Stale refuse oxygen-enrichment high-temperature intelligent regulation and control incineration stabilization method

An oxygen-enriched combustion and garbage technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problem of precious landfill area of landfill gas, achieve rapid and thorough repair, solve the problem of large land occupation, and reduce transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with example and accompanying drawing, this method and device are further described

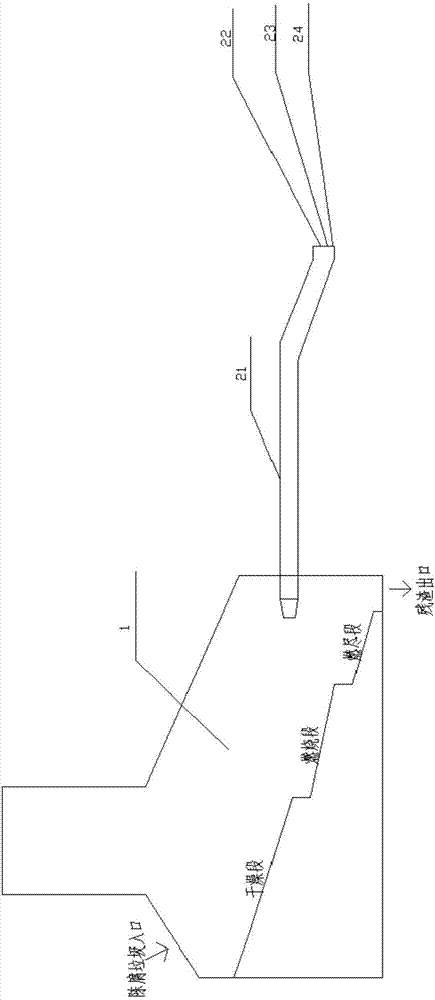

[0029] figure 1 It is a method and device for stable incineration of stale garbage with oxygen-enriched high-temperature intelligent control. The whole system includes a grate incinerator, an oxygen-enriched combustion system and a comprehensive control device for garbage clean combustion. The oxygen-enriched combustion system includes a burner 21, an auxiliary fuel The supply device 22, the oxygen supply device 23, and the ignition fuel supply device 24 are composed of the specific steps and methods:

[0030] 1. Put the stale garbage into the grate incinerator 1, and burn it in the drying section, combustion section and burnout section of the incinerator;

[0031] 2. The gaseous oxygen in the oxygen-enriched combustion system and the ignition fuel (such as fuel oil, gas, etc.) are fully premixed in the burner 21 to form a high-temperature fire core;

[0032] 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com