Moringa oil and preparation method thereof

A technology of moringa oil and moringa seed oil, applied in the directions of fat oil/fat production, fat generation, etc., can solve problems such as restricting the promotion and in-depth development of moringa oil, and achieve improved oxidation stability, long shelf life, and oxidation stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

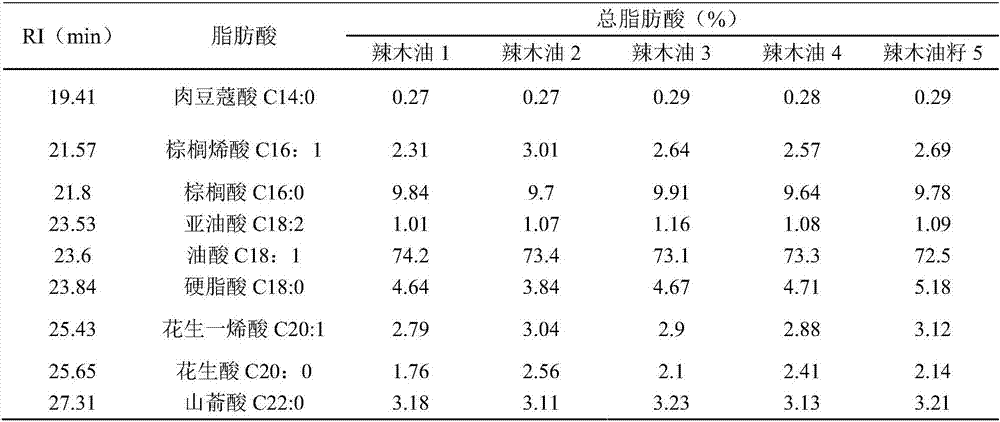

Image

Examples

Embodiment 1

[0080] A kind of preparation of Moringa oil, specifically comprises the steps:

[0081] (1) Microwave treatment: fresh Moringa oleifera seeds are dried and then shelled, heated with a microwave power of 500W for 2 minutes, crushed, passed through a 100-mesh sieve, and crushed in a jet mill for 2 hours to obtain Moringa oleifera seeds with an average particle size of 12 μm pink;

[0082] (2) High-temperature cooking: cooking the obtained Moringa oleifera seed powder for 20 minutes under the steam condition of 100° C.;

[0083] (3) High-pressure homogenization: take the Moringa oleifera seed powder after high-temperature cooking, add deionized water according to the ratio of material to liquid 1:6g / mL, cut at a rate of 8000rpm for 10 minutes, and pass through a colloid mill twice to obtain Moringa oleifera seeds Homogenization solution, 20MPa high pressure homogenization twice;

[0084] (4) Ultrasonic-assisted alkaline extraction: adding sodium hydroxide to the Moringa oleifer...

Embodiment 2

[0090] A kind of preparation of Moringa oil, specifically comprises the steps:

[0091] (1) Microwave treatment: fresh Moringa seeds are dried and then shelled, and after microwave power 600W heat treatment for 3 minutes, crushed, passed through a 100-mesh sieve, and crushed in a jet mill for 2.5 hours to obtain Moringa with an average particle size of 10 μm seed meal;

[0092] (2) High-temperature cooking: the obtained Moringa oleifera seed powder was cooked for 25 minutes under the steam condition of 110° C.;

[0093] (3) High-pressure homogenization: take the Moringa oleifera seed powder after high-temperature cooking, add deionized water according to the ratio of material to liquid 1:7g / mL, cut at a rate of 9000rpm for 15 minutes, and pass through a colloid mill 3 times to obtain Moringa oleifera seeds Homogenization liquid, 30MPa high pressure homogenization 3 times;

[0094] (4) Ultrasonic-assisted alkaline extraction: Add sodium hydroxide to the homogenate of Moringa ...

Embodiment 3

[0100] A kind of preparation of Moringa oil, specifically comprises the steps:

[0101] (1) Microwave treatment: fresh Moringa oleifera seeds are dried and then shelled, heated with a microwave power of 700W for 4 minutes, crushed, passed through a 100-mesh sieve, and crushed in a jet mill for 3 hours to obtain Moringa oleifera seeds with an average particle size of 8 μm pink;

[0102] (2) High-temperature cooking: cooking the obtained Moringa oleifera seed powder for 30 minutes under the steam condition of 120° C.;

[0103] (3) High-pressure homogenization: take the Moringa seed powder after high-temperature cooking, add deionized water according to the ratio of material to liquid 1:8g / mL, cut at a rate of 10000rpm for 20 minutes, and pass through a colloid mill for 3 times to obtain Moringa seeds Homogenization solution, 40MPa high-pressure homogenization twice;

[0104] (4) Ultrasonic-assisted alkaline extraction: add sodium hydroxide to the Moringa oleifera seed powder h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com