Inorganic artificial stone containing high-performance ceramsite and superabsorbent resin and preparation method thereof

A high water-absorbent resin and high-performance technology, which is applied in the field of inorganic artificial stone and its preparation, can solve problems affecting product performance and quality, fast hydration time of aluminate cement, cracking of artificial stone, etc., to improve physical and mechanical properties, Avoid shrinkage and reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

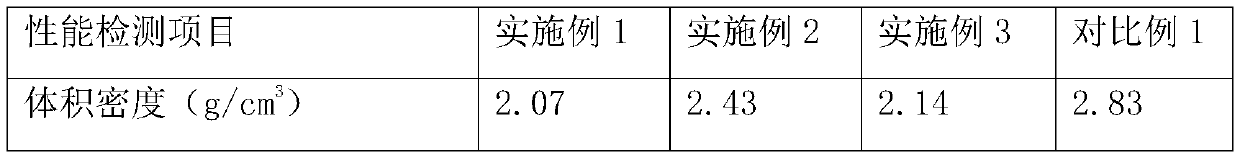

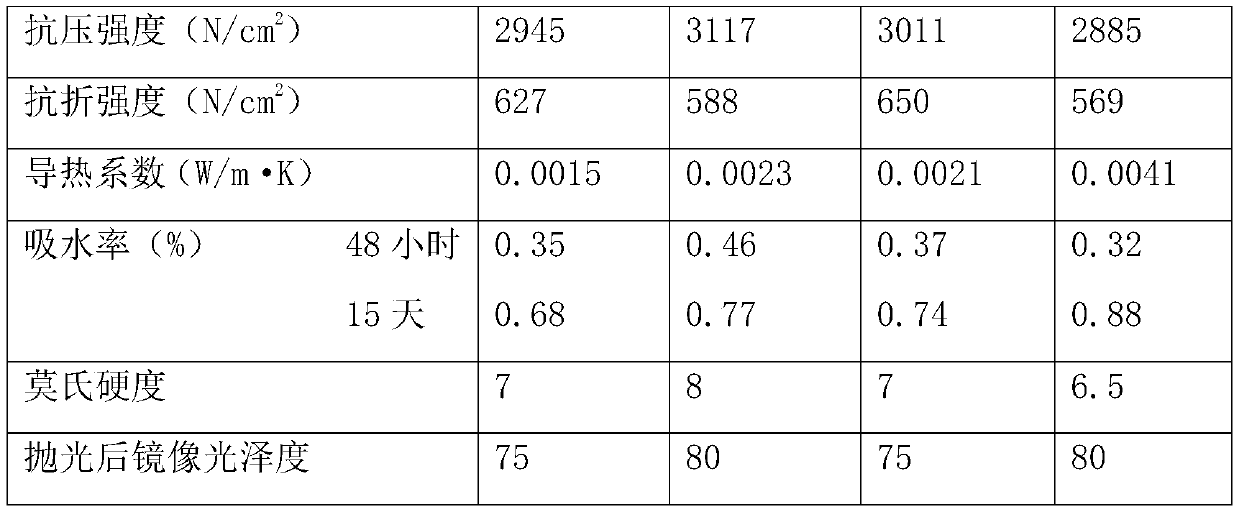

Embodiment 1

[0040] An inorganic artificial stone containing high-performance ceramsite and super absorbent resin, in parts by weight, contains the following components:

[0041] 60 parts of sulphoaluminate cement, 23 parts of fine sand, 15 parts of shale ceramsite, 1 part of polyacrylic resin, 1 part of sodium citrate, 0.5 part of sodium gluconate, 44 parts of water (the amount of water is equivalent to sulphur aluminum The sum of 0.4 times the weight of acid salt cement and 20 times the weight of polyacrylic resin), 0.02-0.05 parts of polyoxypropylene glycerol ether (equivalent to 3-5 drops of polyoxypropylene glycerol ether solution with a concentration of 0.9g / ml ).

[0042] The preparation method of the above-mentioned inorganic artificial stone includes the following steps:

[0043] 1) Put the shale ceramsite and polyacrylic resin in a vacuum mixer and mix for 4 hours;

[0044] 2) The mixture of step 1) is transported to the mixer through a closed and dry conveying device, and the sulphoalu...

Embodiment 2

[0047] An inorganic artificial stone containing high-performance ceramsite and super absorbent resin, in parts by weight, contains the following components:

[0048] 70 parts of sulphoaluminate cement, 10 parts of fine sand, 17 parts of iron tailings ceramsite, 1.5 parts of polyacrylamide resin, 1 part of sodium citrate, 0.5 part of sodium gluconate, 54 parts of water (the amount of water is equivalent to The sum of 0.45 times the weight of sulfoaluminate cement and 15 times the weight of polyacrylamide), 0.02-0.05 parts of polyoxyethylene polypropanolamine ether (equivalent to polyoxyethylene polypropanolamine with a concentration of 0.9g / ml 3-6 drops of ether solution).

[0049] The preparation method of the above-mentioned inorganic artificial stone includes the following steps:

[0050] 1) Put the iron tailings ceramsite and polyacrylamide resin in a vacuum mixer and mix for 4 hours;

[0051] 2) The mixture of step 1) is transported to the mixer through a closed and dry conveying...

Embodiment 3

[0054] An inorganic artificial stone containing high-performance ceramsite and super absorbent resin, in parts by weight, contains the following components:

[0055] Sulphoaluminate cement 65 parts, fine sand 19 parts, shale ceramsite and iron tailing ceramsite mixture 14 parts, polyacrylic resin and polyacrylamide resin mixture 1 part, sodium citrate 0.7 part, sodium gluconate 0.3 part , 44.5 parts of water (the amount of water is the sum of 0.3 times the weight of the sulphoaluminate cement and 25 times the weight of the polyacrylic resin and polyacrylamide resin mixture).

[0056] The preparation method of the above-mentioned inorganic artificial stone includes the following steps:

[0057] 1) Put the mixture of shale ceramsite and iron tailing ceramsite, polyacrylic acid resin and polyacrylamide resin mixture in a vacuum mixer for 4 hours;

[0058] 2) The mixture of step 1) is transported to the mixer through a closed and dry conveying device, and the sulphoaluminate cement, fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com