Reinforced polypropylene plastic glass fiber soakage agent

A polypropylene plastic and glass fiber technology, applied in the field of reinforced polypropylene plastic glass fiber sizing agent, can solve the problems of fiber breakage and insufficient clustering, and achieve enhanced plasticity and stiffness, improved mechanical properties, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

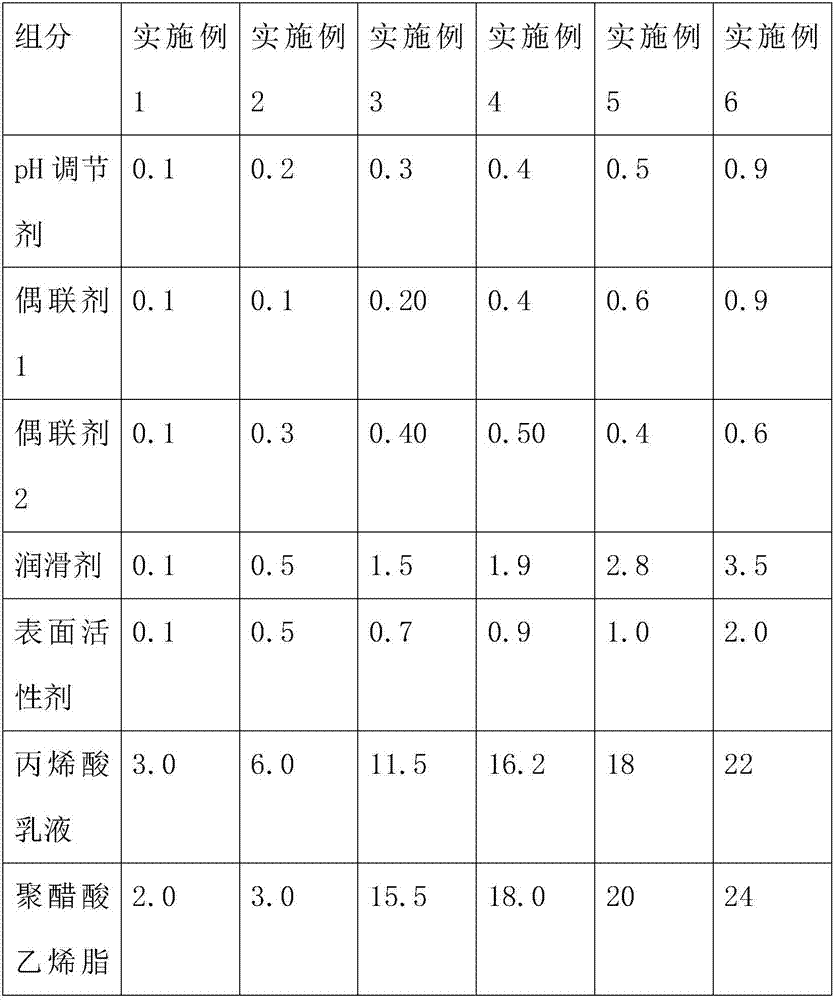

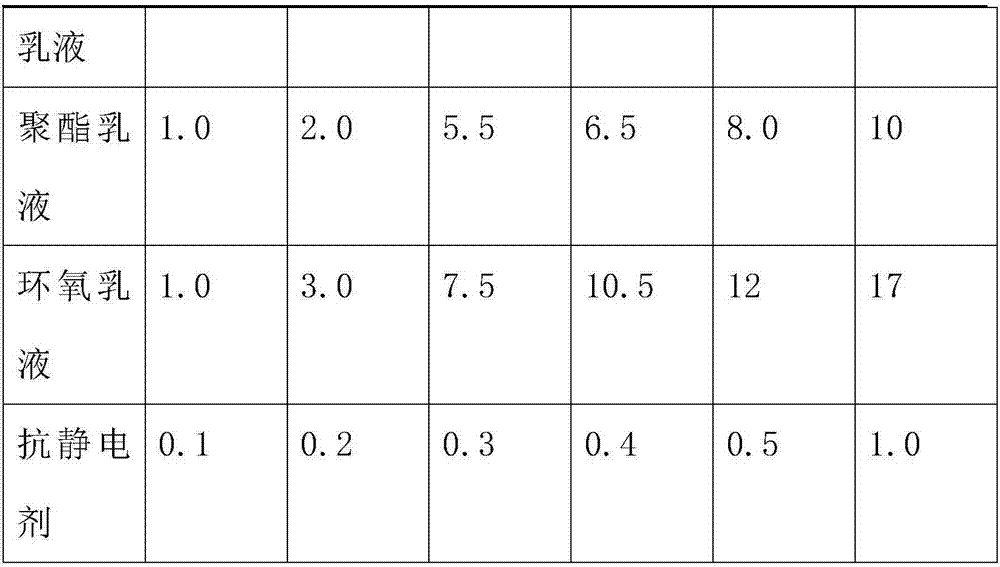

[0017] See Table 1, coupling agent 1 is γ-(methacryloyloxy)propyltrimethoxysilane, model is KH570, and coupling agent 2 is γ-aminopropyltriethoxysilane, model is KH550; The pH regulator is industrial grade glacial acetic acid, purchased from Jining Xuli Chemical Co., Ltd.; the lubricant is collected from Italy DSM, model Neoxil LC 19710; the polyurethane emulsion is collected from Italy COIM, model FILCO 322; the epoxy emulsion is collected from Italy COIM , Model FILCO362.

[0018] The specific wetting agent formula is shown in the following table (where the data in the table is the percentage of the mass of the components in the total mass of the wetting agent): Table 1

[0019]

[0020]

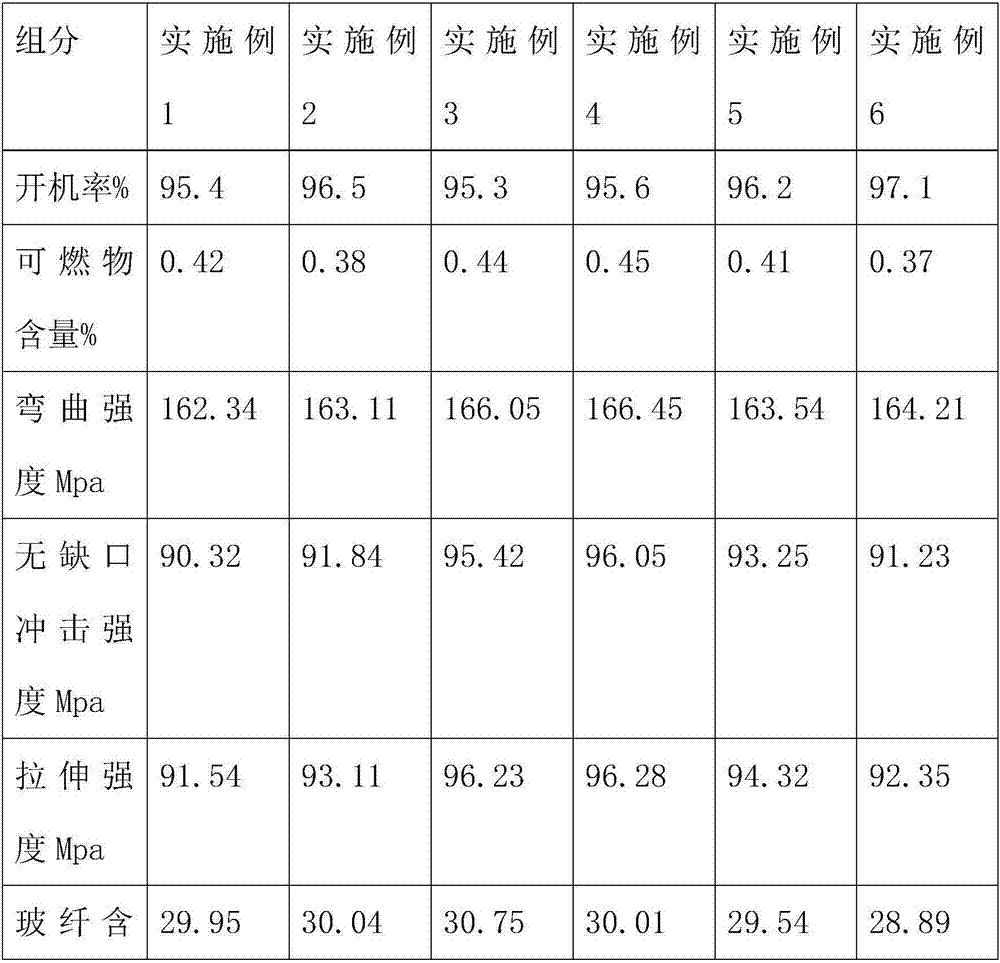

[0021] The silk process is to draw 2000tex raw silk with 5000 holes, bake at 130°C for 14h, and fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com