Single-stage photovoltaic grid-connected micro inverter and control method thereof

A micro-inverter, single-stage technology, applied in the electrical field, can solve the problems of difficulty in increasing the power, increase the volume of the inverter, burn out the circuit, etc., and achieve the effect of reducing the voltage distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

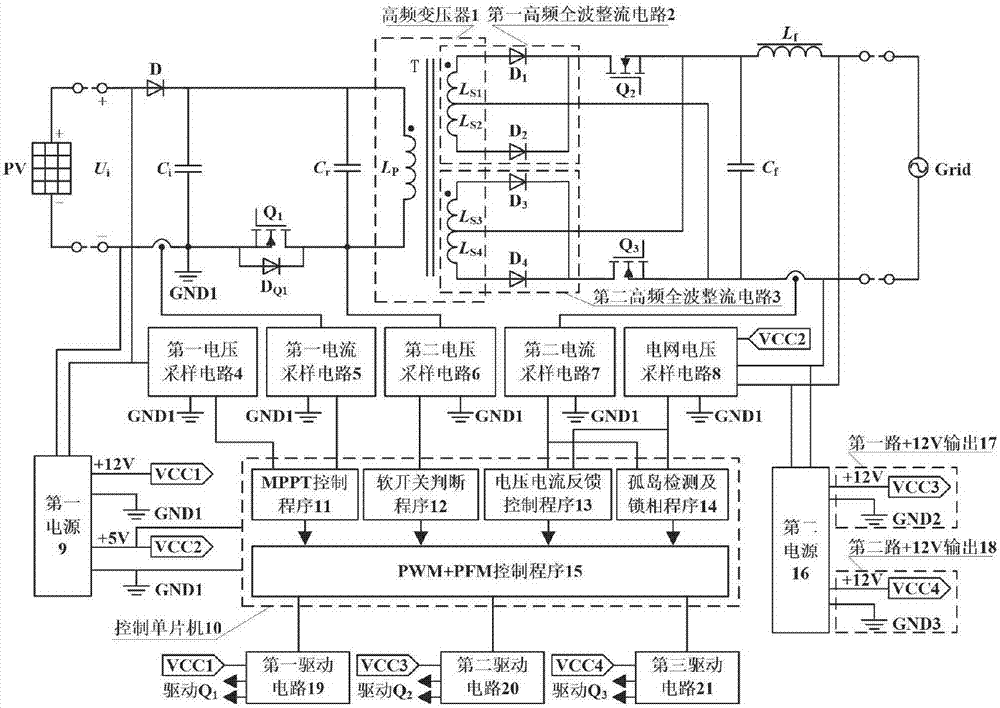

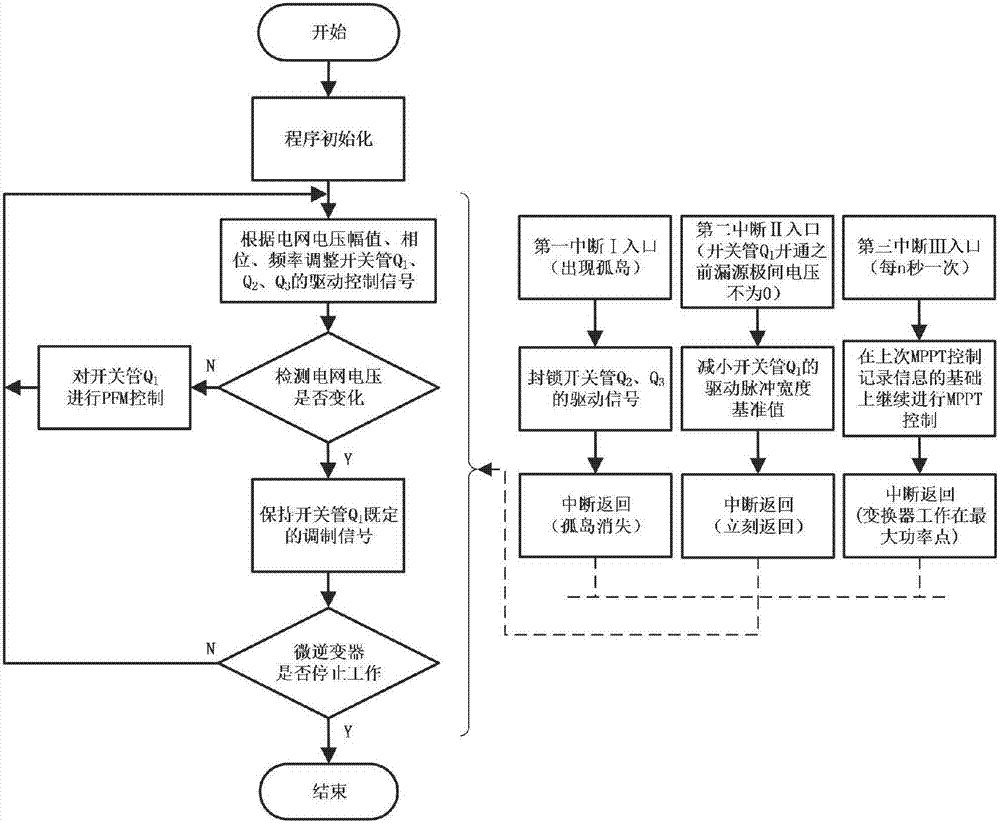

[0021] The main structure of the single-stage photovoltaic grid-connected micro-inverter in this embodiment includes a reverse blocking diode D, a capacitor C i , Resonant capacitance C r , the first switching tube Q 1 , Freewheeling diode D Q1 , high-frequency transformer 1, first high-frequency full-wave rectifier circuit 2, second high-frequency full-wave rectifier circuit 3, second switching tube Q 2 , the third switching tube Q 3 , filter capacitor C f , filter inductance L f , the first voltage sampling circuit 4, the first current sampling circuit 5, the second voltage sampling circuit 6, the second current sampling circuit 7, the grid voltage sampling circuit 8, the first power supply 9, the second power supply 16, the control microcontroller 10, the second A driving circuit 19, a second driving circuit 20 and a third driving circuit 21; the input voltage U i through the reverse blocking diode D and by the capacitor C i After filtering, it is used as the input o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com