Low-rank coal degradation solution flavor beverage

A degradable liquid, youthful technology, applied in sugary food ingredients, food ingredients as pH modifiers, food ingredients as taste modifiers, etc. Achieving pH reduction, increased safety, sourness, and heaviness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

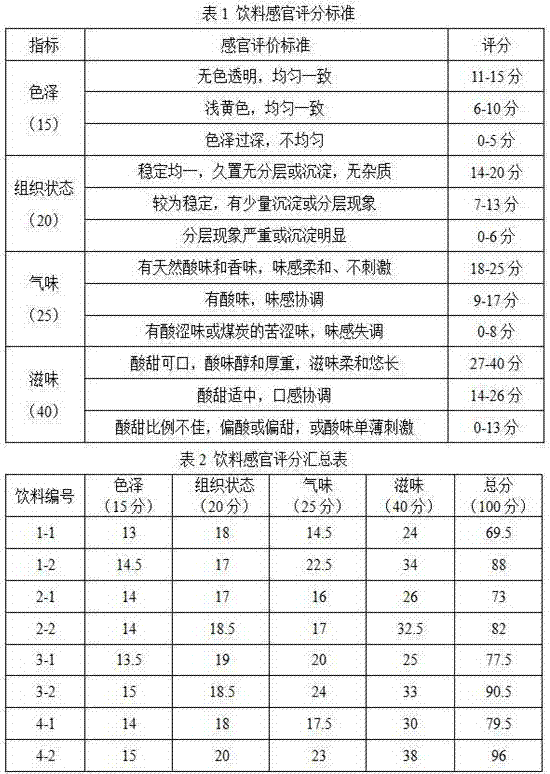

Examples

Embodiment 1

[0020] The components and weight percentages of the young coal degradation liquid flavored beverage in this example are 30% young coal degradation liquid, 3% glucose, 0.01% pectin, 0.02% sodium carboxymethyl cellulose, 0.02% sodium alginate, and the balance is Distilled water.

[0021] Using Yunnan Zhaotong lignite as the raw material, the young coal degradation liquid was prepared according to the method of Example 1 in the patent "A method for producing young coal degradation liquid and its use" (application number: 201410006333.5), which was recorded as sample 1-1. The pH of the degradation liquid is 2.3, and the density is 1.03g / cm 3 .

[0022] Using the same batch of Yunnan Zhaotong lignite as the raw material, the lignite is dried to a moisture content of 15%, crushed and passed through a 200-mesh sieve, and the pulverized coal is ready for use; the coal pulverized coal mass 9.6% potassium permanganate is dissolved in 2 times the pulverized coal mass Add pulverized coal to t...

Embodiment 2

[0027] The components and weight percentages of the young coal degradation liquid flavored beverage in this example are 40% young coal degradation liquid, 5% glucose, 0.01% pectin, 0.06% sodium carboxymethyl cellulose, 0.02% sodium alginate, and the balance is Distilled water.

[0028] Using Yunnan Xundian lignite as the raw material, the young coal degradation liquid was prepared according to the method of Example 1 in the patent "A production method and use of young coal degradation liquid" (application number: 201410006333.5), which was recorded as sample 2-1. The pH value of the degradation liquid is 2.5 and the density is 1.01g / cm 3 .

[0029] Using the same batch of Yunnan Xundian lignite as the raw material, the lignite is dried to a moisture content of 8%, crushed and passed through a 200-mesh sieve, and the pulverized coal is ready for use; the pulverized coal mass 9.6% potassium permanganate is dissolved in twice the pulverized coal mass Add coal powder to deionized wate...

Embodiment 3

[0034] The components and weight percentages of the young coal degradation liquid flavored beverage in this embodiment are 50% young coal degradation liquid, 7% glucose, 0.02% pectin, 0.04% sodium carboxymethyl cellulose, 0.03% sodium alginate, and the balance is Distilled water.

[0035] Using Yunnan Eshan lignite as the raw material, the young coal degradation liquid was prepared according to the method of Example 1 in the patent "A production method and use of young coal degradation liquid" (application number CN201410006333.5), which was recorded as sample 3-1. The pH value of the degradation liquid is 2.1 and the density is 1.03g / cm. 3 .

[0036] Using the same batch of Yunnan Eshan lignite as raw material, the lignite is dried to a moisture content of 10%, crushed and passed through a 200-mesh sieve, and the pulverized coal is ready for use; dissolve 9.6% of the pulverized coal mass in potassium permanganate in 2 times the pulverized coal mass. Add coal powder to the ionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com