Splicing type installation method for flexible thin film solar cell module of curtain or roof photovoltaic power station

A technology of solar cells and solar modules, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of increased weight, damage to the roof waterproof layer, complicated installation process, etc., and achieves low cost, easy large-area installation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described through the following embodiments in conjunction with the accompanying drawings, but not limited to the content of this embodiment.

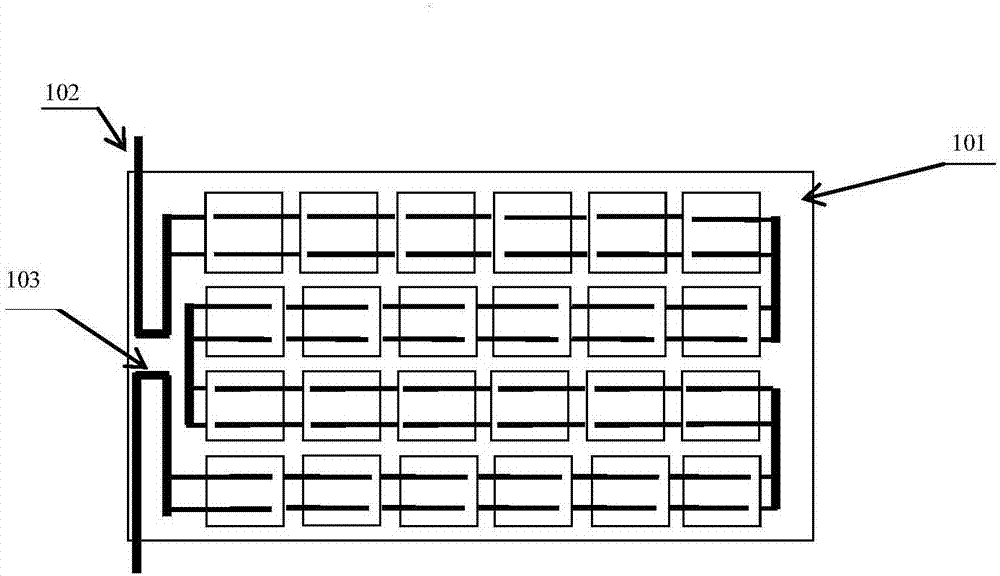

[0043] See attached figure 1 A method for adhesively installing flexible thin-film solar cell components of a curtain wall or roof photovoltaic power station comprises a flexible thin-film solar cell component 101 and an adhesive material.

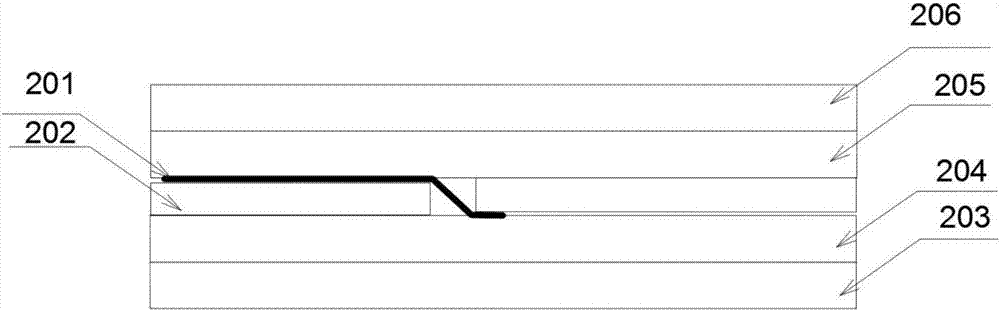

[0044] The flexible thin-film solar cell module 101 includes: a lower water-blocking film 203, a lower cross-linked film 204, a flexible thin-film solar cell chip 202, a conductive copper strip 201, an upper cross-linked film 205, a high-transmittance upper water-blocking film 206, Connector 102. Wherein, the upper water-blocking film can be a composite film, which itself can be composed of multiple layers with high water-blocking properties, or can be a single film layer.

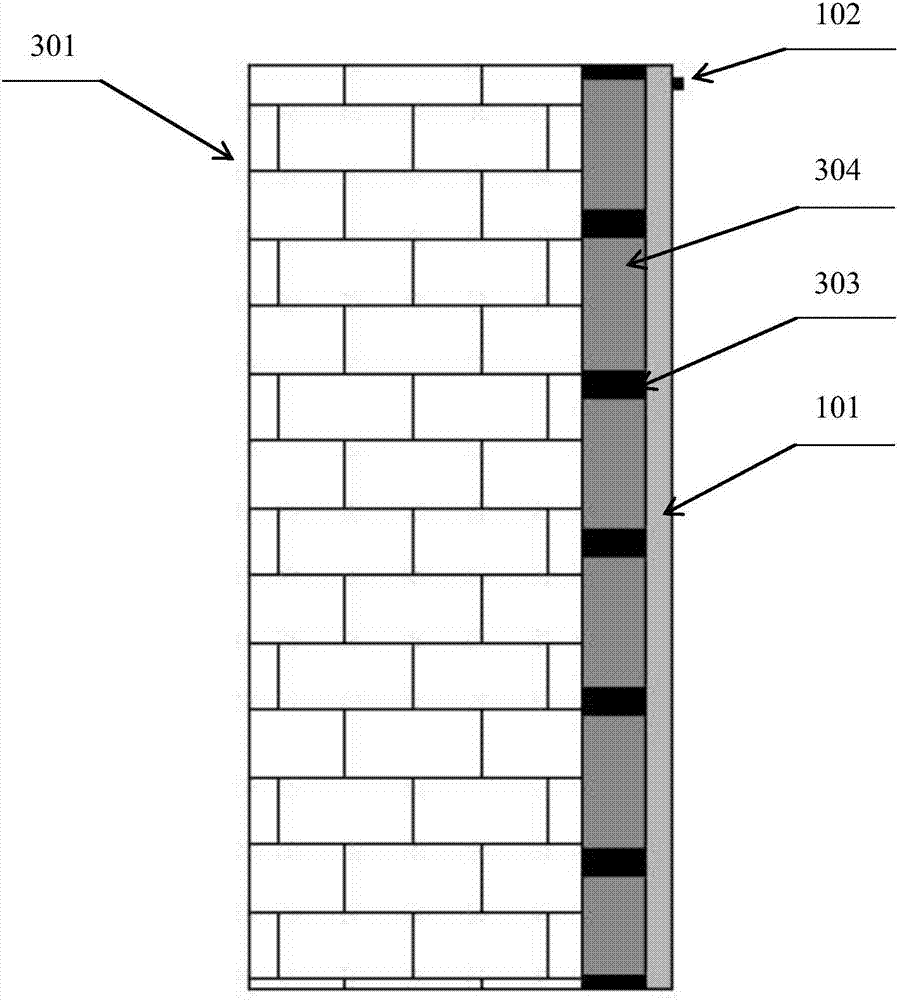

[0045] The adhesive material is double-sided tape 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com