Preparation method of synthetic material auxiliary fluid for switch processing

A technology for synthesizing materials and auxiliary liquids, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc., can solve the problems of raw material quality damage, destruction of synthetic materials, etc. The effect of improving combustion performance and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

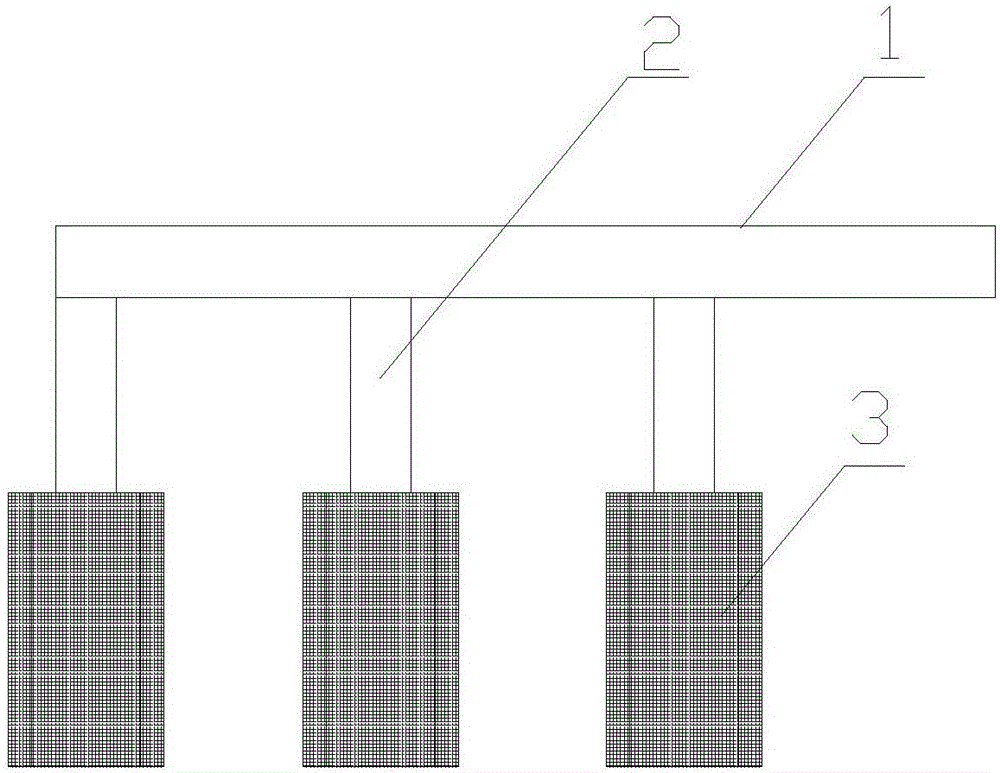

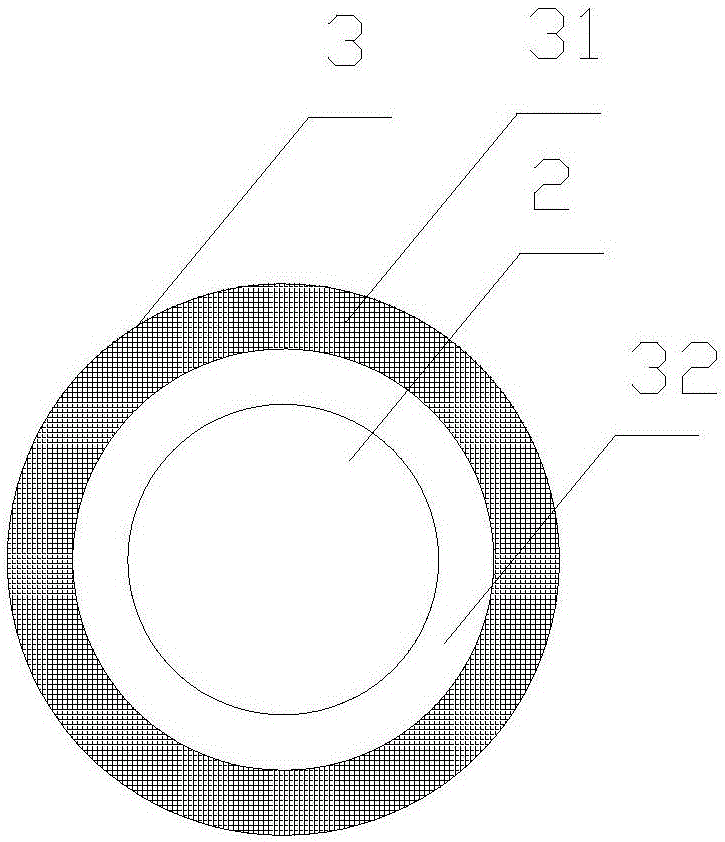

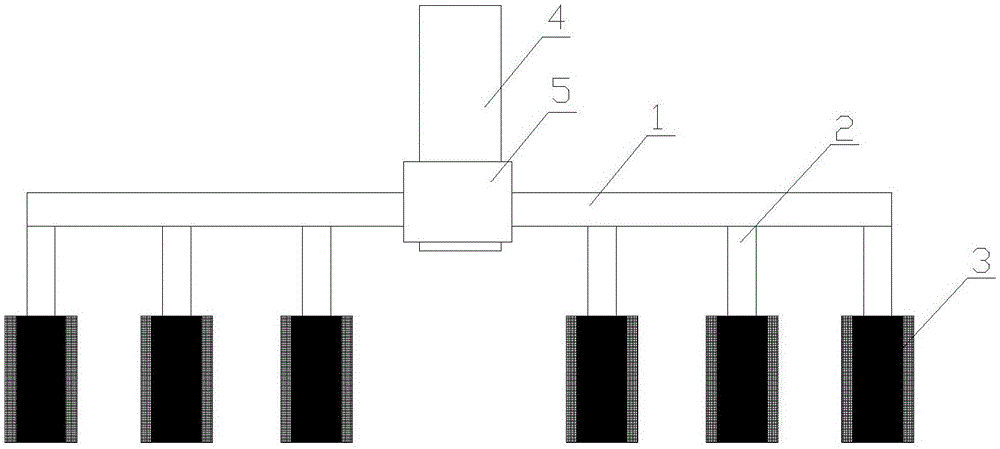

Image

Examples

Embodiment 1

[0039] A method for preparing a synthetic material auxiliary liquid method for switch processing, the specific steps are as follows:

[0040] (1) First add hydrogen peroxide and calamine lotion into the mixer, set the temperature of the mixer to 85°C, and mix for 40 minutes to fully mix the two materials to make a mixed solution;

[0041] (2) Send the mixed solution into a centrifugal mixer for centrifugal stirring, stir it for 2 hours, put it into an iron pot until the temperature rises to 80°C, and keep it at a constant temperature for 2 hours;

[0042] (3) Then add fluorite powder, synergist, nucleating agent, lubricant, antioxidant, and initiator to the mixer in turn for stirring. When stirring, use a uniform stirring method, and the stirring speed is set to: 600 rpm / minute;

[0043] (4) Then pour out the mixing material, put it into the internal mixer for internal mixing, set the temperature of the internal mixer to 90°C, stop the internal mixing after 70 minutes, and mix...

Embodiment 2

[0053] A method for preparing a synthetic material auxiliary liquid method for switch processing, the specific steps are as follows:

[0054] (1) First add hydrogen peroxide and calamine lotion into the mixer, set the temperature of the mixer to 95°C, and mix for 25 minutes to fully mix the two materials to make a mixed solution;

[0055] (2) Send the mixed solution into a centrifugal mixer for centrifugal stirring, stir for 3 hours, put it into an iron pot until the temperature rises to 85°C, and then keep it at a constant temperature for 1 hour;

[0056] (3) Then add fluorite powder, synergist, nucleating agent, lubricant, antioxidant, and initiator to the mixer in turn for stirring. When stirring, use a uniform stirring method, and the stirring speed is set to: 600 rpm / minute;

[0057] (4) Then pour out the mixing material, put it into the internal mixer for internal mixing, set the temperature of the internal mixer to 90°C, stop the internal mixing after 50 minutes, and ...

Embodiment 3

[0067] A method for preparing a synthetic material auxiliary liquid method for switch processing, the specific steps are as follows:

[0068] (1) First add hydrogen peroxide and calamine lotion into the mixer, set the temperature of the mixer to 90°C, and mix for 30 minutes to fully mix the two materials to make a mixed solution;

[0069] (2) Send the mixed solution into a centrifugal mixer for centrifugal stirring, stir it for 2.5 hours, put it into an iron pot until the temperature rises to 83°C, and keep it at a constant temperature for 1.5 hours;

[0070] (3) Then add fluorite powder, synergist, nucleating agent, lubricant, antioxidant, and initiator to the mixer in turn for stirring. When stirring, use a uniform stirring method, and the stirring speed is set to: 600 rpm / minute;

[0071] (4) Then pour out the mixing material, put it into the internal mixer for internal mixing, set the temperature of the internal mixer to 85°C, stop the internal mixing after 60 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com