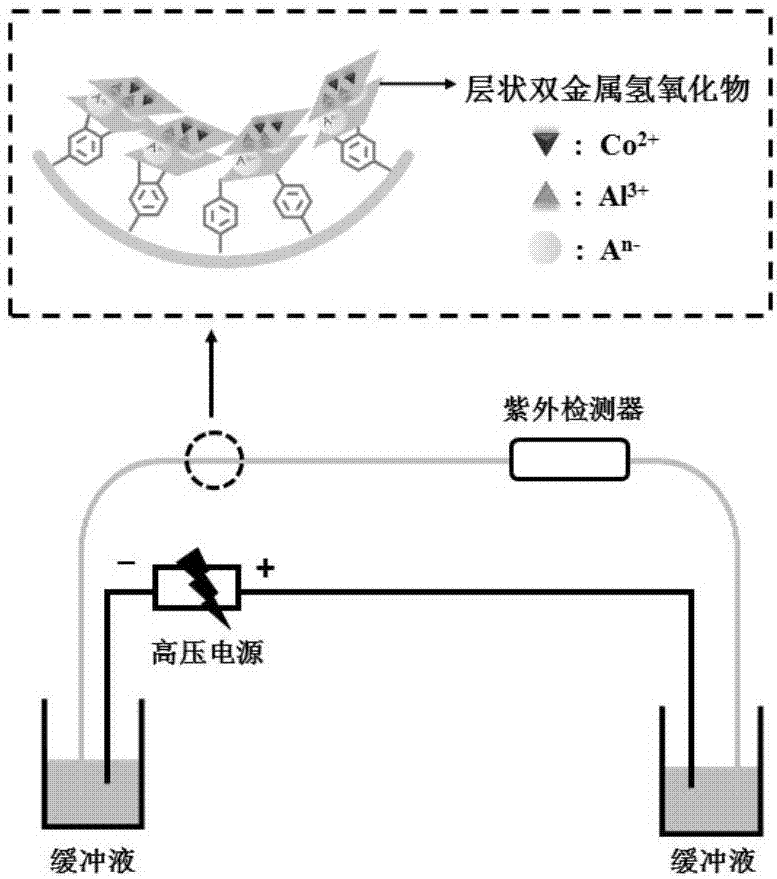

Laminar double-metal hydroxide modified capillary electrochromatography column as well as preparation method and application thereof

A capillary electrochromatography, layered bimetallic technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc. Simple, good stability and reproducibility, good separation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

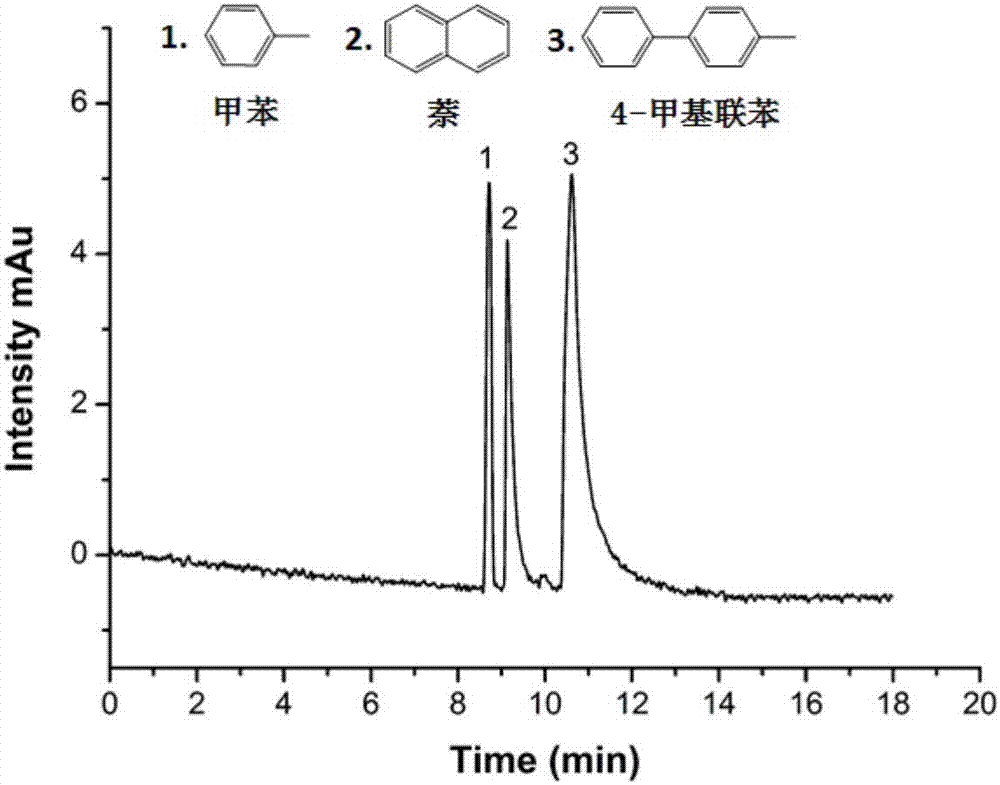

Examples

Embodiment 1

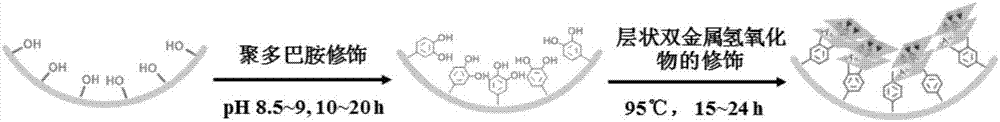

[0029] 1) Take a 50 cm long fused silica capillary (50 µm i.d. × 375 µm o.d.), and wash with NaOH, H 2 O, HCl and H 2 O for preprocessing.

[0030] 2) Weigh 20 mg of dopamine, dissolve it in 10 mmol / L Tris-HCl buffer, adjust the pH to 8.5, shake the pre-oxidized solution to light brown.

[0031] 3) The preoxidized dopamine solution was passed through the capillary pretreated in step 1), the flow rate was 0.03mL / h, and the modification time was 20 h. After washing with water, the solvent was blown off with nitrogen gas, and dried in an oven to obtain a polydopamine-modified capillary column.

[0032] 4) 0.232 g of cobalt nitrate hexahydrate, 0.152 g of aluminum nitrate nonahydrate and 0.168 g of urea were weighed and dissolved in 5 mL of pure water in turn to obtain a reaction solution of layered double metal hydroxide. Then pass this reaction solution into the polydopamine-modified capillary tube obtained after step 3), the two ends of the capillary tube are connected and s...

Embodiment 2

[0034] 1) Take a 50cm long fused silica capillary (50 µm i.d. × 375 µm o.d.), and wash with NaOH, H 2 O, HCl and H 2 O for preprocessing.

[0035] 2) Weigh 20 mg of dopamine, dissolve it in 10 mmol / L Tris-HCl buffer, adjust the pH to 9, shake the pre-oxidized solution to light brown.

[0036] 3) Pass the preoxidized dopamine solution through the capillary pretreated in step 1) at a flow rate of 0.03mL / h and a modification time of 12 h. After washing with water, the solvent was blown off with nitrogen gas, and dried in an oven. Repeat the modification once more to obtain a capillary column with a thicker polydopamine modification layer.

[0037] 4) 0.464 g of cobalt nitrate hexahydrate, 0.304 g of aluminum nitrate nonahydrate and 0.336 g of urea were weighed and dissolved in 5 mL of pure water in turn to obtain a reaction solution of layered double metal hydroxide. Then the reaction solution was passed into the polydopamine-modified capillary column obtained after step 3), ...

Embodiment 3

[0039] 1) Take a 50cm long fused silica capillary (50 µm i.d. × 375 µm o.d.), and wash with NaOH, H 2 O, HCl and H 2 O for preprocessing.

[0040] 2) Weigh 20 mg of dopamine, dissolve it in 10 mmol / L Tris-HCl buffer, adjust the pH to 9, shake the pre-oxidized solution to light brown.

[0041] 3) The preoxidized dopamine solution was passed through the capillary pretreated in step 1), the flow rate was 0.03mL / h, and the modification time was 20 h. After washing with water, the solvent was blown off with nitrogen gas, and dried in an oven. Repeat the modification once more to obtain a capillary column with a thicker polydopamine modification layer.

[0042] 4) 0.058 g of cobalt nitrate hexahydrate, 0.038 g of aluminum nitrate nonahydrate and 0.042 g of urea were weighed and dissolved in 5 mL of water in turn to obtain a reaction solution of layered double metal hydroxide. Then the reaction solution was passed into the polydopamine-modified capillary column obtained after step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com