An Online Robust Soft Sensing Method for Blast Furnace Hot Metal Quality

A blast furnace hot metal and soft sensor technology, applied in the direction of neural learning methods, instruments, biological neural network models, etc., can solve the problem of solving hidden layer output matrix time and increasing computational complexity, can not inhibit the prediction of molten iron quality parameters, and increase equipment costs and labor costs, etc., to avoid time and calculation troubles, save labor costs, and have good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

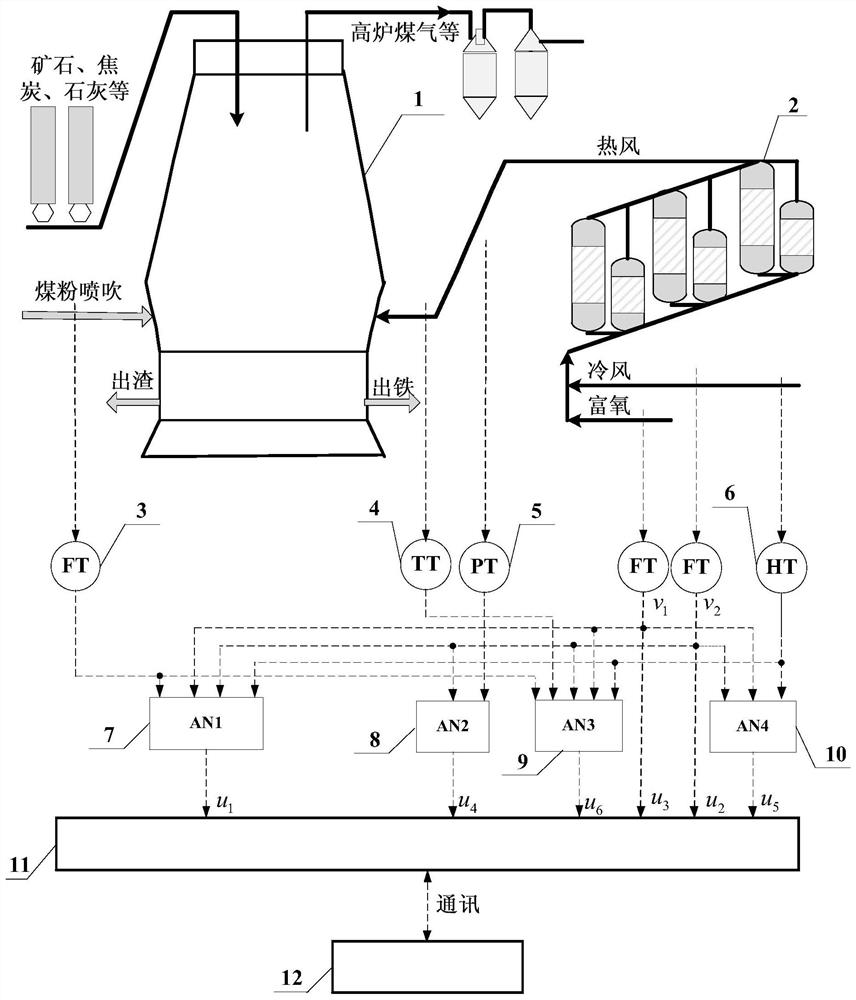

[0043] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] Take a volume of Liuzhou Steel as 2600m 3 Taking the iron-making blast furnace object as an example, the online robust soft-sensing method for blast furnace molten iron quality of the present invention is applied. The current iron-making blast furnace object is installed with the following conventional measurement systems, including: pressure transmitters for measuring the hot blast pressure of the blast furnace hot blast system, differential pressure flowmeters for measuring the flow of cold air, balances for measuring the flow of enriched oxygen Flow meter, air humidity sensor to measure blast humidity, infrared thermometer to measure hot air temperature, pulverized coal flow meter to measure pulverized coal injection volume, and:

[0045] Bosh gas volume measurement analyzer: analyze and calculate the bosh gas volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com