Preparation method of solvent-free block silicone oil

A block silicone oil, solvent-free technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of reducing the wet rubbing color fastness and dry rubbing color fastness of fabrics, safely burying hidden dangers, polluting the environment, etc. Wet rubbing fastness and dry rubbing fastness, environmental protection, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of solvent-free block silicone oil, comprising the following steps:

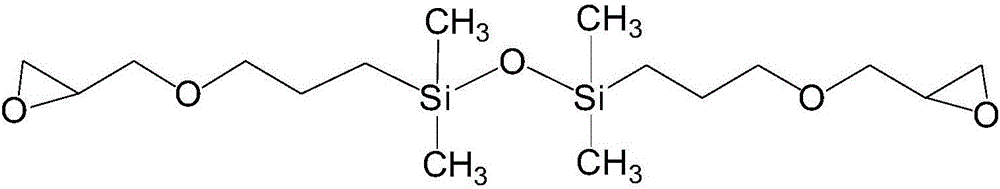

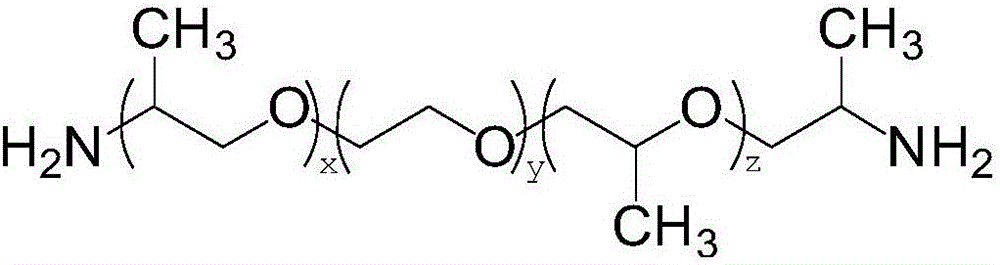

[0034] Step S1, 1,3-bis(3-glycidylpropyl)-1,1,3,3-tetramethyldisiloxane (referred to as epoxy bissiloxane) with a molar ratio of 1:(1-1.8) Head) and polyetheramine are sequentially added into the reaction flask, the reaction temperature is controlled at 90-110° C., and the ring-opened hydroxyl-containing polyamine coupling agent intermediate is obtained after reacting for 4-12 hours.

[0035] Its chemical reaction equation is:

[0036]

[0037] where PO is: EO is:—CH 2 CHO; x, y, z≥1.

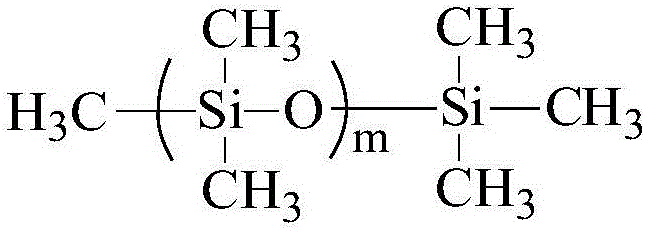

[0038] Step S2, add the dimethylcyclosiloxane mixture and the hydroxyl-containing polyamine coupling agent intermediate obtained in step S1 into the reaction flask in turn, stir and heat up, add a basic catalyst at 50-90°C, and continue to heat up to 90-110°C, keep warm for 4-12 hours, then continue to heat up to 140-150°C for vacuum distillation to remove low boilers and catalysts to obtai...

Embodiment 8

[0045] Example 8, a method for preparing a solvent-free block silicone oil, differs from Example 1 in that: the basic catalyst is potassium hydroxide KOH.

Embodiment 9

[0046] Example 9, a method for preparing a solvent-free block silicone oil, differs from Example 1 in that: the basic catalyst is sodium hydroxide NaOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com