Preparation method of nitrate radical intercalation lithium-aluminum layered bimetal hydroxide

A layered bimetallic and nitrate intercalation technology, applied in the fields of aluminum compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficulties, low product crystallinity, complicated and cumbersome operation process, etc., and achieve simple operation and crystallization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a nitrate-intercalated lithium-aluminum layered double hydroxide, comprising:

[0026] Lithium nitrate, aluminum nitrate, and precipitant are added to water, and the reaction mixture is obtained after dissolving;

[0027] React the reaction mixture at 120-160°C (hydrothermal) for 24-48 hours;

[0028] After the reaction is finished, the precipitate is separated, washed and dried to obtain a nitrate-intercalated lithium-aluminum layered double metal hydroxide.

[0029] The inventors of the present invention have found through research that lithium-aluminum layered double hydroxides intercalated with nitrate can be synthesized in one step by using a uniform precipitation method and hydrothermal reaction.

[0030] In a specific embodiment of the present invention, lithium nitrate, aluminum nitrate and precipitating agent can be dissolved in water to obtain a reaction mixture, and then the reaction mixture is transferred to a h...

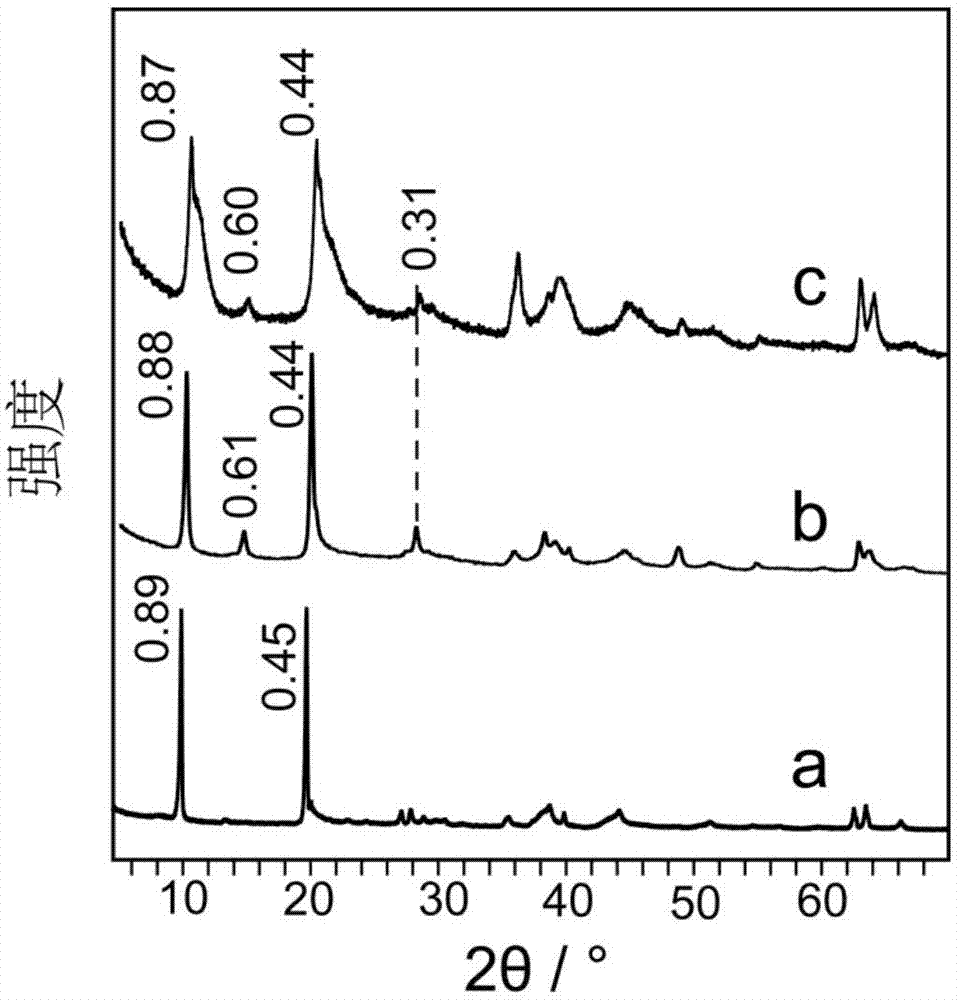

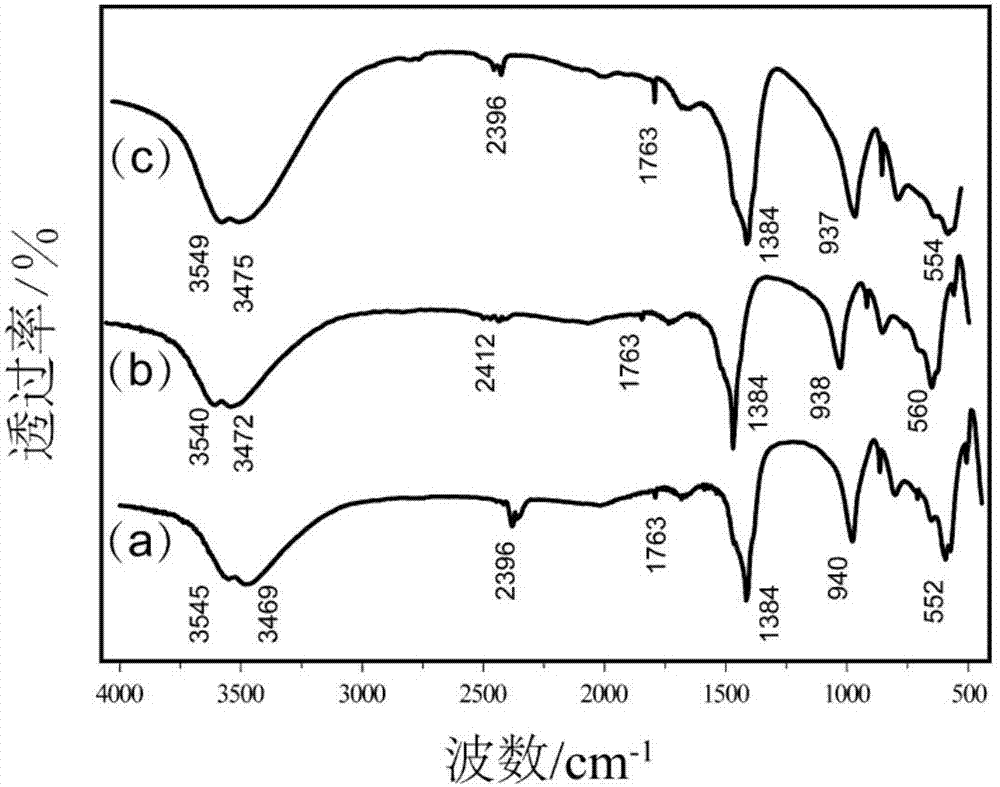

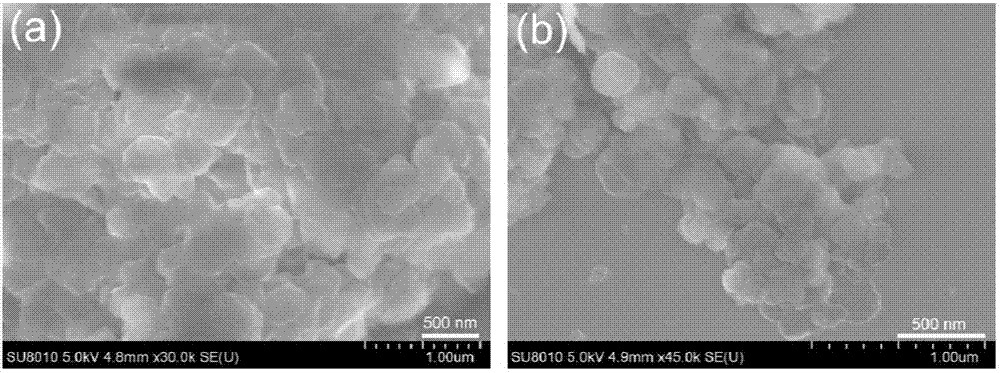

Embodiment 1

[0039] Weigh 4.14g LiNO respectively 3 (0.06mol, 1.2M), 7.50g Al(NO 3 ) 3 9H 2 O (0.02mol, 0.4M), urea 1.44g (0.024mol, 0.48M), feed ratio Li:Al:CO(NH 2 ) 2 = 3:1:1.2. Dissolve in 50mL deionized water, put in a hydrothermal kettle, and react at 120°C for 48 hours. The resulting precipitate (product) was filtered, washed three times with deionized water, dried at 40° C. for 24 hours, and ground to obtain a white powder.

Embodiment 2

[0041] Weigh 4.14g LiNO respectively 3 (0.06mol, 1.2M), 7.50g Al(NO 3 ) 3 9H 2 O (0.02mol, 0.4M), urea 1.92g (0.032mol, 0.64M), feed ratio Li:Al:CO(NH 2 ) 2 = 3:1:1.6. Dissolve in 50mL deionized water, put in a hydrothermal kettle, and react at 120°C for 48 hours. The resulting precipitate (product) was filtered, washed three times with deionized water, dried at 40° C. for 24 hours, and ground to obtain a white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com