Graphene battery negative electrode composite material

A battery negative electrode and composite material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory dispersion effect, affecting the electrical properties of graphene, poor stability of graphene, etc., to achieve high capacity and cycle stability, Improve electrical performance, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

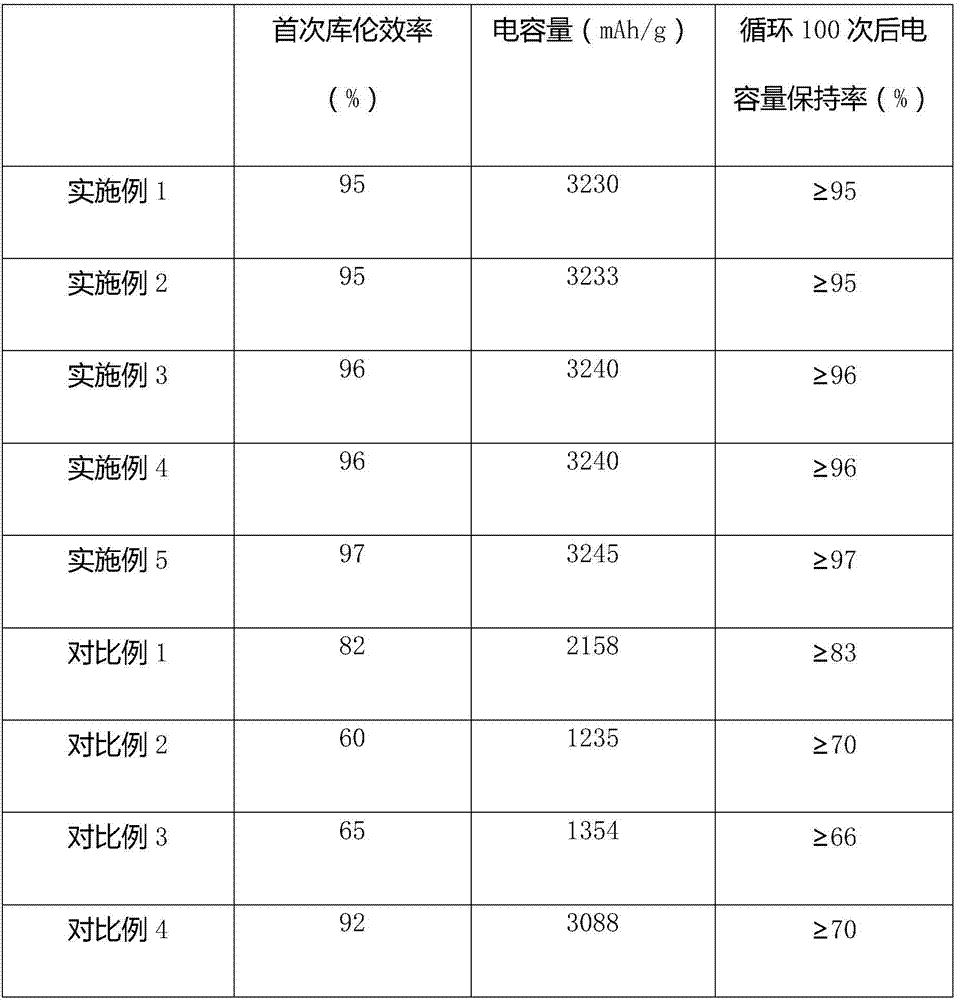

Examples

Embodiment 1

[0028] A graphene battery negative electrode composite material is obtained by sequentially coating carbon and silicon carbide on the surface of graphene, wherein the mass ratio of graphene, carbon and silicon carbide is 1:0.08:0.15.

[0029] The preparation method of above-mentioned a kind of graphene battery negative electrode composite material, concrete steps are as follows:

[0030] (1) Dispersed graphene: graphene is uniformly dispersed in ethylene glycol under the action of polyoxyethylene castor oil;

[0031] (2) Coated carbon: Add the dispersed graphene obtained in step (1) into the organic carbon source aqueous solution, stir for 3 hours, continue stirring at 110°C to evaporate the solvent, and then pyrolyze at 800°C for 5 hours to obtain the carbon coated covered graphene;

[0032] (3) Coated silicon carbide: place silicon carbide and carbon-coated graphene obtained in step (1) together in a ball mill for grinding, place the obtained powder in a tube furnace for he...

Embodiment 2

[0041] A graphene battery negative electrode composite material is obtained by sequentially coating carbon and silicon carbide on the surface of graphene, wherein the mass ratio of graphene, carbon and silicon carbide is 1:0.1:0.25.

[0042] The preparation method of above-mentioned a kind of graphene battery negative electrode composite material, concrete steps are as follows:

[0043] (1) Dispersed graphene: graphene is uniformly dispersed in ethylene glycol under the action of polyoxyethylene castor oil;

[0044] (2) Coated carbon: Add the dispersed graphene obtained in step (1) into the organic carbon source aqueous solution, stir for 4 hours, continue stirring at 120°C to evaporate the solvent, and then pyrolyze it at 1000°C for 8 hours to obtain the carbon coated covered graphene;

[0045] (3) Coated silicon carbide: place silicon carbide and carbon-coated graphene obtained in step (1) together in a ball mill for grinding, place the obtained powder in a tube furnace for...

Embodiment 3

[0054] A graphene battery negative electrode composite material is obtained by sequentially coating carbon and silicon carbide on the surface of graphene, wherein the mass ratio of graphene, carbon and silicon carbide is 1:0.08:0.25.

[0055] The preparation method of above-mentioned a kind of graphene battery negative electrode composite material, concrete steps are as follows:

[0056] (1) Dispersed graphene: graphene is uniformly dispersed in ethylene glycol under the action of polyoxyethylene castor oil;

[0057] (2) Coated carbon: Add the dispersed graphene obtained in step (1) into the organic carbon source aqueous solution, stir for 3 hours, continue stirring at 120°C to evaporate the solvent, and then pyrolyze it at 800°C for 8 hours to obtain the carbon coated covered graphene;

[0058] (3) Coated silicon carbide: place silicon carbide and carbon-coated graphene obtained in step (1) together in a ball mill for grinding, place the obtained powder in a tube furnace for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com