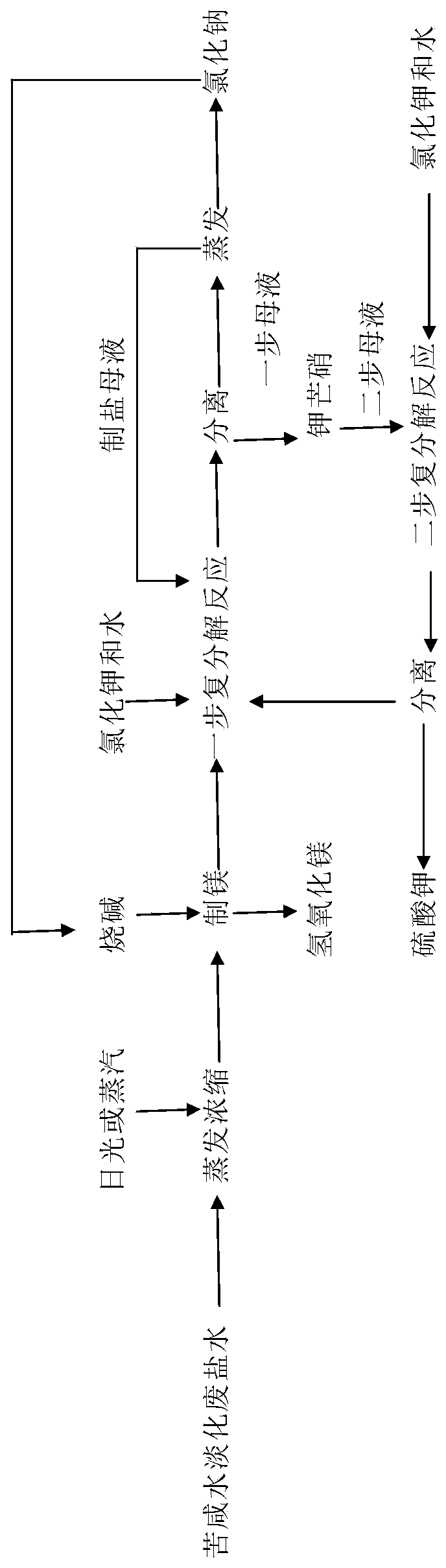

A Circular Economy Process for Co-production of Waste Brine, Magnesium, Potassium, Salt and Alkali from Brackish Water Desalination

A technology for desalination of brackish water and waste salt water, which is applied in the field of circular economy technology, can solve problems such as circular salinization of land, and achieve the effects of no three wastes discharge, reasonable product scheme, and innovative process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: take 1000m 3 Brackish water desalination by-product waste brine (containing NaCl 30.00g / l, MgSO 4 15.00g / l, KCl 1.00g / l) as raw materials, the waste brine was evaporated (evaporating temperature 25°C) to obtain 125m 3 Concentrated mother liquor (containing NaCl 240g / l, MgSO 4 120g / l, KCl 8.0g / l) add 10 tons of caustic soda (NaOH) and carry out normal temperature reaction (reaction time 2 hours) obtain 7.25 tons of magnesium hydroxide products and 125m 3 Magnesium mother liquor (NaCl 240g / l, Na 2 SO 4 142g / l, KCl 8.0g / l); 125m 3 Magnesium-making mother liquor is mixed with circulating salt-making mother liquor and circulating two-step mother liquor and adds 13.875 tons of potassium chloride and water to carry out one-step double decomposition normal temperature reaction (reaction time 2 hours) and obtains 48.9375 tons of potassium mirabilite intermediate product and one-step mother liquor; One-step mother liquor mixes high-temperature evaporation ( ...

Embodiment 2

[0022] Embodiment 2: take 1000m 3 Brackish water desalination by-product waste brine (containing NaCl 150.00g / l, MgSO 4 75.00g / l, KCl 5.00g / l) as raw materials, the waste brine was evaporated (evaporating temperature 105°C) to obtain 625m 3 Concentrated mother liquor (containing NaCl240g / l, MgSO 4 120g / l, KCl 8.0g / l) add 50 tons of caustic soda (NaOH) and carry out normal temperature reaction (reaction time 2 hours) obtain 36.25 tons of magnesium hydroxide products and 625m 3 Magnesium mother liquor (NaCl 240g / l, Na 2 SO 4 142g / l, KCl 8.0g / l); 625m 3 Magnesium making mother liquor is mixed with circulating salt making mother liquor and circulating two-step mother liquor, and 69.375 tons of potassium chloride and water are added to carry out one-step double decomposition normal temperature reaction (reaction time 2 hours) to obtain 244.6875 tons of potassium Glauber's salt intermediate product and one-step mother liquor; One-step mother liquor is mixed and evaporated at ...

Embodiment 3

[0023] Embodiment 3: take 1000m 3 Brackish water desalination by-product waste brine (containing NaCl 90.00g / l, MgSO 4 45.00g / l, KCl 3.00g / l) as raw materials, the waste brine was evaporated (evaporating temperature 25°C) to obtain 375m 3 Concentrated mother liquor (containing NaCl 240g / l, MgSO 4 120g / l, KCl 8.0g / l) add 30 tons of caustic soda (NaOH) and carry out normal temperature reaction (reaction time 2 hours) obtain 21.75 tons of magnesium hydroxide products and 375m 3 Magnesium mother liquor (NaCl 240g / l, Na 2 SO 4 142g / l, KCl 8.0g / l); 375m 3 Magnesium mother liquor is mixed with circulating salt-making mother liquor and circulating two-step mother liquor, and 41.625 tons of potassium chloride and water are added to carry out one-step double decomposition normal temperature reaction (reaction time 2 hours) to obtain 146.8125 tons of potassium mirabilite intermediate product and one-step mother liquor; One-step mother liquor is mixed and evaporated at high tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com