High-flexibility leakage-resistant waterproof mortar

An anti-seepage and waterproof, high-flexibility technology, applied in the field of building materials, can solve the problems of polluted water sources, serious hazards, waste of land and resources, etc., and achieve the effects of protecting the environment, improving impermeability, and avoiding the occupation of cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

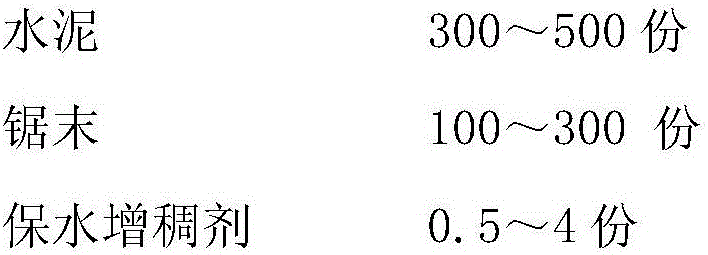

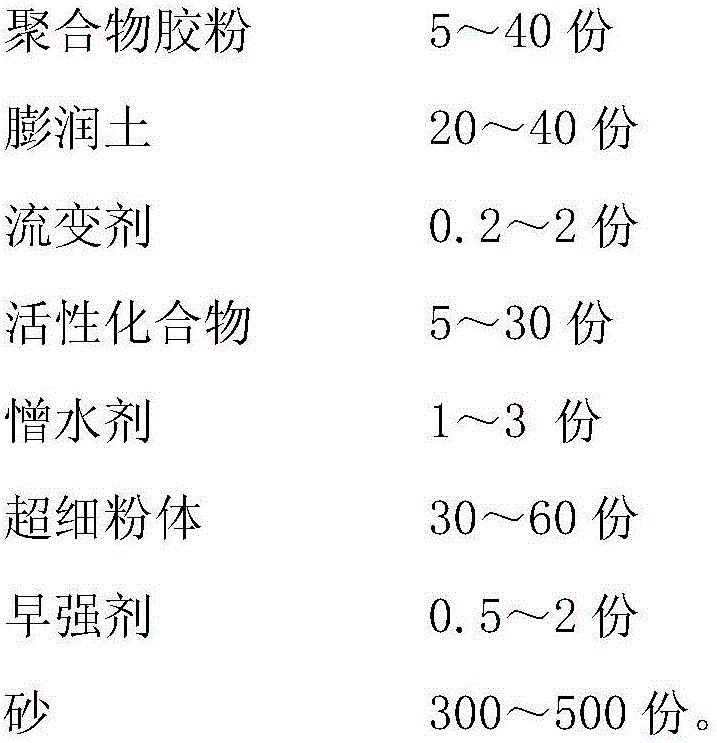

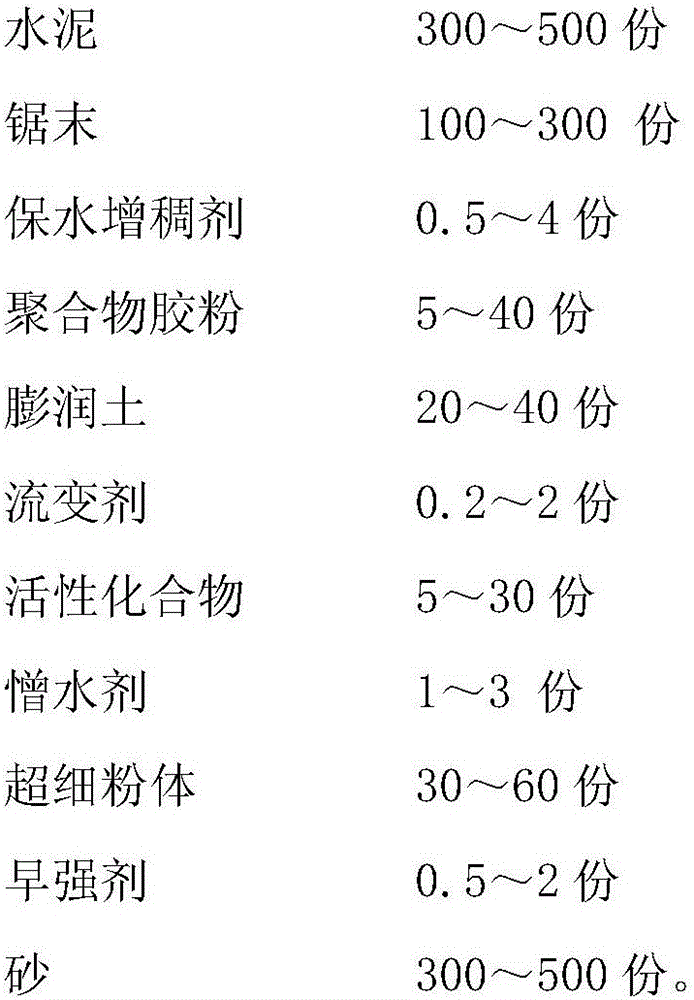

[0028] A preparation method of highly flexible anti-seepage and waterproof mortar, which is composed of: 500 parts of cement, 300 parts of sawdust, 4 parts of water-retaining thickener, 30 parts of polymer rubber powder, 30 parts of bentonite, and rheological agent: 2 parts, active compound: 30 parts, water-repellent agent: 2 parts; superfine powder: 30 parts, early strength agent: 2 parts, sand: 300 parts.

[0029] Wherein the cement is aluminate cement; the water-retaining thickener is hydroxyethyl methyl cellulose ether; the polymer rubber powder is latex powder copolymerized with vinyl acetate and ethylene, with a solid content of ≥98%, fine Degree of 0.5 ~ 8μm; the bentonite moisture 10; the rheological agent is a mixture of naphthalene water reducer and sodium lignin sulfonate, the mass ratio is 7:3; the active compound is Silicone zirconium; the water-repellent agent is calcium stearate water-repellent agent; the superfine powder is a mixture of silica fume and mineral...

Embodiment 2

[0033] A method for preparing highly flexible anti-seepage and waterproof mortar, which is composed of: 450 parts of cement, 100 parts of sawdust, 2 parts of water-retaining thickener, 40 parts of polymer rubber powder, 20 parts of bentonite, and rheological agent: 2 parts, active compound: 5 parts, water-repellent agent: 3 parts; superfine powder: 60 parts, early strength agent: 1 part, sand: 500 parts.

[0034] Wherein the cement is aluminate cement; the water-retaining thickener is methyl cellulose ether; the polymer rubber powder is latex powder copolymerized with vinyl acetate and ethylene, with a solid content of ≥98% and a fineness of 0.5- 8 μm; the moisture content of the bentonite is less than 10%, and the 24h expansion ratio is greater than 10; the rheological agent is a mixture of naphthalene-based water reducer and calcium sodium lignosulfonate, and the mass ratio is 7:3; the active compound is silicone Zirconium; the water-repellent agent is a modified water-repel...

Embodiment 3

[0038] A preparation method of highly flexible anti-seepage waterproof mortar, which is composed of: 300 parts of cement, 150 parts of sawdust, 0.5 parts of water-retaining thickener, 5 parts of polymer rubber powder, 40 parts of bentonite, and rheological agent: 0.2 parts, active compound: 15 parts, water-repellent agent: 3 parts; superfine powder: 50 parts, early strength agent: 2 parts, sand: 440 parts.

[0039] Wherein the cement is sulfoaluminate cement; the water-retaining thickener is hydroxyethyl cellulose ether; the polymer rubber powder is latex powder copolymerized with vinyl acetate and ethylene, with a solid content of ≥98%, fineness 0.5-8μm; the moisture content of the bentonite is 10; the rheology agent is a mixture of naphthalene-based water reducer, sodium lignosulfonate, and calcium lignosulfonate, with a mass ratio of 3:1 : 1; the active compound is silicone zirconium; the water-repellent is a silicone water-repellent; the superfine powder is a mixture of si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Impermeability pressure | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com