Method of extracting and separating nano-scale precipitates in steel by means of organic electrolyte

A technology of organic electrolyte and precipitates, which is applied in the field of metal electrochemistry, can solve the problems of easy agglomeration of precipitates, and achieve the effect of solving easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

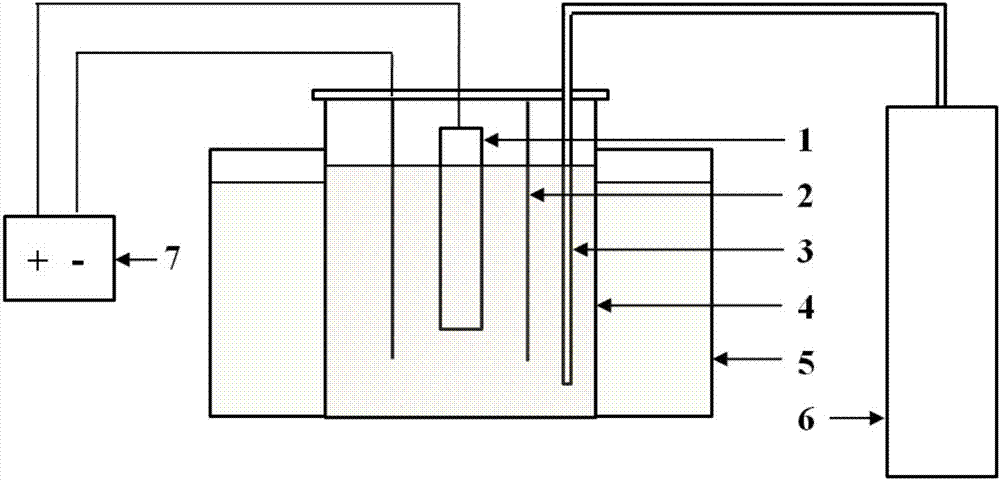

[0027] (1) Step A of the method provided by the present invention for extracting and separating nanoscale precipitates in steel using organic electrolyte can be as follows: figure 1 The device shown is implemented. like figure 1 As shown, the electrolytic cell 4 is located in the low-temperature constant temperature tank 5, and the organic electrolyte is put into the electrolytic cell 4; one end of the air pipe 3 extends into the bottom of the organic electrolyte, and the other end communicates with the inert gas bottle 6; to be extracted Both the steel material 1 and the stainless steel cylinder 2 are placed in the organic electrolyte, and the steel material 1 to be extracted is located on the axis line of the stainless steel cylinder 2, the steel material 1 to be extracted is electrically connected to the anode of the constant voltage power supply 7, and the stainless steel cylinder 2 is connected to the anode of the constant voltage power supply 7. The cathode of the const...

Embodiment 1

[0040] A method for extracting and separating nanoscale precipitates in steel using an organic electrolyte, comprising the steps of:

[0041] Step a1, process the steel to be extracted into a cuboid of 22mm, 6mm in width and 100mm in height, and drill a round hole with a diameter of 4mm at one end of the steel to be extracted, so as to facilitate the lifting of the steel to be extracted Hanging electrolysis; the surface of the steel to be extracted is processed to a smoothness of ▽6, and ultrasonic cleaning is performed with absolute ethanol, so as to obtain smooth and clean steel to be extracted.

[0042] Step b1, using such as figure 1 The shown device carries out constant voltage electrolysis; the organic electrolytic solution is put into the electrolytic cell 4, and the organic electrolytic solution is composed of 1.5wt.% tetramethylammonium chloride, 10wt.% acetylacetone and the balance of anhydrous Composed of methanol; the steel to be extracted and the stainless steel ...

Embodiment 2

[0047] A method for extracting and separating nanoscale precipitates in steel using an organic electrolyte, comprising the steps of:

[0048] Step a2, process the steel to be extracted into a cuboid of 25mm, 8mm in width, and 110mm in height, and drill a round hole with a diameter of 4mm at one end of the steel to be extracted, so as to facilitate the lifting of the steel to be extracted Hanging electrolysis; the surface of the steel to be extracted is processed to a smoothness of ▽6, and ultrasonic cleaning is performed with absolute ethanol, so as to obtain smooth and clean steel to be extracted.

[0049] Step b2, using such as figure 1 The shown device carries out constant voltage electrolysis; the organic electrolytic solution is put into the electrolytic cell 4, and the organic electrolytic solution is composed of 1wt.% tetramethylammonium chloride, 10wt.% acetylacetone and the anhydrous methanol of the balance Composition; the steel to be extracted and the stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com