Flue gas denitrification device of coal-fired boiler

A coal-fired boiler and denitration technology, applied in the field of flue gas denitration equipment and coal-fired boiler flue gas denitration device, can solve problems such as hazards, and achieve the effects of reducing environmental pollution, low energy consumption, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

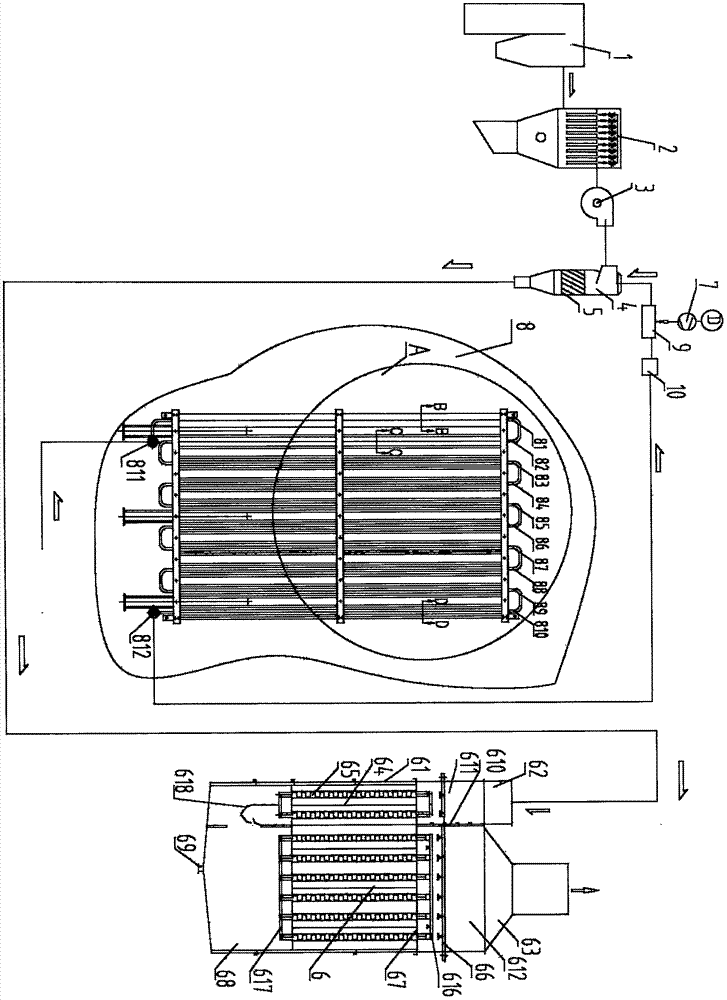

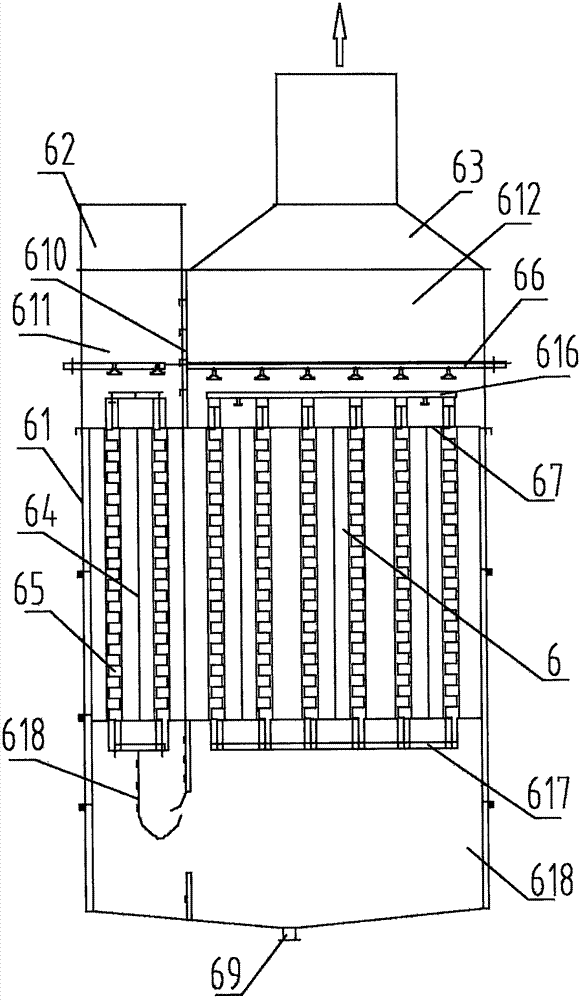

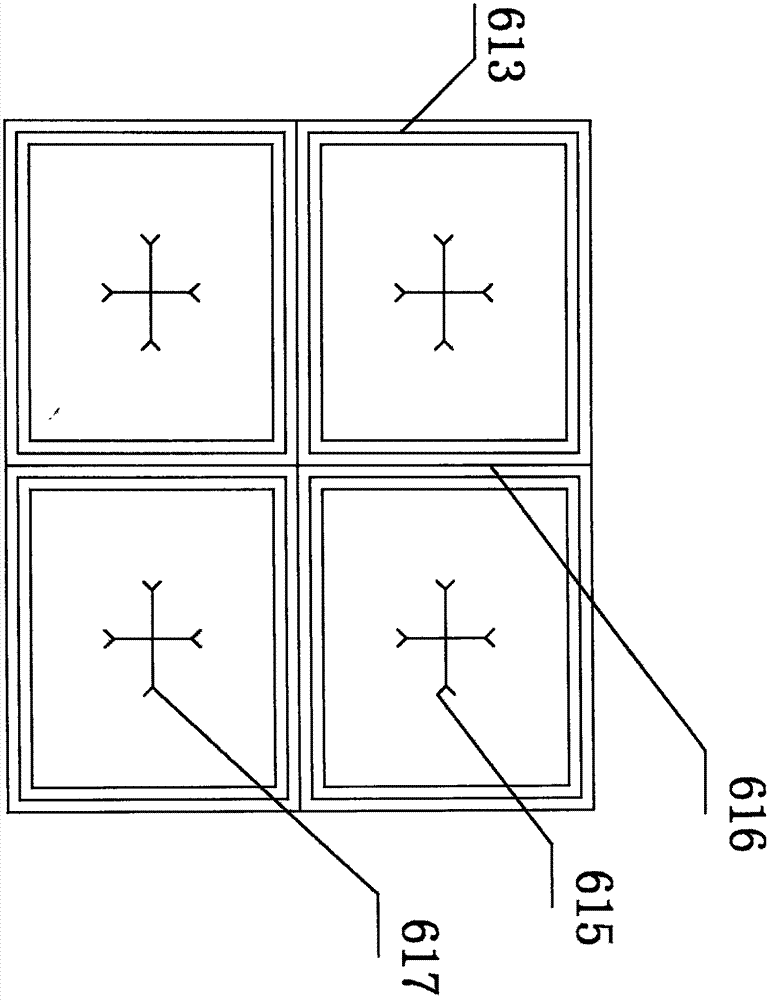

[0022] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11As shown, the present invention is a coal-fired boiler flue gas denitrification device, comprising a coal-fired boiler 1, a bag filter 2, a fan 3, an SCR reactor 4, an ammonia gasifier 8, and a wet electrostatic precipitator 6, characterized in that : the coal-fired boiler 1 is connected to the bag filter 2, the fan 3, the SCR reactor 4, the ammonia gasifier 8, and the wet electrostatic precipitator 6 through pipelines, and a catalyst layer 5 is arranged in the middle of the SCR reactor 4, and the SCR reaction The upper part of the device 4 is connected with the ammonia / air mixer 9, and the ammonia / air mixer 9 is connected with the diluted ammonia blower 7 one way, and the other way is connected with the outlet of the amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com