Method for regulating and controlling residual stress of high-speed rail wheel set tread through high-energy acoustic beams

A residual stress and stress control technology, applied in heat treatment process control, process efficiency improvement, furnace, etc., can solve the problems that the residual stress cannot be eliminated by orbital welding, the accuracy is not high, and there are many influencing factors, and the control time can be achieved. Short, applied stress or residual stress relief, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in detail below:

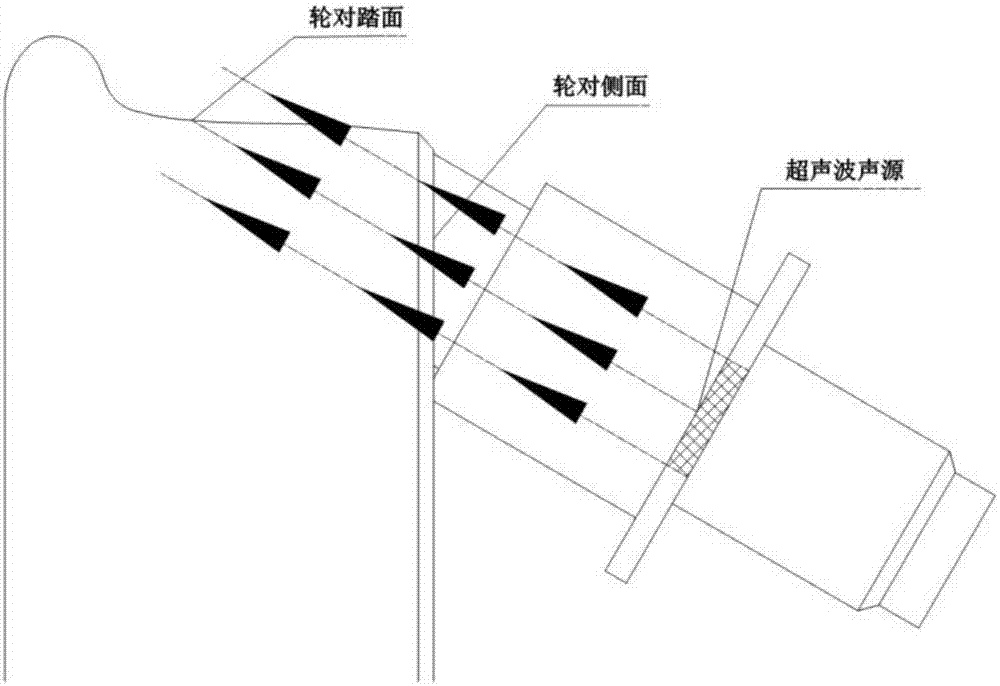

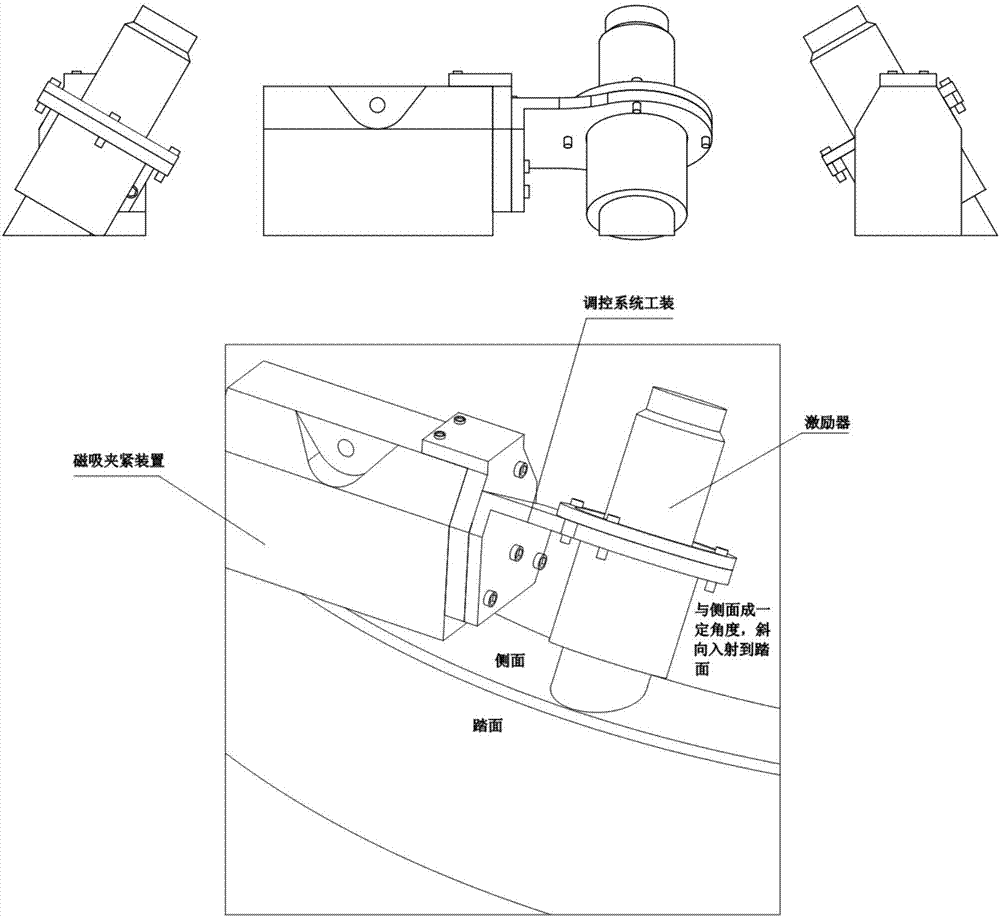

[0012] ①Apply the coupling agent evenly on the residual stress control operation area, and use the transducer magnetic clamping device to tightly and firmly couple the high-energy ultrasonic transducer with the side of the wheel set and keep the coupling contact force constant;

[0013] ② Check the connection status between the excitation voltage transmission cable and the high-energy ultrasonic transducer, and ensure that the power terminal of the high-energy ultrasonic transducer is well connected with one end of the excitation voltage transmission cable;

[0014] ③ Connect the aviation plug at the other end of the excitation voltage transmission cable to the socket behind the high-energy ultrasonic generator correctly, and tighten the aviation plug nut;

[0015] ④ Connect the power supply, turn on the high-energy ultrasonic generator, and adjust the working frequency and voltage on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com