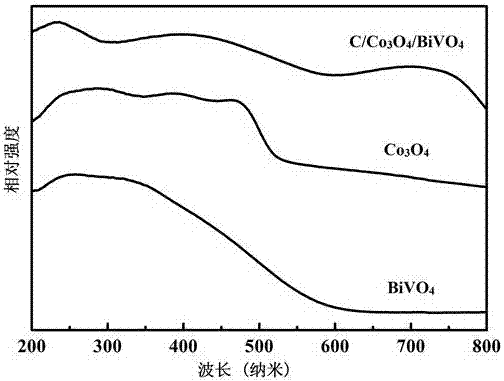

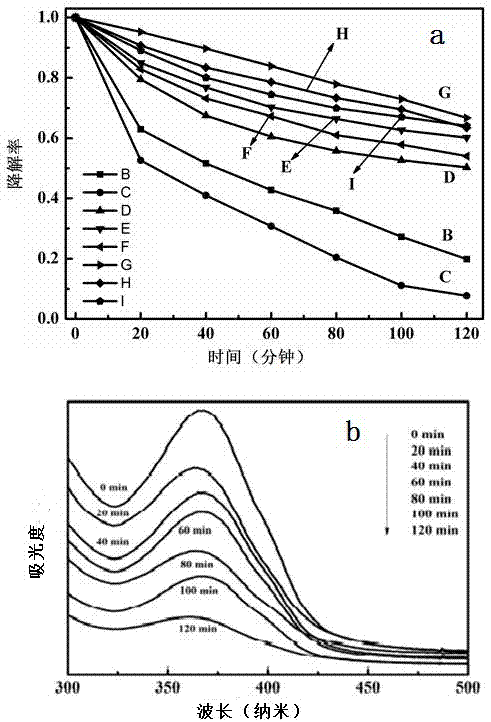

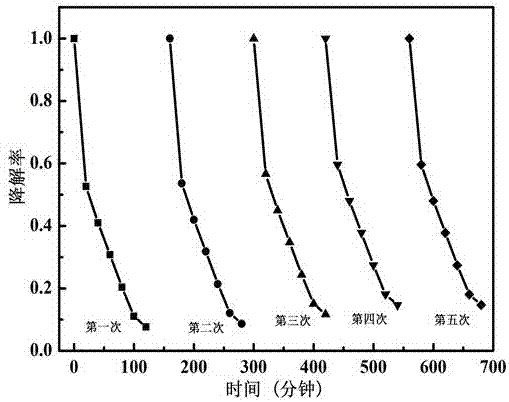

C/Co3O4/BiVO4 composite photo catalyst and preparation method and application thereof

A catalyst and composite light technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of easy loss, fine particles, difficult recycling, etc. Ease of recycling, good photochemical stability and magnetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Nano Co 3 o 4 preparation of

[0027] 0.4mL ammonium solution (NH 3 ·H 2 O, 25%) was added to 25 mL of 1 mM cobalt acetate aqueous solution, followed by stirring for 15 minutes. The solution was then transferred to a 50 mL Teflon-lined stainless steel autoclave. The hydrothermal synthesis was performed at 150ºC for 3 hours. After the stainless steel autoclave was cooled to room temperature with running water, the obtained product was centrifuged, washed with ion-exchanged water and ethanol three times respectively, and finally, the obtained sample was dried in a drying oven at 80 ºC.

[0028] (2) Co. 3 o 4 / BiVO 4 preparation of

[0029] co 3 o 4 / BiVO 4 The material was prepared by EDTA-assisted hydrothermal method. In a typical synthesis, 10 mmol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 2M nitric acid to obtain solution A; meanwhile, 10 mmol of NH 4 VO 3 Dissolve in 2M sodium hydroxide solution, then add 2g of EDTA to form solution B; solution B...

Embodiment 2

[0033] (1) Nano Co 3 o 4 preparation of

[0034] 0.4mL ammonium solution (NH 3 ·H 2 O, 25% by weight) was added to 25 mL of 1 mM cobalt acetate aqueous solution, followed by stirring for 15 minutes. The solution was then transferred to a 50 mL Teflon-lined stainless steel autoclave. The hydrothermal synthesis was performed at 150ºC for 3 hours. After the stainless steel autoclave was cooled to room temperature with running water, the obtained product was centrifuged, washed with ion-exchanged water and ethanol three times respectively, and finally, the obtained sample was dried in a drying oven at 80 ºC.

[0035] (2) Co. 3 o 4 / BiVO 4 preparation of

[0036] co 3 o 4 / BiVO 4 The material was prepared by EDTA-assisted hydrothermal method. In a typical synthesis, 10 mmol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 2M nitric acid to obtain solution A. At the same time, 10 mmol of NH 4 VO 3 Dissolve in 2M sodium hydroxide solution, then add 2g of EDTA to form solu...

Embodiment 3

[0040] (1) Nano Co 3 o 4 preparation of

[0041] 0.4mL ammonium solution (NH 3 ·H 2 O, 25% by weight) was added to 25 mL of 1 mM cobalt acetate aqueous solution, followed by stirring for 15 minutes. The solution was then transferred to a 50 mL Teflon-lined stainless steel autoclave. The hydrothermal synthesis was performed at 150ºC for 3 hours. After the stainless steel autoclave was cooled to room temperature with running water, the obtained product was centrifuged, washed with ion-exchanged water and ethanol three times respectively, and finally, the obtained sample was dried in a drying oven at 80 ºC.

[0042] (2) Co. 3 o 4 / BiVO 4 preparation of

[0043] co 3 o 4 / BiVO 4 The material was prepared by EDTA-assisted hydrothermal method. In a typical synthesis, 10 mmol of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 2M nitric acid to obtain solution A; meanwhile, 10 mmol of NH 4 VO 3 Dissolve in 2M sodium hydroxide solution, then add 2g of EDTA to form solution B; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com