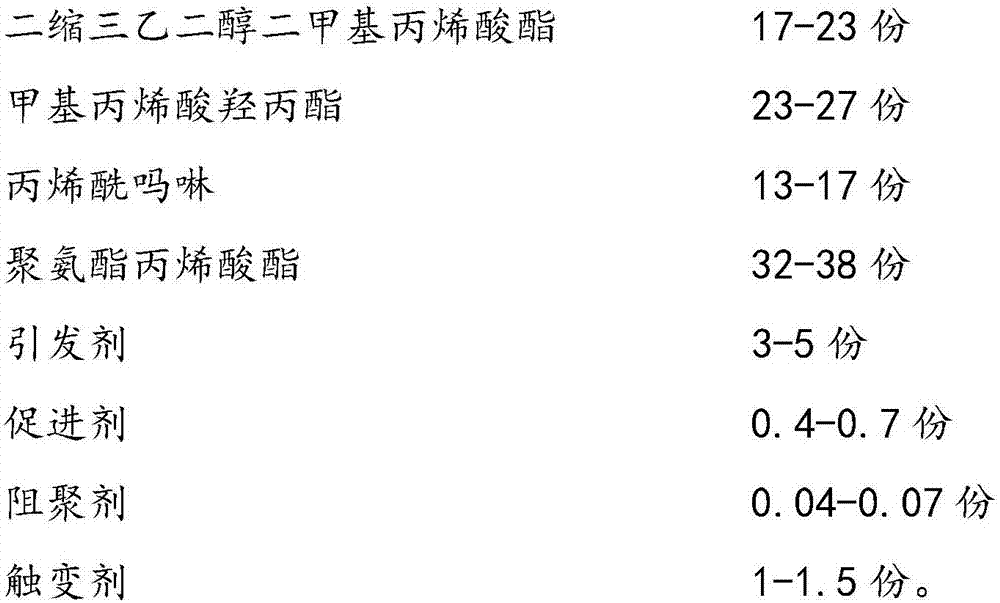

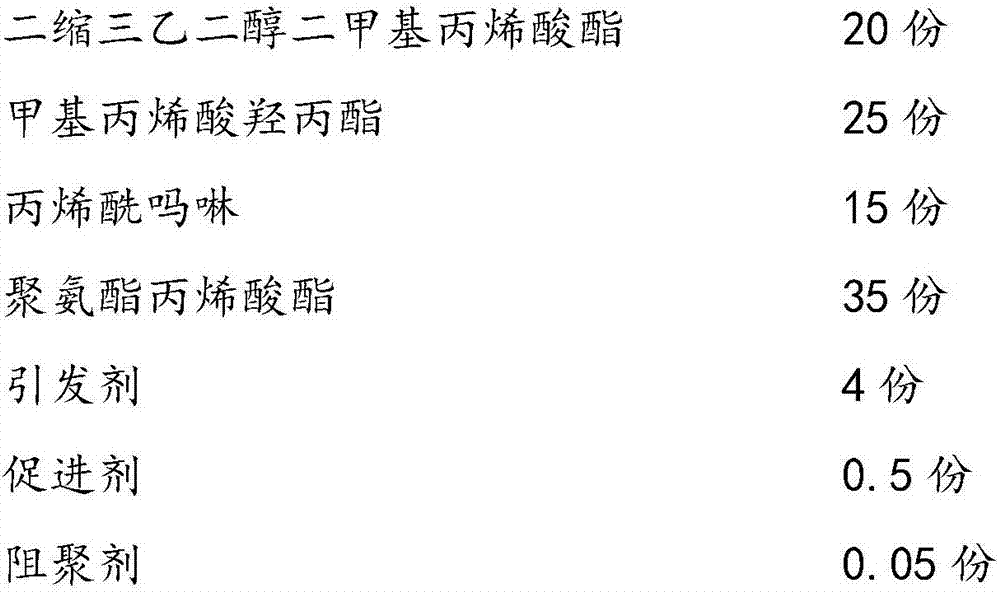

[0030] A kind of one-component stick glue of the present embodiment, by weight, comprises the following components:

[0031] 20 parts of triethylene glycol dimethacrylate, 25 parts of hydroxypropyl methacrylate, 15 parts of acryloyl morpholine, 35 parts of difunctional polyurethane acrylate, 4 parts of cumene hydroperoxide, 0.5 parts of saccharin part, 0.05 part of p-benzoquinone, and 1 part of fumed silica.

[0032] The preparation method of above-mentioned one-component sticky stick glue may further comprise the steps:

[0033] Step 1, weigh triethylene glycol dimethacrylate, hydroxypropyl methacrylate, acryloyl morpholine, difunctional urethane acrylate, saccharin, p-benzoquinone, and fumed silica in parts by weight In the reaction kettle, the temperature was raised to 40°C, and the reaction was stirred for 2 hours at a speed of 600r / min;

[0034] Step 2, after the reaction is completed, cool to room temperature, add cumene hydroperoxide, and continue stirring for 20 minu...

Embodiment 2

[0042] A kind of one-component stick glue of the present embodiment, by weight, comprises the following components:

[0043] 14 parts of triethylene glycol dimethacrylate, 30 parts of hydroxypropyl methacrylate, 20 parts of acryloyl morpholine, 31 parts of difunctional polyurethane acrylate, 4.5 parts of cumene hydroperoxide, 0.5 parts of saccharin parts, 0.05 parts of p-benzoquinone, and 0.5 parts of fumed silica.

[0044] The preparation method and construction process of the one-component stick glue in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0046] The single-component sticky glue of the present embodiment, by weight, includes the following components:

[0047] 26 parts of triethylene glycol dimethacrylate, 20 parts of hydroxypropyl methacrylate, 19 parts of acryloyl morpholine, 30 parts of difunctional polyurethane acrylate, 3.5 parts of tert-butyl hydroperoxide, sodium saccharin 0.7 parts, p-benzoquinone 0.07 parts, fumed silica 1.5 parts.

[0048] The preparation method of the present embodiment one-component sticky stick glue may further comprise the steps:

[0049] Step 1, weigh triethylene glycol dimethacrylate, hydroxypropyl methacrylate, acryloyl morpholine, difunctional urethane acrylate, sodium saccharin, p-benzoquinone, and fumed silica in parts by weight Add it into the reaction kettle, raise the temperature to 35°C, and stir for 2 hours at a speed of 700r / min;

[0050] Step 2, after the reaction is completed, cool to room temperature, add tert-butyl hydroperoxide, and continue stirring for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com