A kind of impregnation resin for reinforcement of aramid honeycomb composite material and its application

A kind of aramid honeycomb, impregnating resin technology, applied in the field of resin, can solve the problem of low bonding strength of aramid honeycomb core, and achieve the effect of improving processability and operability, excellent curing performance and good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

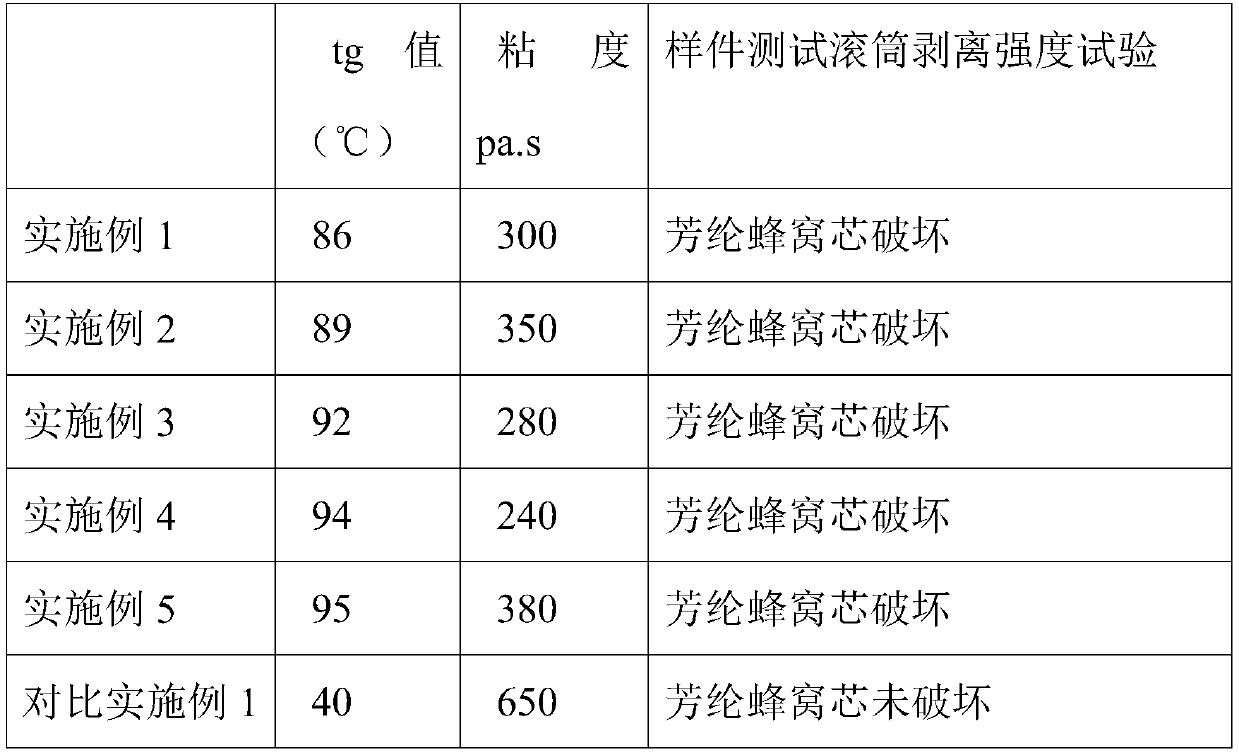

Embodiment 1

[0037] Accurately weigh 100g of bisphenol A epoxy resin E44, 300g of bisphenol A epoxy resin E51, 880g of diglycidyl tetrahydrophthalate, 12.4g of silicone-free foam-breaking polymer solution, The joint agent is 13g, the oily pigment is 2.56g, and the modified alicyclic amine curing agent is 400g. Stir and mix evenly to obtain the impregnating resin for reinforcing the aramid honeycomb composite material with a viscosity of 300mpa.s.

[0038] Take the density as 48kg / m 3 , the aramid honeycomb core material with a cell size of 2.75 is used as a sandwich layer, prepared by this embodiment to obtain impregnated resin coating, and three layers of 0.1mm twill glass cloth are laid on the upper and lower sides, the resin content is 50%-55%, and vacuumized 0.09MPa, the parts are cured at 50°C for 3h.

Embodiment 2

[0040] Accurately weigh 150g of bisphenol A epoxy resin E44, 320g of bisphenol A epoxy resin E54, 1645g of diglycidyl hexahydrophthalate, 5g of silicone-free foam-breaking polymer solution, titanate The coupling agent was 9g, the oily pigment was 0.94g, and the modified alicyclic amine curing agent was 240g. Stir and mix evenly to obtain an impregnating resin for reinforcing aramid honeycomb composite materials with a viscosity of 350mpa.s.

[0041] Take the density as 48kg / m 3 , the aramid honeycomb core material with a cell size of 2.75 is used as a sandwich layer, coated with the impregnated resin prepared in this example, and covered with three layers of 0.1mm twill glass cloth on the upper and lower sides, the resin content is 50%, and the vacuum is 0.09MPa , The parts were cured at 50°C for 3 hours.

Embodiment 3

[0043] Accurately weigh 320g of bisphenol F epoxy resin, 150g of diglycidyl 4,5-epoxycyclohexane-1,2-dicarboxylate, 510g of diglycidyl hexahydrophthalate, without silicone The foam-breaking polymer solution is 19.6g, the silane type coupling agent is 24.5g, the oily pigment is 2g, the modified alicyclic amine curing agent is 980g, stir and mix evenly, and the impregnating resin for aramid honeycomb composite material reinforcement has a viscosity of 280mpa.s.

[0044] Take the density as 48kg / m 3 , the aramid honeycomb core with a cell size of 2.75 is used as a sandwich layer, coated with the impregnated resin prepared in this example, and covered with 3 layers of 0.1mm twill glass cloth on the upper and lower sides, the content of the impregnated resin is about 50%, and the vacuum is 0.09 MPa, the parts are cured at 50°C for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com