Circulating municipal sludge treatment system and method thereof

An urban sludge and treatment system technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. To achieve the effect of improving efficiency and pertinence, improving efficiency and effect, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

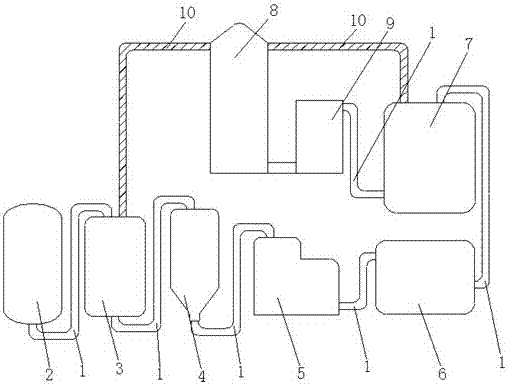

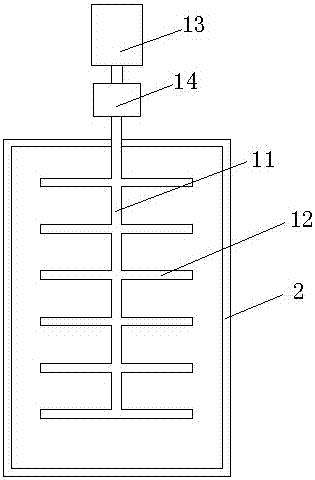

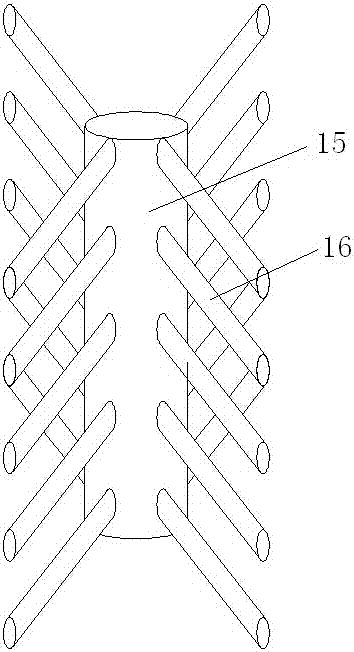

[0033] Such as Figure 1-5 As shown, a recyclable municipal sludge treatment system includes a passivation kettle 2 connected with a sludge discharge pipe 1, a high-temperature hydrolysis acidification reaction tank 3, a gravity concentration tank 4, a crusher 5, and a dehydration filter press 6. And drier 7, and desulfurization tower 8 and water collection tank 9, described high-temperature hydrolysis acidification reaction tank 3 and drier 7 are respectively connected with the air inlet of desulfurization tower 8 by waste gas pipe 10, and described drier 7 is provided with A steam heating mechanism, the steam heating mechanism is connected to the water inlet of the water collecting tank 9 , and the water outlet of the water collecting tank 9 is connected to the water inlet of the desulfurization tower 8 .

[0034] The passivation kettle 2 is provided with a stirrer, which can fully contact the heavy metal passivation material with the heavy metal in the sludge, and improve t...

Embodiment 2

[0053] A recyclable municipal sludge treatment method is characterized in that: comprising the following specific steps:

[0054] (1) Heavy metal passivation: Pour the sludge into the passivation kettle, then add the passivation agent into the passivation kettle 2, start the agitator, and fully mix the passivation agent and the sludge;

[0055] The passivation agent is quicklime, fly ash or clay, which can be added to the passivation tank to increase the pH value of the sludge, convert heavy metals into hydroxides and other precipitates, and achieve the effect of passivating metals and killing the original bacteria.

[0056] (2) Hydrolytic acidification: Add the sludge after the reaction in (1) into the high-temperature hydrolytic acidification reaction tank, and heat it with an electric heater at a temperature of 35-55°C for 3-5 days;

[0057] High-temperature hydrolytic acidification can increase the wall breaking rate of microbial cell walls in sludge, so as to fully releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com