Formula and making method of plastic tube

A technology of plastic pipes and formulas, which is applied in the field of plastic pipes and pipes, can solve the problems of poor environmental absorption, low strength, and poor toughness, and achieve the effects of less environmental pollution, reasonable formula, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

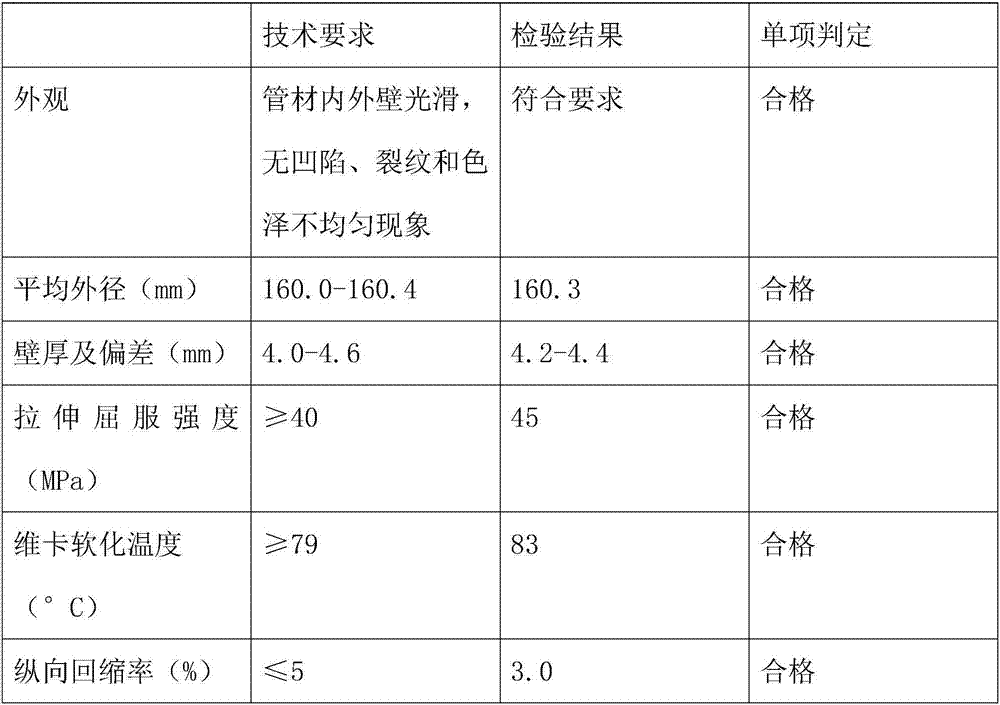

Image

Examples

Embodiment 1

[0026] A plastic pipe, comprising the following components and the proportions of the components are: PVC resin: 100 parts, light calcium carbonate: 8 parts, MBS: 10 parts, liquid calcium-zinc composite stabilizer: 5.5 parts, ACR: 1 part, Paraffin wax: 0.1 part, stearic acid: 0.3 part, light fast red: 0.04 part, permanent orange: 0.04 part.

Embodiment 2

[0028] A plastic pipe, comprising the following components and the proportions of the components are: PVC resin: 110 parts, light calcium carbonate: 9 parts, MBS: 10 parts, liquid calcium-zinc composite stabilizer: 5.5 parts, ACR: 2 parts, Paraffin wax: 0.1 part, stearic acid: 0.4 part, light fast red: 0.04 part, permanent orange: 0.04 part.

Embodiment 3

[0030] A plastic pipe, comprising the following components and the proportions of the components are: PVC resin: 100 parts, light calcium carbonate: 15 parts, MBS: 12 parts, liquid calcium-zinc composite stabilizer: 5.5 parts, ACR: 1 part, Paraffin wax: 0.5 part, stearic acid: 0.3 part, light fast red: 0.04 part, permanent orange: 0.04 part.

[0031] A production process of a plastic pipe, comprising the following steps:

[0032] a) Weigh each raw material according to the weight of the constituent raw materials, add a certain weight of PVC resin into the hot mixing pot, heat for 2 to 3 minutes, and then add a certain weight of toughener, composite stabilizer, lubricant and Colorant, react for 5 to 7 minutes;

[0033] b) In step a), add PVC reclaimed material, reactive polyamide resin, filler and lubricant by weight, react for 10 to 20 minutes, put it in a cold mixing pot, and cool to 32 to 38 ° C;

[0034] c) in step b) the cooling mixture is put into the barrel of the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com