High-yield halogen perovskite/silica microsphere composite phosphor one-step synthesis method

A technology of silicon dioxide and synthesis methods, applied in chemical instruments and methods, organic chemistry, luminescent materials, etc., can solve the problems of low color rendering index of devices, incomplete excitation, and difficult to control the size of phosphor particles, and achieve luminescent performance. Excellent, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A one-step synthesis method for high-yield halogen perovskite / silica microsphere composite phosphors, including the following steps: aminated silica microspheres, lead halide or tin halide, cesium carbonate or methylamine bromide or acetic acid Put formamidine and octadecene into a flask, add surfactant to it, the surfactant is oleic acid or a mixture of oleylamine and oleic acid in the same volume, at 150-300°C, the speed is 1200r / min, stir for 5 -10 minutes, then cool in an ice water bath for 30s.

[0014] The amount ratio of aminated silica microspheres, lead halide or tin halide, cesium carbonate or methylamine bromide or formamidine acetate, octadecene and surfactant is: 0.3g: 0.11g: 0.02-0.03g: 10-15ml: 1-1.4ml.

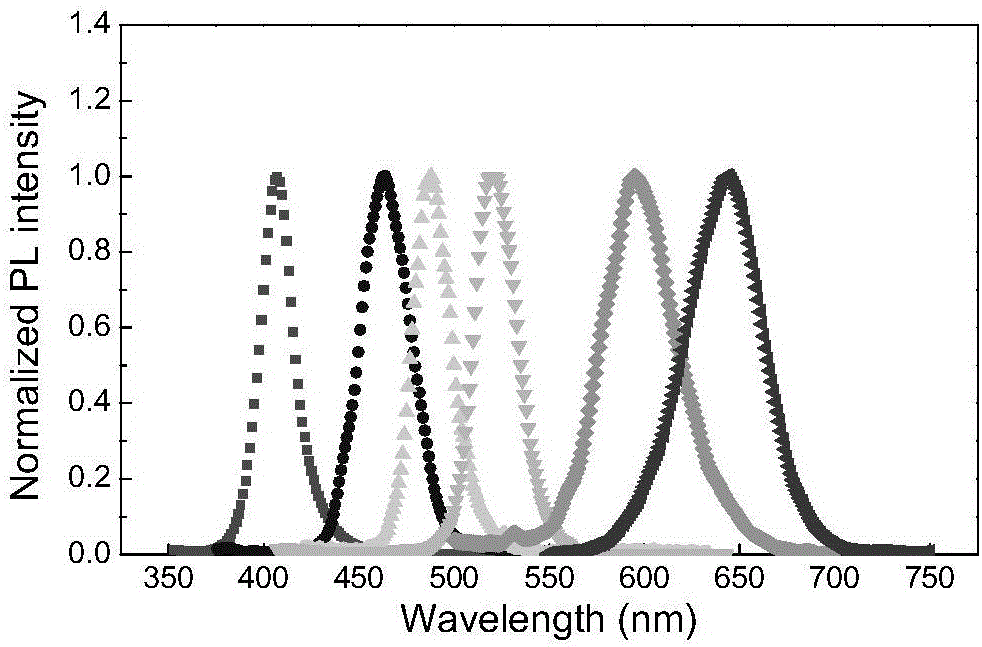

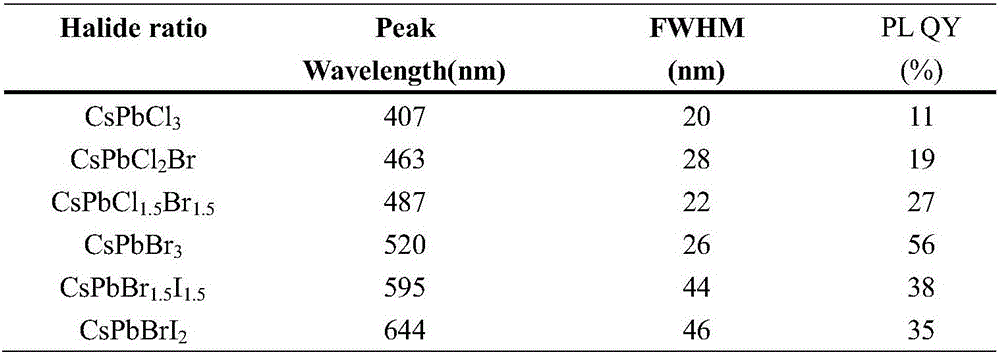

Embodiment 1

[0016] Weigh 0.0326g of cesium carbonate, 0.3g of aminated silica microspheres, 0.0834g of lead chloride, measure 15ml of octadecene, 0.5ml of oleylamine, and 0.5ml of oleic acid. The above raw materials were mixed and put into a flask, vigorously stirred and reacted at 200 degrees Celsius at a speed of 1200 r / min for 5 minutes, and then cooled with an ice-water bath for 30 seconds. The maximum luminous wavelength of the prepared composite fluorescent powder is 407nm, the full width at half maximum is 20nm, and the fluorescent quantum efficiency is 11%.

Embodiment 2

[0018] Weigh 0.0326g of cesium carbonate, 0.3g of aminated silica microspheres, 0.0417g of lead chloride, 0.055g of lead bromide, measure 15ml of octadecene, 0.5ml of oleylamine, and 0.5ml of oleic acid. The above raw materials were mixed and put into a flask, vigorously stirred and reacted at 200 degrees Celsius at a speed of 1200 r / min for 5 minutes, and then cooled with an ice-water bath for 30 seconds. The maximum luminous wavelength of the prepared composite fluorescent powder is 463nm, the full width at half maximum is 28nm, and the fluorescent quantum efficiency is 19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com