Calcium-zinc liquid stabilizing agent and preparation method thereof

A liquid stabilizer, calcium-zinc technology, applied in the field of calcium-zinc liquid stabilizer and its preparation, can solve the problems of incomplete reaction, product introduction of impurities, insufficient heat resistance, etc., achieve complete reaction, improve product hygiene, avoid The effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

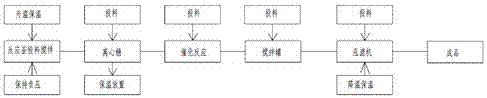

Image

Examples

Embodiment 1

[0018] A calcium-zinc liquid stabilizer, consisting of the following raw materials in parts by weight: calcium hydroxide 80; zinc oxide 20; oleic acid 32; isooctanoic acid 12; nonylphenol 15; triethylene glycol 17; benzoic acid 23; 25 base benzoic acid; white oil 13; solvent oil 10; D40 oil 11; H80 oil 10; aviation kerosene 15; triphenyl phosphite 14; 3; Bisphenol A45; Dibenzoylmethane11.

[0019] The preparation steps are as follows:

[0020] (1) Add oleic acid, isooctanoic acid, benzoic acid, triethylene glycol, p-tert-butylbenzoic acid, and diethylene glycol butyl ether into the reactor, and then stir under the conditions of reactor pressure -0.08Mpa and temperature 50°C uniform.

[0021] (2) Add white oil, solvent oil, D40 oil, and H80 oil to the mixed liquid produced in step 1, place it in a centrifuge barrel at a speed of 2000r / min, and a centrifugal force of 2780Xg for 1 minute, take it out, and place it in a closed environment at a temperature of 30°C Put it down fo...

Embodiment 2

[0026] A calcium-zinc liquid stabilizer, consisting of the following raw materials in parts by weight: calcium hydroxide 112; zinc oxide 45; oleic acid 56; isooctanoic acid 32; nonylphenol 25; triethylene glycol 26; benzoic acid 45; 30 base benzoic acid; 24 white oil; 15 solvent oil; 18 D40 oil; 14 H80 oil; 25 aviation kerosene; 20 triphenyl phosphite; 7; bisphenol A56; dibenzoylmethane15.

[0027] The preparation steps are as follows:

[0028] (1) Add oleic acid, isooctanoic acid, benzoic acid, triethylene glycol, p-tert-butylbenzoic acid, and diethylene glycol butyl ether into the reactor, and then stir under the conditions of reactor pressure -0.094Mpa and temperature 70°C uniform.

[0029] (2) Add white oil, solvent oil, D40 oil, and H80 oil to the mixed liquid produced in step 1, place it in a centrifuge barrel at a speed of 2000r / min, and a centrifugal force of 2780Xg for 3 minutes, take it out, and place it in a closed environment at a temperature of 50°C Put it down...

Embodiment 3

[0034] A calcium-zinc liquid stabilizer, consisting of the following raw materials in parts by weight: calcium hydroxide 92; zinc oxide 34; oleic acid 45; isooctanoic acid 19; nonylphenol 20; triethylene glycol 21; benzoic acid 34; 27 base benzoic acid; white oil 19; solvent oil 13; D40 oil 16; H80 oil 12; aviation kerosene 19; triphenyl phosphite 17; 5; bisphenol A51; dibenzoylmethane12.

[0035] The preparation steps are as follows:

[0036] (1) Add oleic acid, isooctanoic acid, benzoic acid, triethylene glycol, p-tert-butylbenzoic acid and diethylene glycol methyl ether into the reactor, and then stir under the conditions of reactor pressure -0.089Mpa and temperature 60°C uniform.

[0037] (2) Add white oil, solvent oil, D40 oil, and H80 oil to the mixed liquid produced in step 1, place it in a centrifuge bucket at a speed of 2000r / min, and a centrifugal force of 2780Xg for 1.5 minutes, take it out, and place it in a closed environment at a temperature of 41°C Put it dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com