Process of preparing high-quality biomass charcoal for carbon-based fertilizer and co-producing wood vinegar

A technology of biomass charcoal and wood vinegar, applied in the direction of biofuel, fertilizer mixture, application, etc., can solve the problems of large pores and low yield of biochar, achieve long-lasting fertilizer effect, avoid pollution, and have good slow-release effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

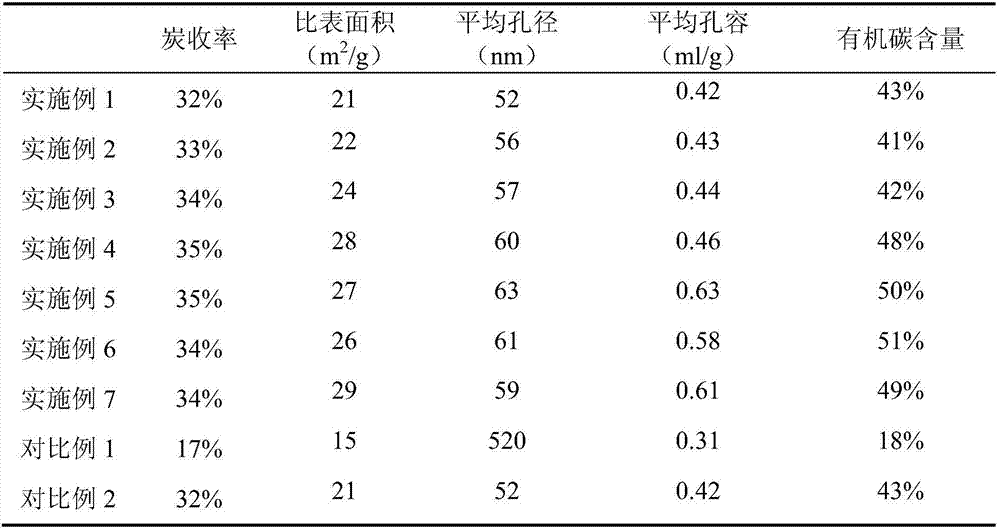

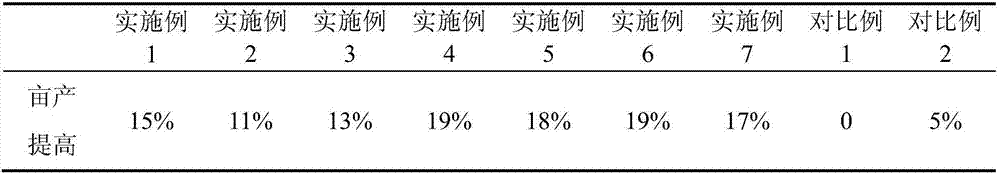

Embodiment 1

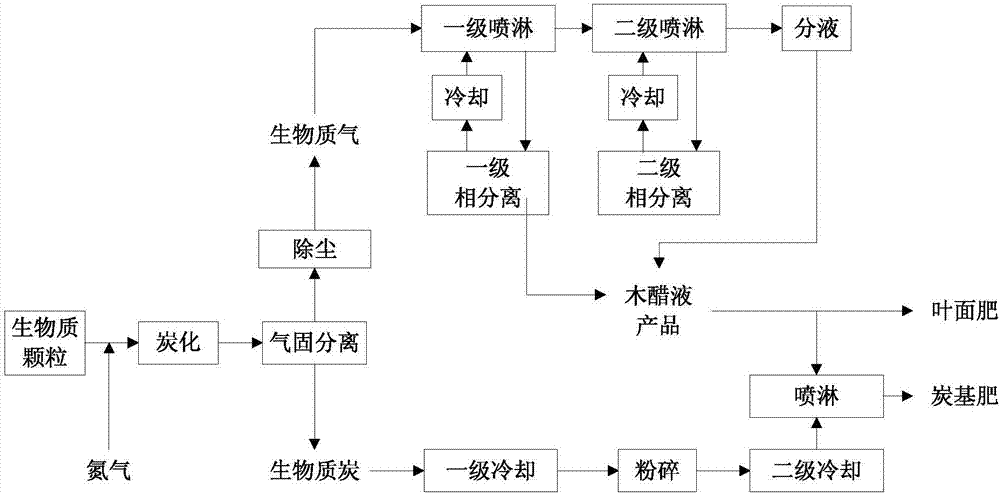

[0034] The technique that utilizes bagasse to prepare high-quality biomass charcoal co-production of wood vinegar for charcoal-based fertilizer provided by the present embodiment comprises the following steps:

[0035] (1) The bagasse was pulverized and carbonized under anaerobic conditions at a carbonization temperature of 450° C. for 88 minutes to obtain a carbonized product.

[0036] (2) The obtained carbonization product is subjected to sedimentation treatment to obtain biochar and biomass gas, and the obtained biochar is subjected to primary cooling, pulverization and secondary cooling in sequence, the cooling method is water cooling, and the biomass gas is cooled by cyclone separation technology. Dedusting is carried out, and the solid particles obtained from dedusting are incorporated into the cooled biochar.

[0037] (3) Collect the biomass gas obtained in step (2), use water as the initial spray agent, and perform primary spray and secondary spray successively to obta...

Embodiment 2

[0046] The technique that utilizes corn cob and bagasse 1:1 mixture to prepare charcoal-based fertilizer that the present embodiment provides high-quality biomass charcoal co-production wood vinegar comprises the following steps:

[0047] (1) After pulverizing the mixed biomass raw material, carbonize it under the condition of anaerobic nitrogen flow, the carbonization temperature is 600° C., and carbonize for 80 minutes to obtain the carbonized product.

[0048] (2) The obtained carbonization product is subjected to sedimentation treatment to obtain biochar and biomass gas, and the obtained biochar is subjected to primary cooling, pulverization and secondary cooling in sequence, the cooling method is water cooling, and the biomass gas is cooled by cyclone separation technology. Dedusting is carried out, and the solid particles obtained from dedusting are incorporated into the cooled biochar.

[0049] (3) Collect the biomass gas obtained in step (2), use water as the initial s...

Embodiment 3

[0058] The technology that the mixture of corncob and bagasse 1:1 provided by the present embodiment is used to prepare high-quality biomass charcoal co-production of wood vinegar for carbon-based fertilizer comprises the following steps:

[0059] (1) The biomass raw material was pulverized, compressed, granulated, and carbonized under the condition of anaerobic nitrogen flow, the carbonization temperature was 480° C., and the carbonization was carried out for 75 minutes to obtain a carbonized product.

[0060] (2) The obtained carbonization product is subjected to sedimentation treatment to obtain biochar and biomass gas, and the obtained biochar is subjected to primary cooling, pulverization and secondary cooling in sequence, the cooling method is water cooling, and the biomass gas is cooled by cyclone separation technology. Dedusting is carried out, and the solid particles obtained from dedusting are incorporated into the cooled biochar.

[0061] (3) Collect the biomass gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com