An Organic Rankine Cycle Waste Heat Power Generation System Based on Falling Film Evaporator

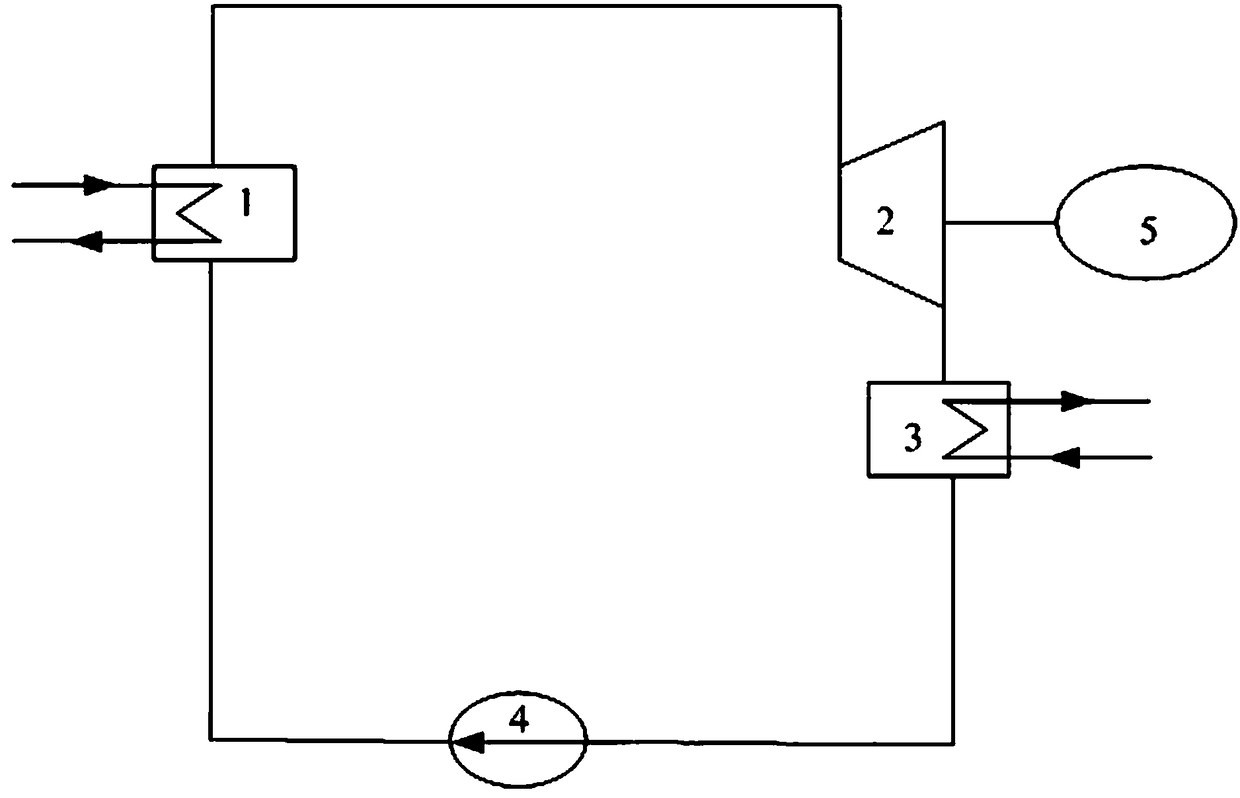

A falling film evaporator and falling film evaporation technology are applied in the direction of steam engine devices, machines/engines, steam generation methods using heat carriers, etc., which can solve the problem of low heat exchange efficiency of falling film evaporation tubes, affecting the uniformity of liquid film thickness, Inability to make full use of heat sources and other issues to achieve the effects of improving energy utilization, high thermoelectric conversion efficiency, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

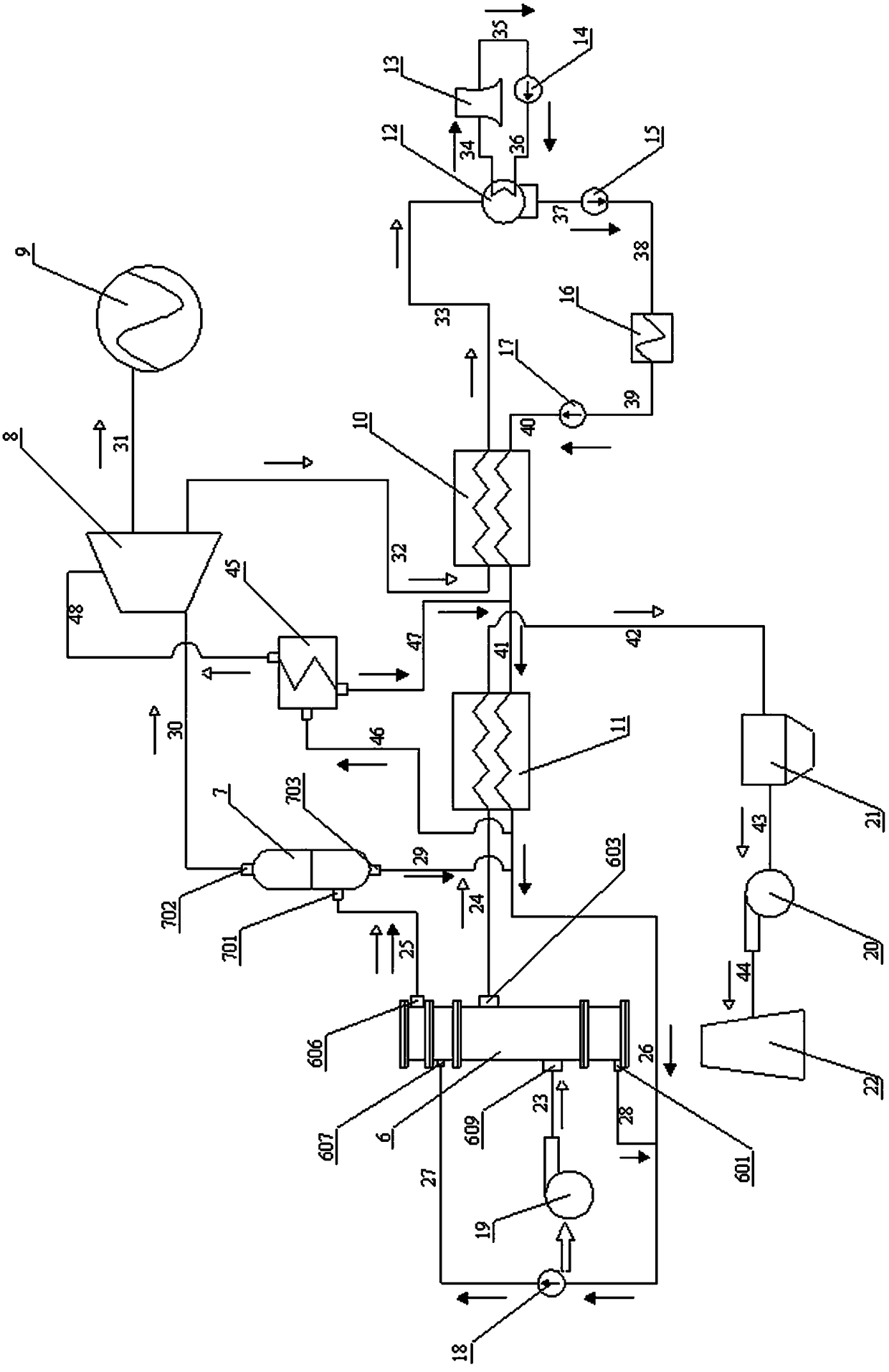

[0021] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

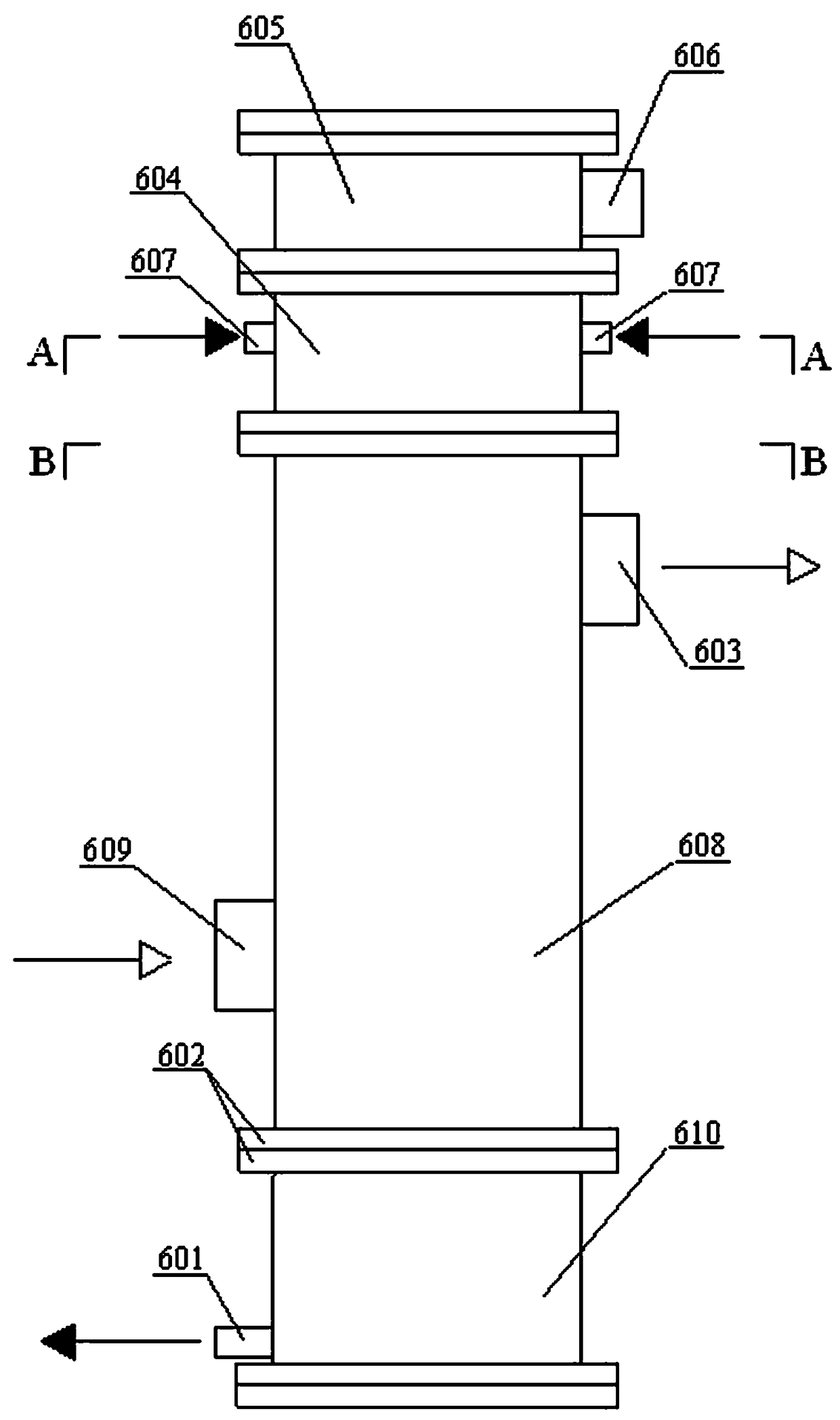

[0022] Such as Figure 3 ~ Figure 6As shown, the present invention provides an organic Rankine cycle waste heat power generation system based on a falling film evaporator, comprising a falling film evaporator 6, an upper cover 605 coaxially fixedly connected sequentially from top to bottom, a working fluid storage and distribution device 604, the evaporator body 608 and the liquid collector 610, the lower end of the evaporator body 608 is provided with a first sealing baffle, and the upper end of the evaporator body 608 is provided with a second sealing baffle to form a falling film evaporation chamber 614 , the upper end of the falling film evaporation chamber 614 is provided with a waste heat flue gas outlet 603, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com