A Cementing-Formation Solidification Integrated Fluid Applied to Deep Water Weakly Consolidated Formation

A weakly cemented, formation technology, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem that the target interval cannot be fully solidified, and it is difficult to ensure the contact time between the solidified slurry and the formation, and the grouting pipe It is difficult to solve the problems of placement and recycling, and achieves high environmental protection and economic benefits, improved curing strength, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

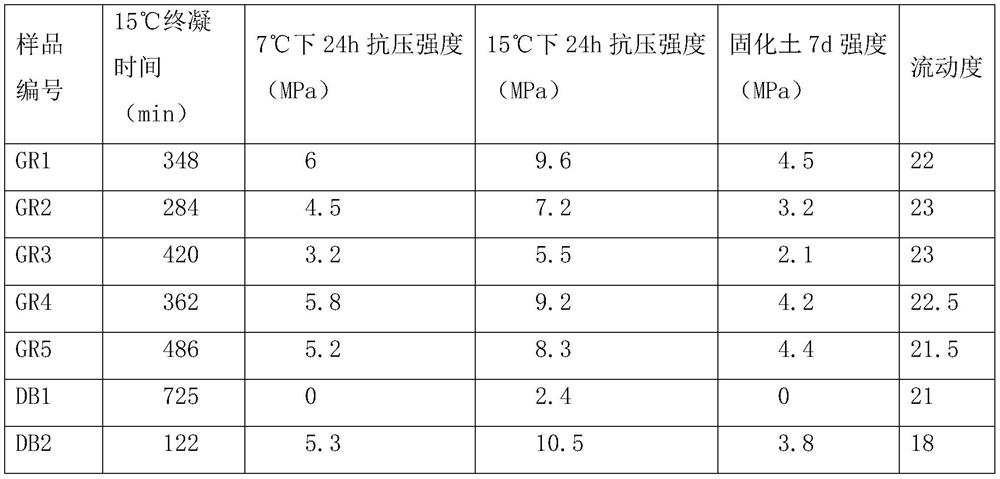

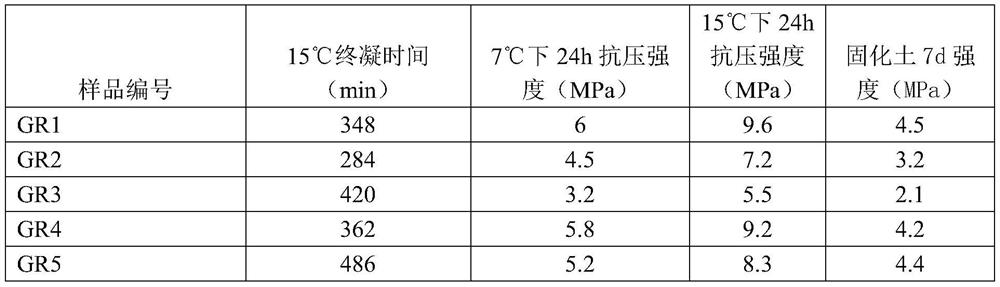

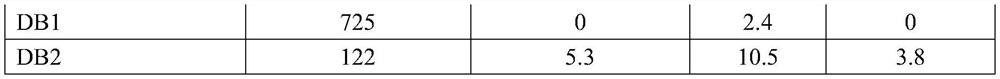

[0029] The mass ratio of each component of the cementing-solidification integrated fluid is:

[0030] 400g of ultrafine slag (1250 mesh), 320g of water, 24g of sodium hydroxide, 7.6g of epoxy resin, 12.4g of curing agent, 40g of hollow glass microspheres, 2.4g of silane coupling agent, denoted as GR1.

[0031] Stir and mix evenly to prepare the cementing-curing integrated fluid slurry specimen, measure the setting time at 15°C, and the compressive strength at 7°C and 24h curing at 15°C.

[0032] Weigh respectively 15% and 20% cementing-curing integrated fluid to prepare soft soil solidified samples, weigh 700g of prepared soil samples, mix and stir evenly to obtain solidified soil samples, measure at 7°C, 15°C Under curing for 7 days unconfined compressive strength.

Embodiment 2

[0034] The content of each component of the cementing-solidification integrated fluid is changed, and the others are the same as in Example 1. The mass ratio of the components of the cementing-solidification integrated fluid is: 400g of ultrafine slag (1250 mesh), 320g of water, and 24g of sodium hydroxide , epoxy resin 15.2g, curing agent 24.8g, 40g hollow glass microspheres, 2.4g silane coupling agent, denoted as GR2.

Embodiment 3

[0036] The content of each component of the cementing-solidification integrated fluid is changed, and the others are the same as in Example 1. The mass ratio of the components of the cementing-solidification integrated fluid is: 400g of ultrafine slag (1250 mesh), 360g of water, and 24g of sodium hydroxide , epoxy resin 7.6g, curing agent 12.4g, 40g hollow glass microspheres, 2.4g silane coupling agent, denoted as GR3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com