Visualization experiment system and device for testing separation characteristics of condensation water

An experimental system and characteristic testing technology, applied in measuring devices, testing of machine/structural components, material condensation, etc. It can solve the problem of large lens size, and achieve the effect of diverse functions, ensuring accuracy, and efficient synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

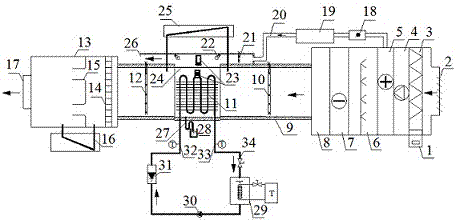

[0020] Attached below figure 1 and figure 2 Specific embodiments of the present invention will be described in detail.

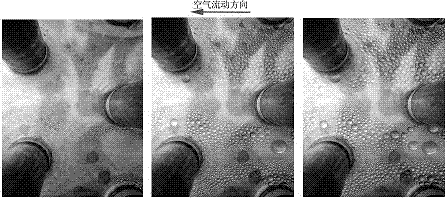

[0021] like figure 1 As shown, the visual experiment system and its device include a combined air conditioning system, a condensed water visual test unit, an air flow test unit and a chilled water system. The combined air conditioning system consists of an air inlet (2), a filter section (3), a variable frequency fan section (4), a heating section (5), a humidification section (6), a surface cooling section (7), and an equalizing section (8). and a combined air-conditioning system control box (1); the condensate visual test unit is composed of an insulating air duct (9), a dry and wet bulb thermometer I (10), a prototype test section (11), a dry and wet bulb thermometer II (12), Butterfly valve (18), solid moisture absorber (19), dry air duct (20), dry and wet bulb thermometer III (21), shadowless light source (22), endoscope (23), anti-fog transparent g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com