Preparation method of SiC high-voltage power device junction terminal

A technology of high-voltage power devices and junction terminals, which is applied in the field of preparation of SiC-based high-voltage power device junction terminals, can solve the problems of reducing device reliability and repeatability, increasing device complexity and manufacturing costs, and improving reliability and repeatability. performance, saving device manufacturing cost, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] Using the present invention to prepare SiC high-voltage power devices with 16 steps as an example, a total of 5 etchings, according to Figure 1-Figure 8 The schematic diagram of the preparation of the junction terminal of the SiC high-voltage power device is shown, and the specific preparation steps are as follows:

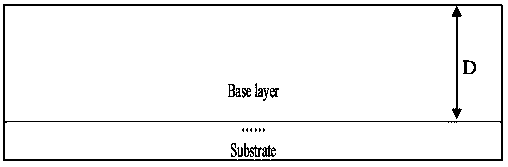

[0020] Step 1: Provide a piece of SiC material structure for preparing a high-voltage power device. Such as figure 1 As shown, the thickness of the SiC layer material layer for preparing the junction terminal in the SiC material layer is D. The semiconductor material may be Si material, SiC material, GaN material, AlN material and the like.

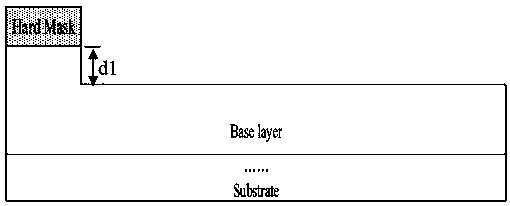

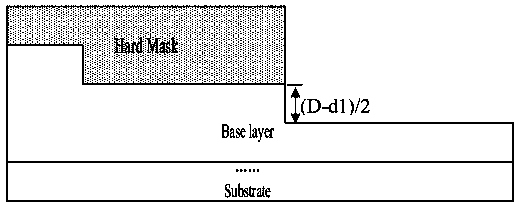

[0021] Step 2: Proceed Level etching makes 1 step. A silicon oxide layer is deposited on the SiC material layer, and the first-level well area is defined by photolithography. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com