Enhanced cathodic arc source for arc plasma deposition

A cathodic arc source and plasma technology, which is applied in the direction of plasma, ion implantation plating, circuits, etc., can solve the problems of low plasma transmission efficiency, reduced carbon film deposition rate, and reduced transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

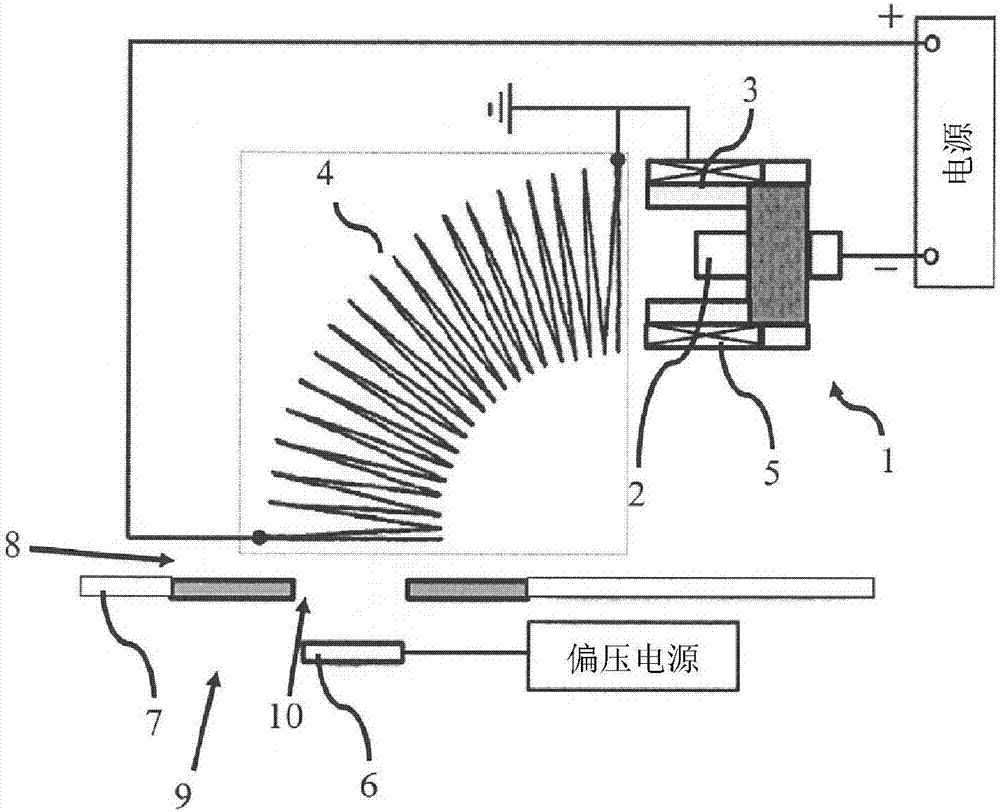

[0026] figure 1 is a schematic diagram illustrating a miniaturized Pulse Filter Cathode Arc (PFCA) source with an open architecture filter. Such as figure 1 As shown in , a miniaturized cathodic arc source 1 has a cathode 2 inside an anode 3 . The cathodic arc source 1 can be located close to the inlet of the filter 4, for example the surface of the cathode 2 is preferably positioned about 0.5 to 2 times the inner diameter of the filter coil relative to the inlet. The cathodic arc source 1 may also include a focusing or injection solenoid 5 to increase the output of plasma from the source to the filter. Filters may be formed from curved solenoidal coils with an open architecture, which typically have at least one of the following features: 1) Additional field injection or focusing coils located at the filter inlet to increase the flow of plasma from the source to the filter. , and 2) coil turns with a flattened cross-section to facilitate reflection of large particles off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com