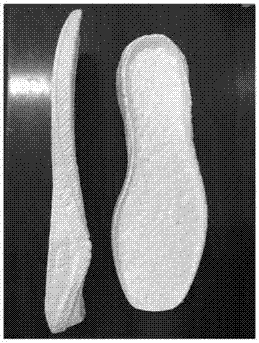

Environment-friendly EVA (ethylene vinyl acetate copolymer) insole

An environmentally friendly, foaming bead technology, applied in shoe soles, footwear, applications, etc., can solve the problems of undisclosed preparation steps and process parameters of supercritical foaming materials, achieve low compression set, increase yield, and be good The effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Formula: 100 parts of EVA, 3 parts of calcium carbonate, 0.5 part of antioxidant 1010, 1 part of antibacterial agent ZnO, 6 parts of titanium dioxide.

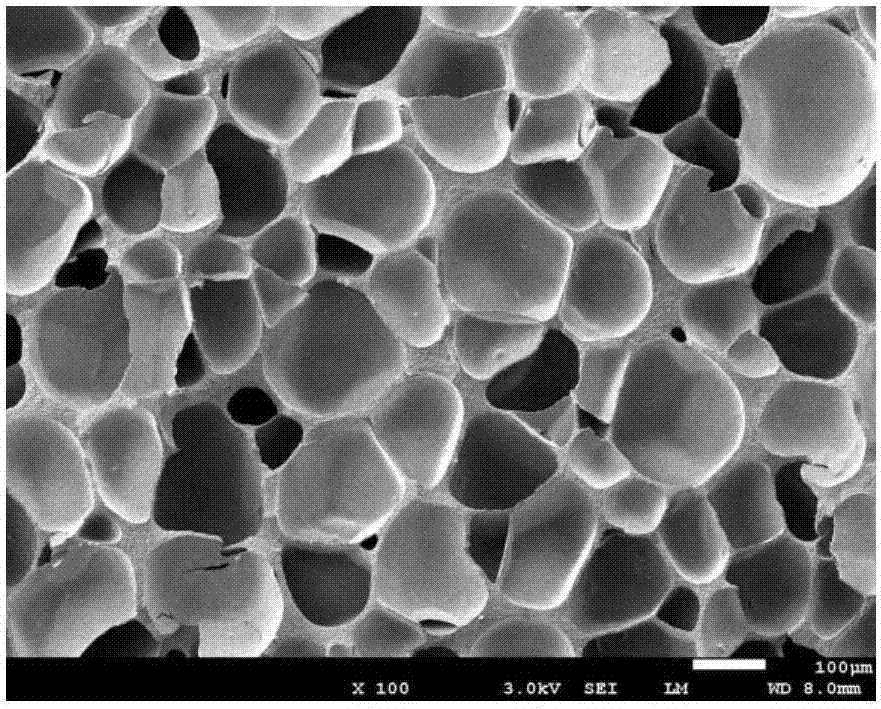

[0024] Preparation steps: Put the raw materials into the internal mixer in turn and knead at 120 ° C. After the kneading is even, discharge, put the film into the extruder, extrude and granulate, and dry; put the above granules into the electron beam Carry out irradiation cross-linking in the irradiator, the irradiation amount is 80kGy; put the irradiation cross-linked particles into the reaction kettle, the temperature in the kettle is 55°C, and the pressure in the kettle reaches 30Mpa after nitrogen gas is introduced, and the sealing is saturated for 16h , and then release the pressure, unload the particles, put them in a 110°C oven for foaming for 10 minutes, and obtain foamed beads; then put the foamed beads into a mold for steam hot-press molding, with a steam pressure of 1.2 MPa, to obtain foamed beads. Foam midso...

Embodiment 2

[0027] Formula: 70 parts of EVA, 30 parts of POE, 1 part of TMPTMA, 5 parts of calcium carbonate, 1 part of antioxidant 1010, 1 part of antibacterial agent ZnO.

[0028] Preparation steps: Put the raw materials into the internal mixer in turn and knead at 115°C. After the kneading is even, discharge, put the film into the extruder, extrude and granulate, and dry; put the above granules into the electron beam Carry out irradiation cross-linking in the irradiator, the irradiation amount is 50kGy; put the irradiation cross-linked particles into the reaction kettle, the temperature in the kettle is 30°C, and the pressure in the kettle reaches 35Mpa after nitrogen gas is introduced, and the sealing is saturated for 8h , and then release the pressure, unload the particles, put them in a 120°C oven for foaming for 12 minutes, and obtain foamed beads; then put the foamed beads into a mold for steam hot-press molding, with a steam pressure of 1.2 MPa, to obtain foamed beads. Foam midso...

Embodiment 3

[0031] 85 parts of EVA, 15 parts of SEBS, 0.2 parts of TMPTMA, 5 parts of calcium carbonate, 1 part of antioxidant 1010, and 1 part of antibacterial agent ZnO.

[0032] Preparation steps: Put the raw materials into the internal mixer in turn and knead at 115°C. After the kneading is even, discharge, put the film into the extruder, extrude and granulate, and dry; put the above granules into the electron beam Carry out irradiation cross-linking in the radiation, the irradiation dose is 60kGy; put the irradiation cross-linked particles into the reaction kettle, the temperature in the kettle is 70°C, after feeding nitrogen gas, the pressure inside the kettle reaches 30Mpa, seal and saturate for 8h, Then release the pressure, unload the particles, put them into a 120°C oven for foaming, and obtain foamed beads; then put the foamed beads into a mold for steam hot-press molding, with a steam pressure of 1.2 MPa, to obtain foamed shoes midsole.

[0033] Basic properties: density is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com