Emamectin benzoate granule and preparation method of same

A technology of emamectin and benzoate, which is applied in the field of pesticides, can solve the problems of imperfect manufacturing technology, etc., and achieve the effect of ideal drug effect, good practicability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

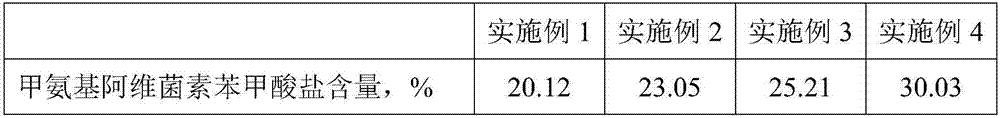

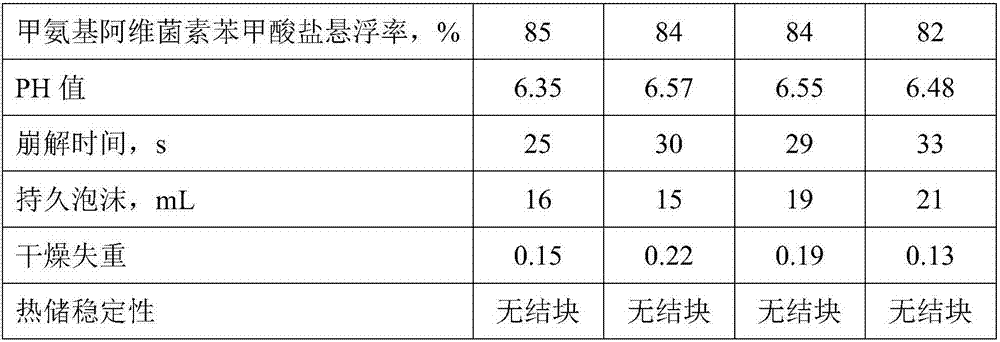

Embodiment 1

[0020] A kind of production method of emamectin benzoate granule mainly is the former medicine of emamectin benzoate and dispersion agent, wetting agent (sulfonate surfactant), Binders (glucose and lactose), disintegrants (thiamine) and fillers are fully mixed and powdered to the target particle size to form finished granules. Specific steps are as follows:

[0021] 1) Mixing and powdering: close the bottom valve of the mixer, open the feed port of the mixer, put in 20kg of the original drug of emamectin benzoate, and 8kg of dispersant (the dispersant is mainly polycarboxylate and naphthalenesulfonic acid Salt), wetting agent 4kg, disintegrant 23kg, binder 8kg and filler 37kg (the filler in this project is mainly corn starch), and the feeding is completed and stirred for 60min; The coarse powder is collected into the middle hopper, and then the jet mill is turned on for crushing. The screw feeding frequency is 8Hz, the jet mill pressure is 0.8MPa, the jet mill frequency is 50...

Embodiment 2

[0024] A kind of production method of emamectin benzoate granule, concrete steps are as follows:

[0025] 1) Mixing and powdering: close the bottom valve of the mixer, open the feed port of the mixer, put in 23kg of the original drug of emamectin benzoate, and 8kg of dispersant (the dispersant is mainly polycarboxylate and naphthalenesulfonic acid Salt), wetting agent 4kg, disintegrant 25kg, binder 10kg and filler 30kg (the filler in this project is mainly corn starch), and the feeding is completed and stirred for 60min; The coarse powder is collected into the middle hopper, and then the jet mill is turned on for crushing. The screw feeding frequency is 8Hz, the jet mill pressure is 0.8MPa, the jet mill frequency is 50Hz, and the crushing particle size is controlled to 8-10μm.

[0026] 2) Granulation and drying: Put the pulverized material into the mixer, spray 5kg of deionized water, stir for 30 minutes, and then discharge it to the conveyor belt, transfer it to the hopper of...

Embodiment 3

[0028] A kind of production method of emamectin benzoate granule, concrete steps are as follows:

[0029] 1) Mixing and powdering: close the bottom valve of the mixer, open the feed port of the mixer, put in 25kg of the original medicine of emamectin benzoate, and 10kg of dispersant (the dispersant is mainly polycarboxylate and naphthalenesulfonic acid Salt), wetting agent 4kg, disintegrant 23kg, binder 8kg and filler 30kg (the filler in this project is mainly corn starch), and the feeding is completed and stirred for 60min; The coarse powder is collected into the middle hopper, and then the jet mill is turned on for crushing. The screw feeding frequency is 8Hz, the jet mill pressure is 0.8MPa, the jet mill frequency is 50Hz, and the crushing particle size is controlled to 8-10μm.

[0030] 2) Granulation and drying: Put the pulverized material into the mixer, spray 5kg of deionized water, stir for 30 minutes, and then discharge it to the conveyor belt, transfer it to the hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com