Manufacture technology of procambarus clarkii food

A production process, lobster technology, applied in the direction of food science, etc., can solve the problems of poor taste, short shelf life of crayfish food, and inability to eat ready-to-eat, etc., to achieve long shelf life, ensure the effect of irradiation and prolong the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

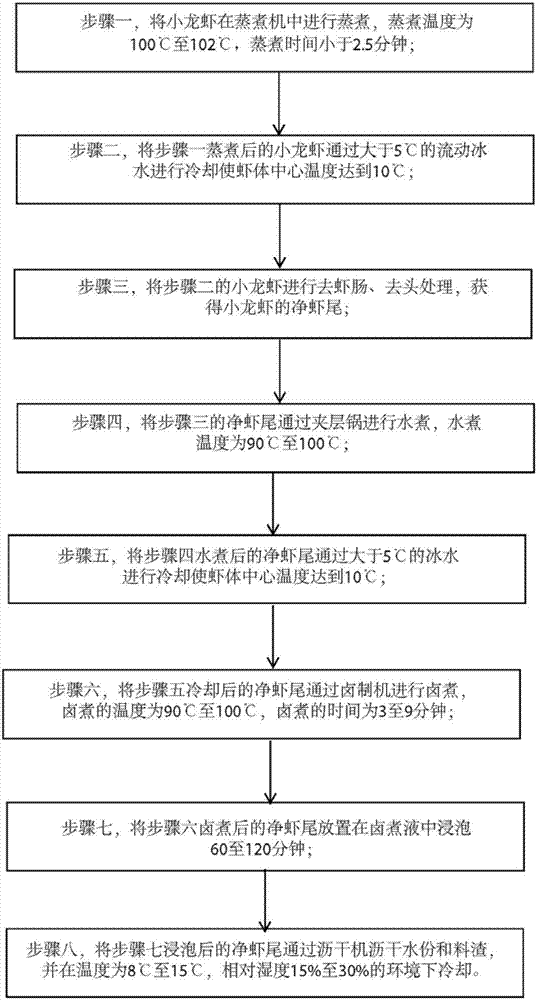

[0067] Step 1, steaming the crayfish;

[0068] Step 2, cooling the crayfish after cooking in step 1;

[0069] Step 3, processing the cooled crayfish in step 2 to obtain net shrimp tails;

[0070] Step 4, boil the net shrimp tails in Step 3;

[0071] Step 5, cooling the net shrimp tails boiled in step 4 again;

[0072] Step 6, frying the cooled net shrimp tails in step 5 and de-oiling after frying;

[0073] Step seven, seasoning the net shrimp tails in step six to obtain crayfish food.

[0074] Such as figure 1 As shown, in the first step, the crayfish is cooked in a cooking machine, the cooking temperature is 100°C to 102°C, and the cooking time is less than 2.5 minutes;

[0075] In said step 2, the crayfish cooked in step 1 is cooled by flowing ice water greater than 5°C so that the temperature of the center of the shrimp body reaches 10°C;

[0076] In said step 3, the crayfish in step 2 are subjected to the process of removing the shrimp intestines and heads, so as to ...

specific Embodiment 2

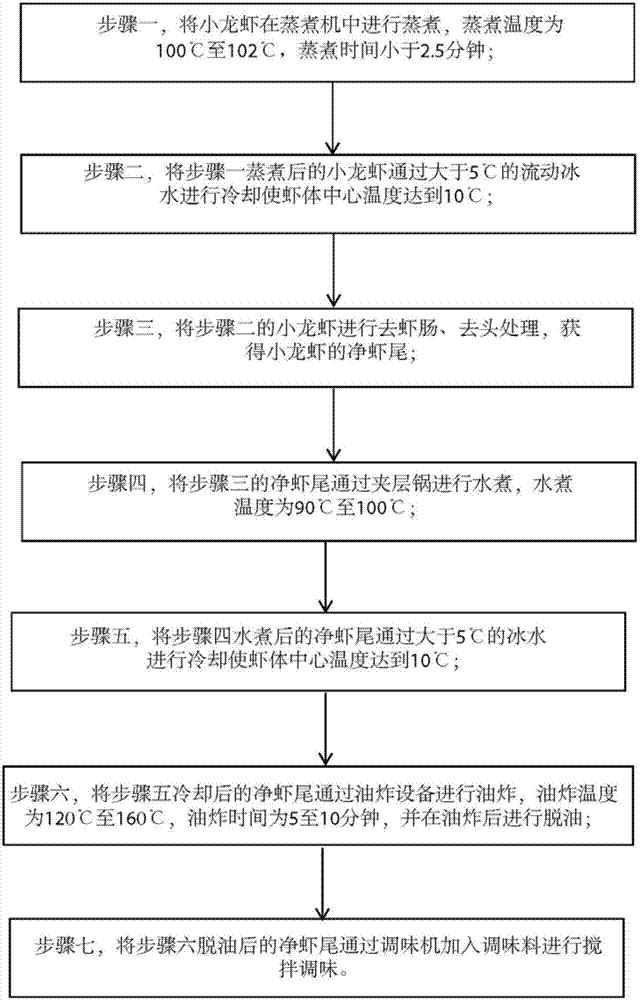

[0108] Step 1, steaming the crayfish;

[0109] Step 2, cooling the crayfish after cooking in step 1;

[0110] Step 3, processing the cooled crayfish in step 2 to obtain net shrimp tails;

[0111] Step 4, boil the net shrimp tails in Step 3;

[0112] Step 5, cooling the net shrimp tails boiled in step 4 again;

[0113] Step 6, frying the cooled net shrimp tails in step 5 and de-oiling after frying;

[0114] Such as figure 2 As shown, in the first step, the crayfish is cooked in a cooking machine, the cooking temperature is 100°C to 102°C, and the cooking time is less than 2.5 minutes;

[0115] In said step 2, the crayfish cooked in step 1 is cooled by flowing ice water greater than 5°C so that the temperature of the center of the shrimp body reaches 10°C;

[0116] In said step 3, the crayfish in step 2 are subjected to the process of removing the shrimp intestines and heads, so as to obtain the net shrimp tails of the crayfish;

[0117] In the step four, the net shrimp t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com