Flotation technology for efficiently recycling complex copper oxide ore

A copper oxide ore, flotation technology, applied in flotation, solid separation, etc., to achieve good flotation index, prevent activity failure, and high-grade effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1

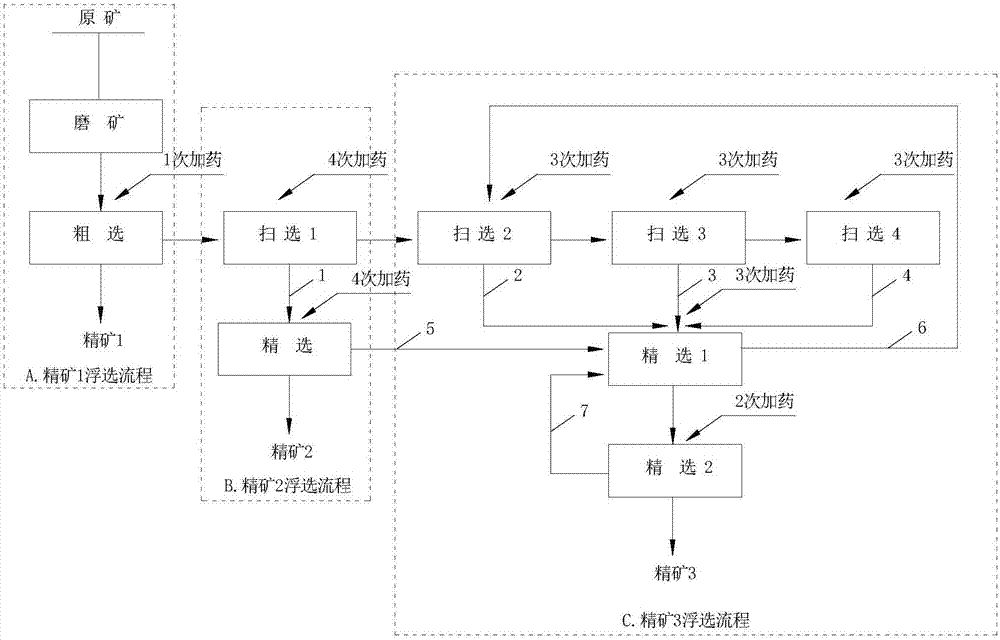

[0026] Please check figure 1 In this embodiment, the main valuable element of the raw ore is copper, with a mass fraction of 5.90%, the mass fraction of iron is 1.03%, and the mass fraction of sulfur is 0.053%.

[0027] A kind of flotation process of efficiently reclaiming complex copper oxide ore of the present embodiment comprises the following steps:

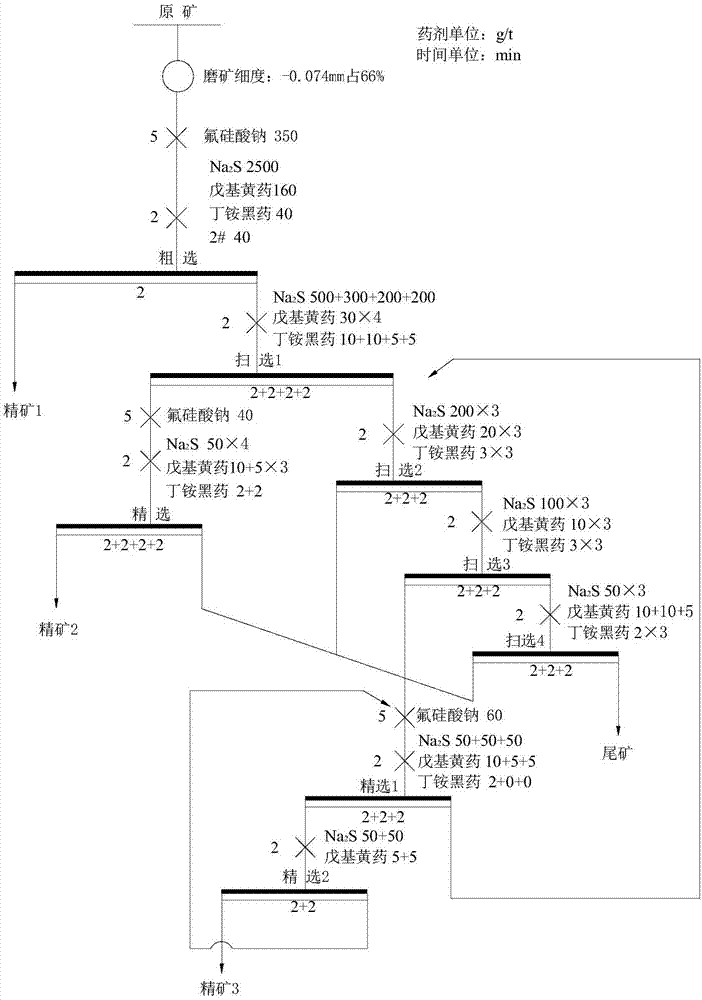

[0028] A. Concentrate-flotation process: Grind the raw ore until the grinding fineness is -0.074mm, and the mass fraction is 60-70%, and then add sodium fluorosilicate after making it into slurry, the dosage is 350g / t; the activator uses vulcanization Sodium, the dosage is 2500g / t, to activate copper oxide ore; the collector uses compound collector amyl xanthate 160g / t and butylamine black medicine 40g / t, foaming agent uses 2 # Oil 40g / t, carry out rapid flotation for 2 minutes to obtain concentrate one and roughing slag;

[0029] B. Concentrate 2 flotation process: Sweeping 1 and selecting 1 of the abov...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is: the main valuable element of the raw ore used in this embodiment is copper, the mass fraction is 5.95%, the mass fraction of iron element is 1.15%, and the mass fraction of sulfur element is 0.061%.

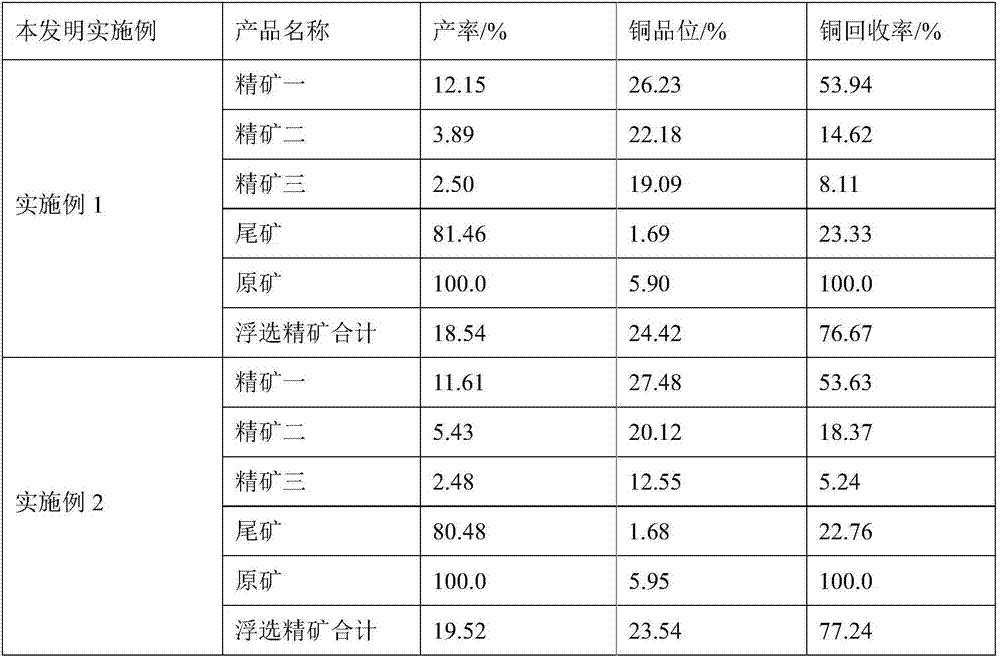

[0042] Please refer to the following table 1, the results of embodiment 1 and embodiment 2 shown in the table show that, adopting the flotation process of the present invention to efficiently reclaim copper oxide ore, the raw ore copper grade in embodiment 1 is 5.90%, and the yield is 12.15%, a high-grade copper concentrate with a copper grade of 26.23% and a copper recovery of 53.94% (i.e. concentrate one); a yield of 3.89%, a copper grade of 22.18%, and a copper recovery of 14.62% for a medium-grade copper Concentrate (i.e. Concentrate II); yield rate is 2.50%, copper grade is 19.09%, copper recovery rate is 8.11% low-grade copper concentrate (i.e. Concentrate III); mixed copper concentrate yield is 18.54%, grade I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com