Coal-fired boiler flue gas desulphurization and denitrification device

A coal-fired boiler and flue gas technology, applied in the field of coal-fired boiler flue gas desulfurization and denitrification equipment, flue gas desulfurization and denitrification equipment, can solve the problems of low removal efficiency of compound pollutants, complex preparation of lime slurry, inconvenient transportation and storage, etc. , to achieve the effects of small footprint, easy maintenance, and low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

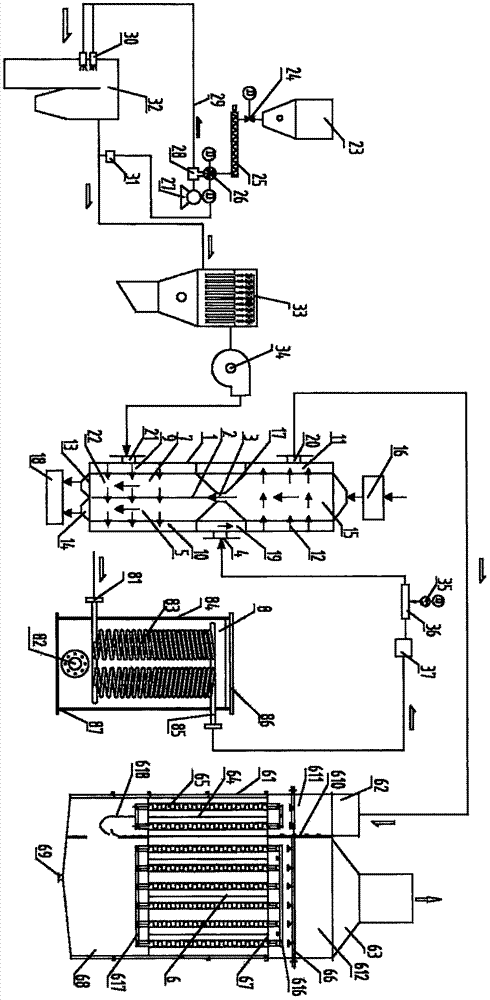

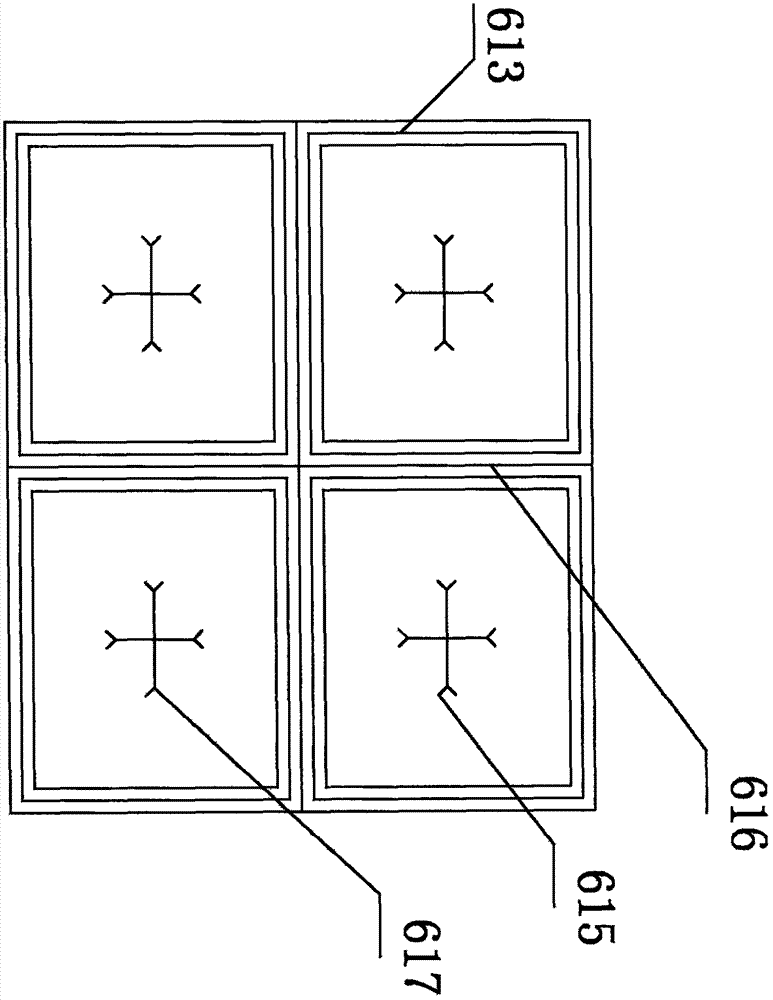

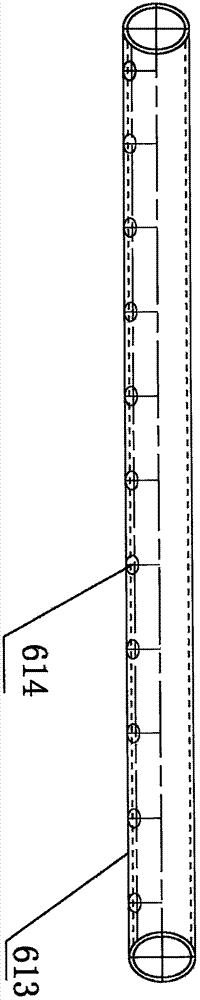

[0014] Such as figure 1 , figure 2 , image 3As shown, the present invention is a coal-fired boiler flue gas desulfurization and denitrification device, including a coal-fired boiler 32, a flue gas online monitoring and control device 31, a bag filter 33, a fan 34, an adsorption reactor 1, and a water-bath ammonia gasification 8, wet electrostatic precipitator 6, characterized in that: the coal-fired boiler 32 is connected to the flue gas online monitoring and control device 31, the bag filter 33, the fan 34, the adsorption reactor 1, and the water-bath ammonia gasifier 8 through pipelines . Wet electrostatic precipitator 6, the flue gas online monitoring and control device 31 is connected to the frequency conversion rotary feeder 26, the top of the frequency conversion rotary feeder 26 is connected to the electronic screw scale 25, and the electronic screw scale 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com