High-voltage lithium ion battery

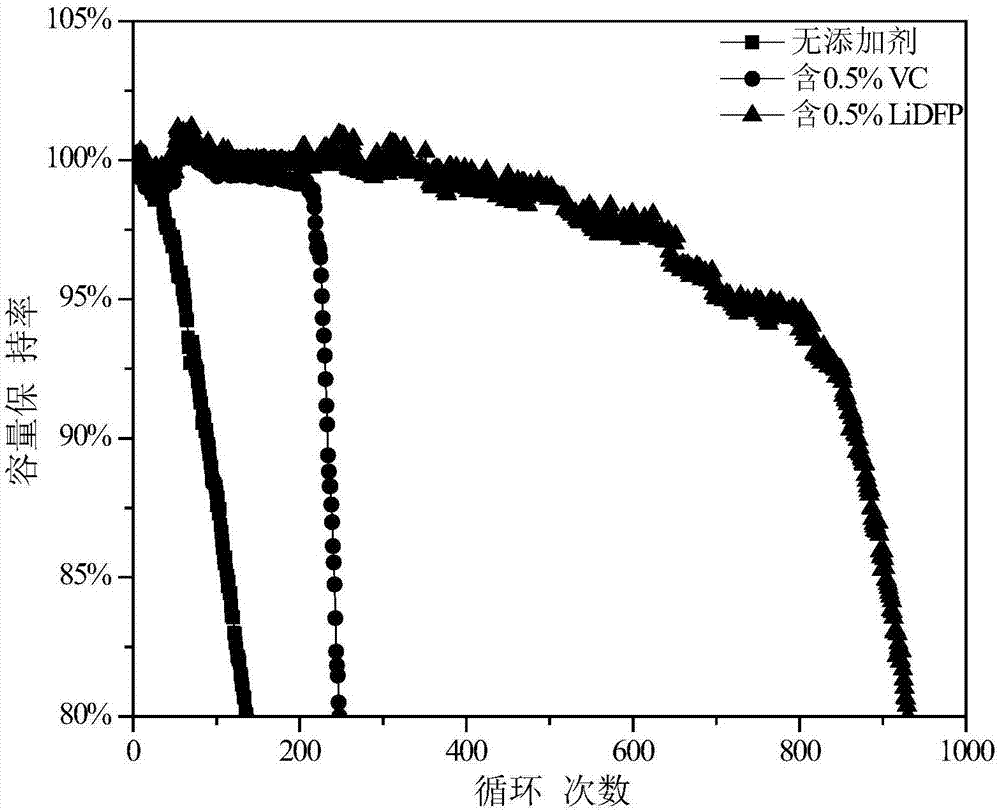

A lithium-ion battery, high-voltage technology, applied in the field of lithium-ion batteries, can solve the problems of increasing irreversible capacity loss, shortening battery cycle life, reducing Coulomb efficiency, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

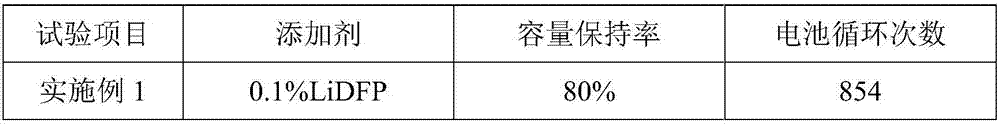

Embodiment 1

[0020] The assembly process of the full battery is as follows:

[0021] (1) Preparation of positive pole piece: LiNi, a ternary material suitable for high voltage after coating 0.5 co 0.2 mn 0.3 o 2 As the positive active material, 95.5% LiNi 0.5 co 0.2 mn 0.3 o 2 , 1.5% conductive agent Super-P, 1.5% conductive agent KS-6, and 1.5% binder PVDF are mixed to make positive electrode slurry and evenly coated on positive electrode current collector aluminum foil. Bake in an oven until the weight loss ratio of the positive pole piece is <0.2%, then cut into large pieces, then cut into small pieces, weld the aluminum tabs, and paste high-temperature adhesive tape on the aluminum tabs to obtain the positive pole pieces;

[0022] (2) Negative electrode sheet preparation: use composite graphite as the negative electrode active material, mix 95.0% composite graphite, 1.5% conductive agent Super-P, 1.5% dispersant CMC and 2% binder SBR to make the negative electrode The slurry is...

Embodiment 2

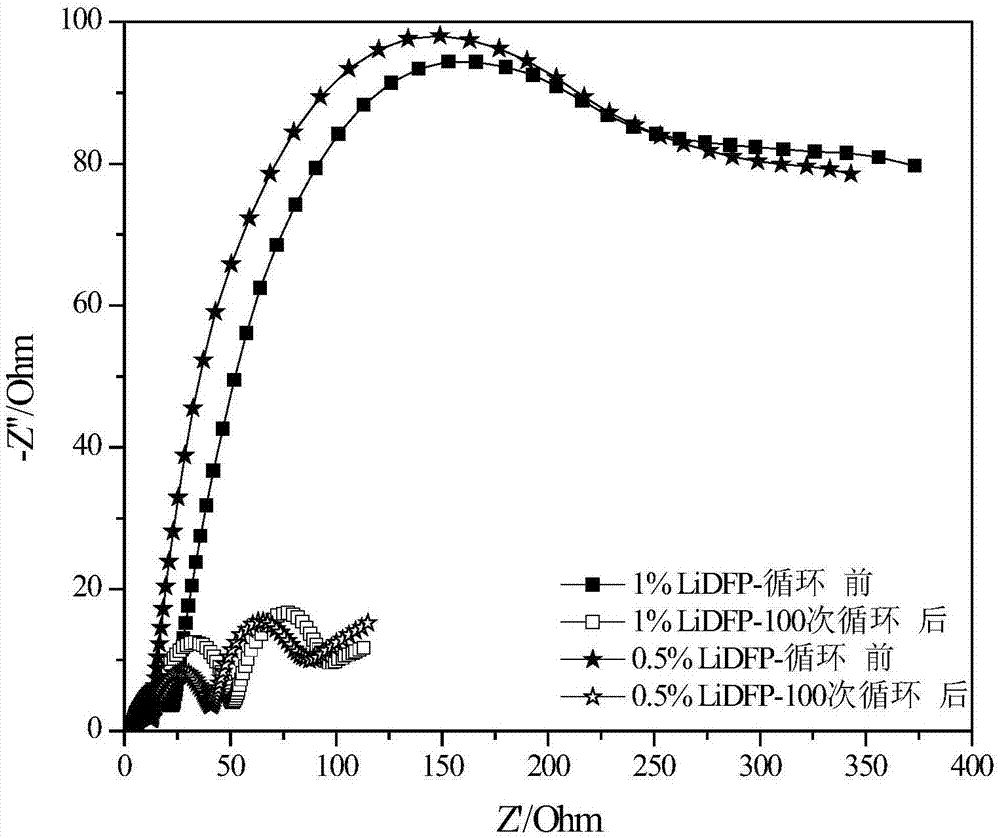

[0026] Except that the composition of the electrolyte is different, the rest of the high-voltage lithium-ion battery is the same as that of Example 1.

[0027] The composition of the electrolyte is as follows: the lithium salt is LiPF 6 , and the concentration of the lithium salt is 1mol / L; the non-aqueous organic solvent is ethylene carbonate and ethyl methyl carbonate (the mass ratio of the two is 3:7); the additive is LiDFP, which accounts for 0.3% of the total mass of the electrolyte.

Embodiment 3

[0029] Except that the composition of the electrolyte is different, the rest of the high-voltage lithium-ion battery is the same as that of Example 1.

[0030] The composition of the electrolyte is as follows: the lithium salt is LiPF 6 , and the concentration of the lithium salt is 1mol / L; the non-aqueous organic solvent is ethylene carbonate and ethyl methyl carbonate (the mass ratio of the two is 3:7); the additive is LiDFP, which accounts for 0.5% of the total mass of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com