Ship desulfurization and denitrification integrated process and ship desulfurization and denitrification integrated device

A desulfurization, denitrification and denitrification technology, applied in the field of ship desulfurization and denitrification integrated process, can solve the problems of complex desulfurization process, economic loss, large floor space, etc., achieve wide application prospects, achieve standard discharge, and small floor space effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

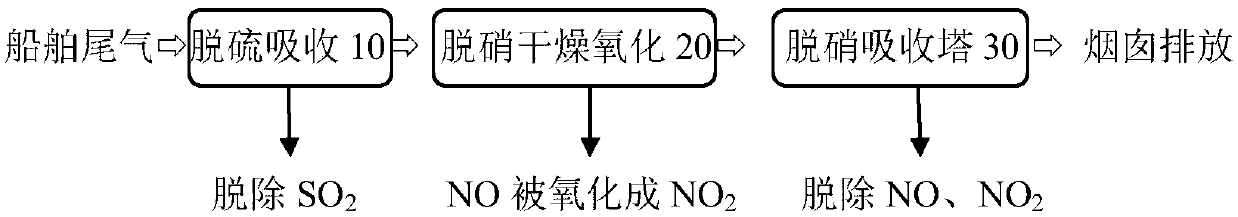

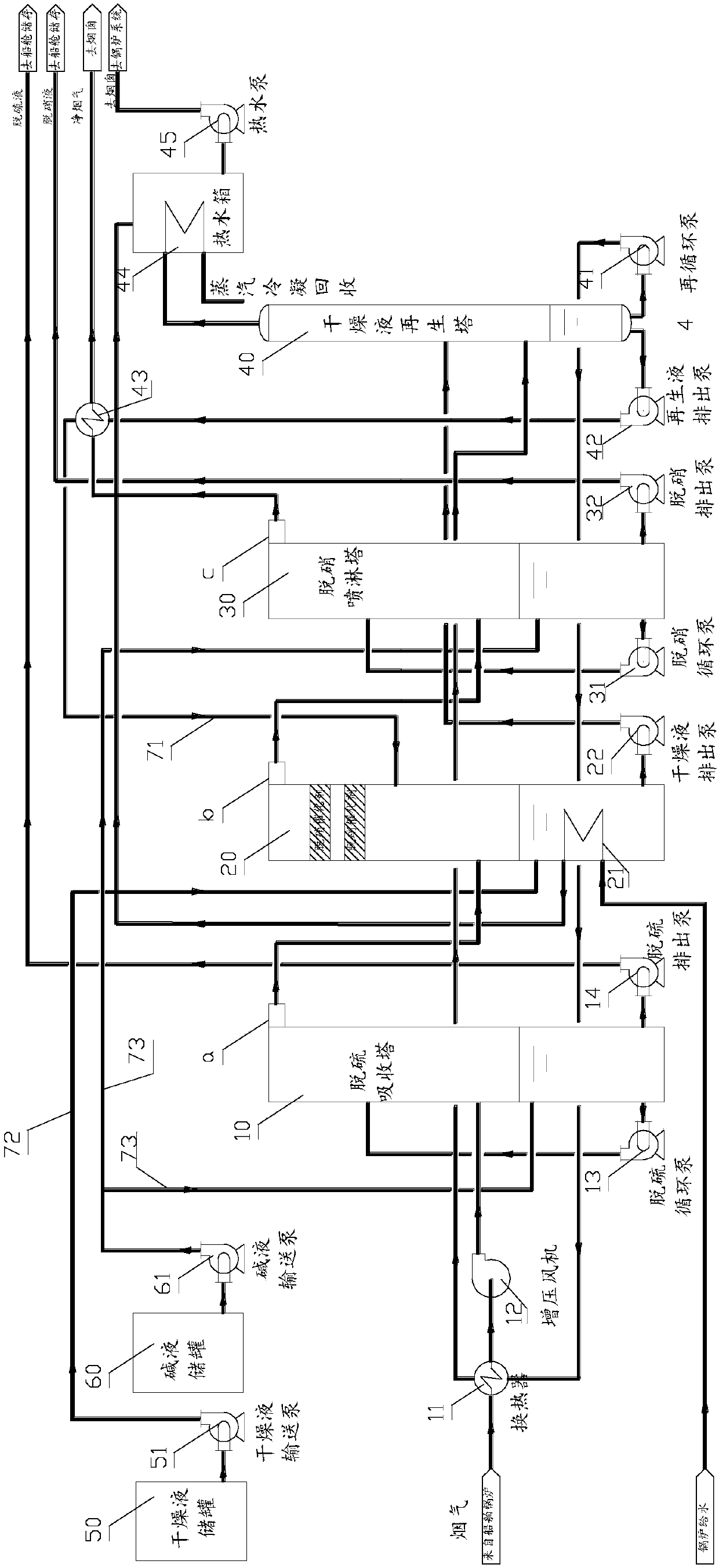

[0070] Such as figure 2 As shown, experiments were performed using the process flow of the present invention.

[0071] according to figure 2 1% NaOH solution is sprayed in the desulfurization spray tower; 60% LiBr solution is sprayed in the denitrification drying oxidation tower, and the upper catalytic zone of the tower is filled with HZSM-5 molecular sieve catalyst, and the mass space velocity is controlled at 0~20,000h -1 , Spray 1% NaOH solution and 0.5% NaSO in the denitration absorption tower 3 The solution absorption liquid, the flue gas enters the integrated desulfurization and denitrification system, and first removes SO in the flue gas through the desulfurization absorption tower 2 , And then enter the denitrification drying oxidation tower to dry, absorb the water vapor in the flue gas, and then use the oxygen in the flue gas to oxidize the NO in the flue gas to NO under the action of the HZSM-5 molecular sieve catalyst 2 , Increase the degree of oxidation, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com