Dissimilar steel welding method

A welding method and dissimilar steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as thermal cracks and embrittlement of welded joints, and achieve the goal of reducing brittleness, improving plasticity and toughness, and increasing content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

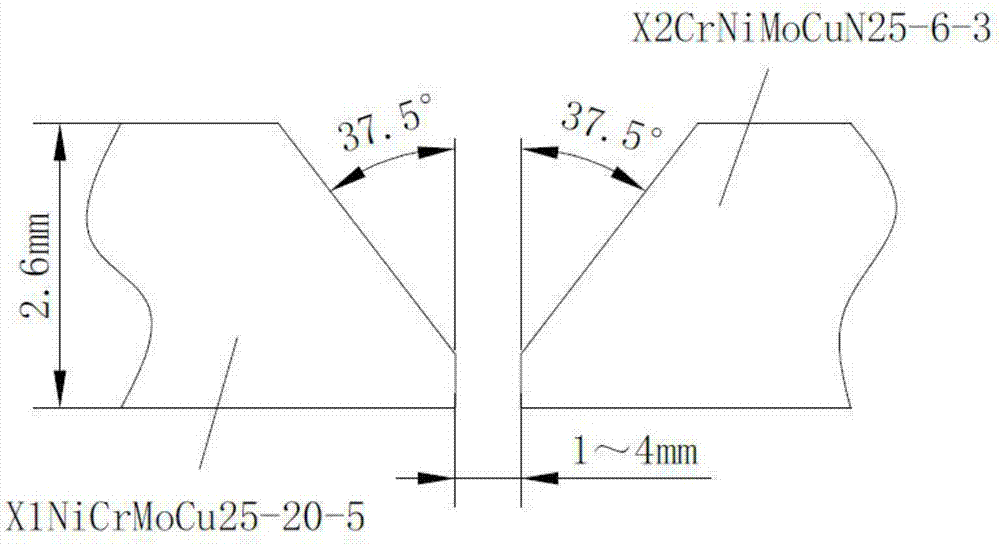

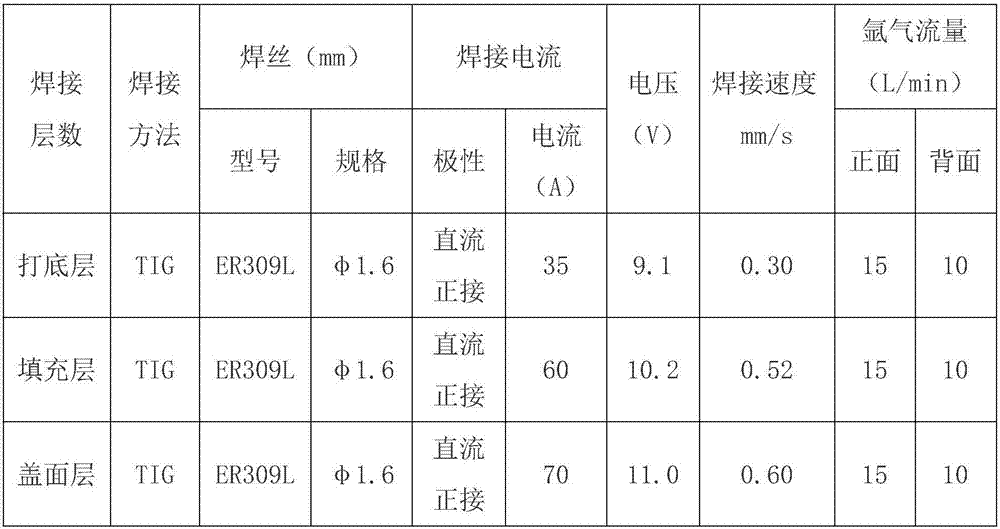

[0032] Example 1, a section of X1NiCrMoCu25-20-5 steel plate base material with a thickness of 2.6mm and a section of X2CrNiMoCuN25-6-3 steel plate base material with a thickness of 2.6mm are selected. First, the welding parts of the two sections of X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base materials to be welded are processed into a 37.5° V-shaped groove, and the surface of the groove and the grooves within 20mm around the groove The inner and outer surfaces of the base metal are cleaned, including cleaning of impurities and oil and grinding the surface of the base metal until metallic luster appears. Next, group the X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base materials that have completed the groove processing, and control the gap between the groups between 1 and 4mm. Then, according to the welding parameters in Table 1, the ER309L welding wire with a diameter of φ1.6mm was selected, and the X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissim...

Embodiment 2

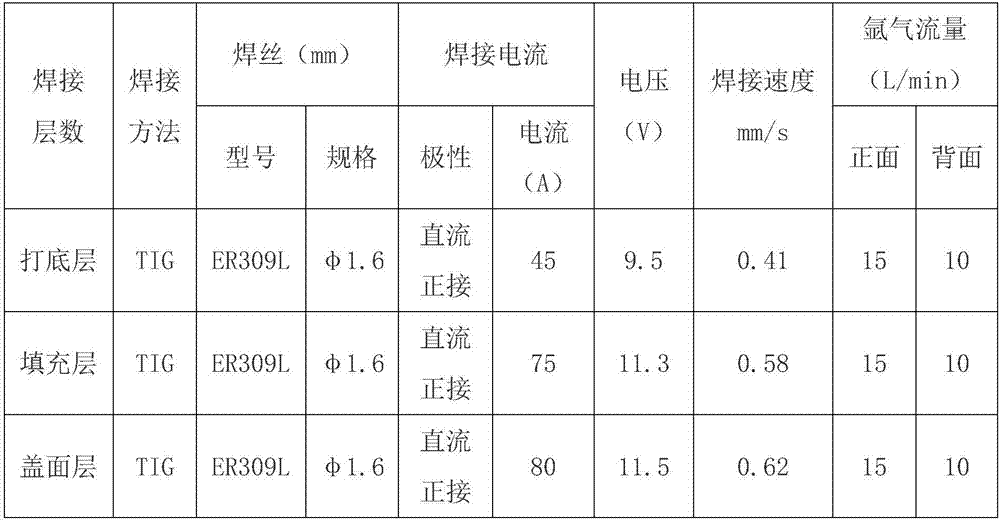

[0035]Embodiment 2, adopt the welding method identical with embodiment 1 to carry out welding operation to X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base material, and its difference is: embodiment 2 adopts the welding parameter in table 3 to X1NiCrMoCu25- 20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base metals are welded; at the same time, the interlayer temperature is controlled to 170 °C. Finally, the welding product X2 is obtained.

[0036] table 3

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com