Hydrogenation catalyst filling method

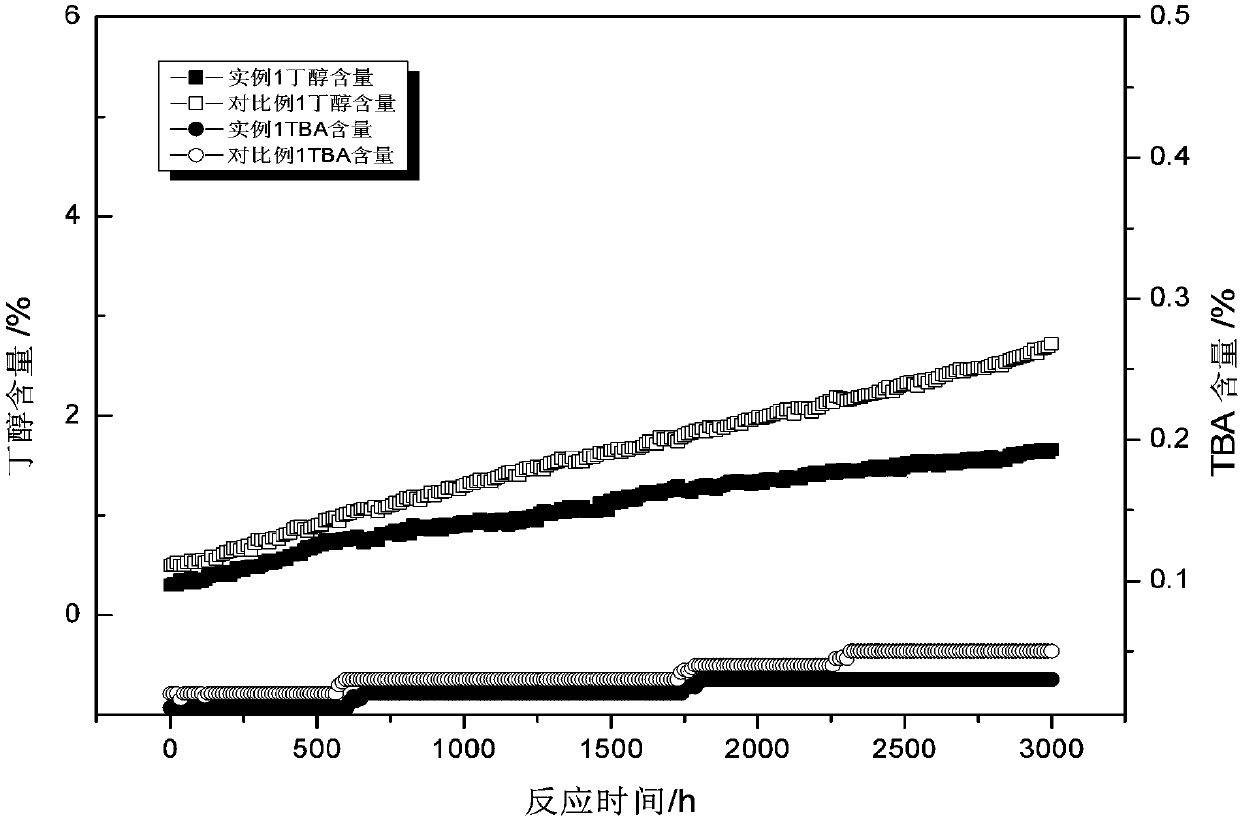

A hydrogenation catalyst and filling technology, which is applied in the field of 1,4-butanediol preparation, can solve the problems that the catalyst occupies a large production time, the catalyst life is shortened, and the product quality is reduced, so as to reduce the content of butanol and impurities TBA content, catalyst life extension, effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

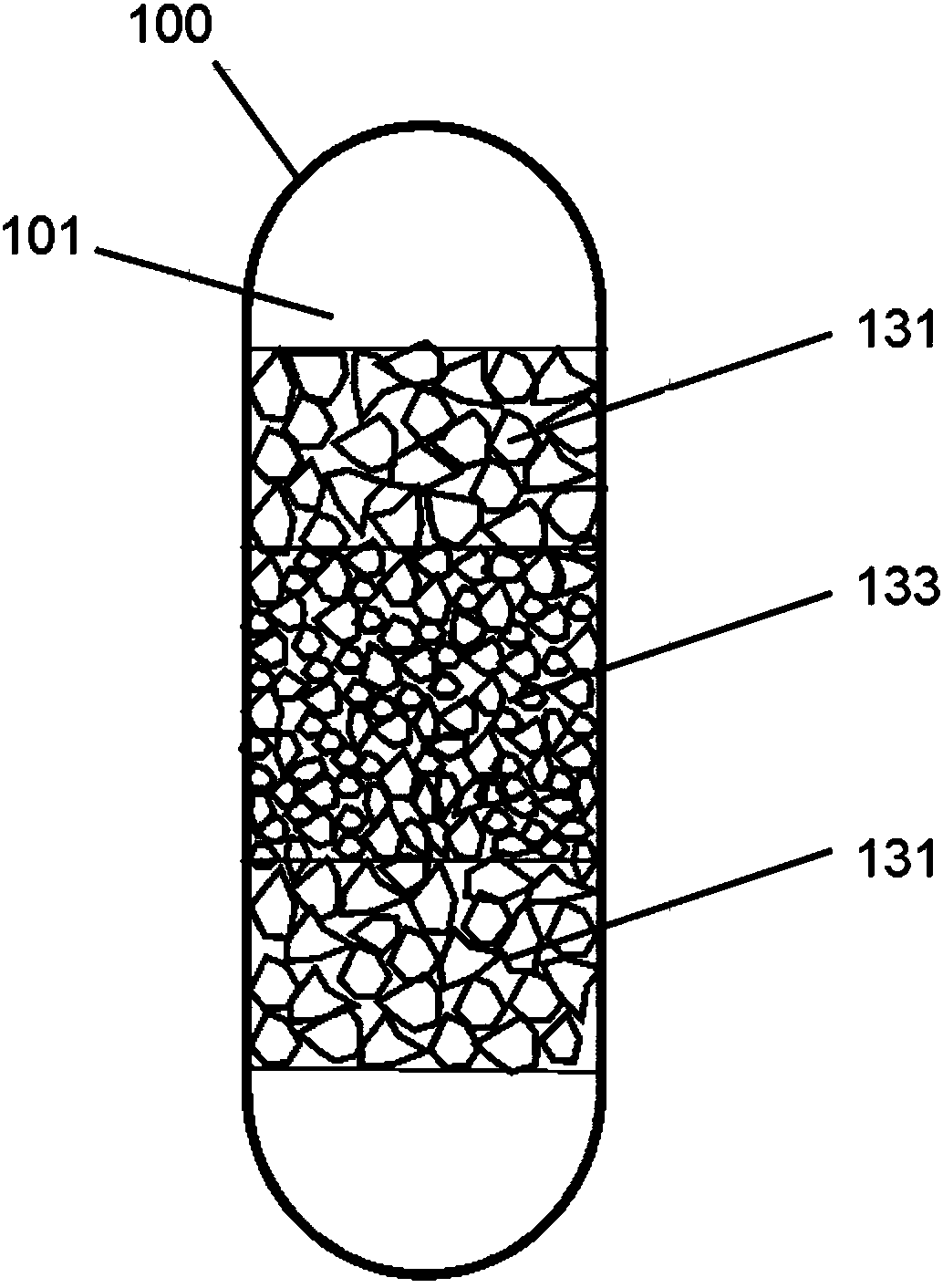

[0023] figure 1 It is a schematic diagram of an embodiment of the hydrogenation catalyst loading method according to the present invention.

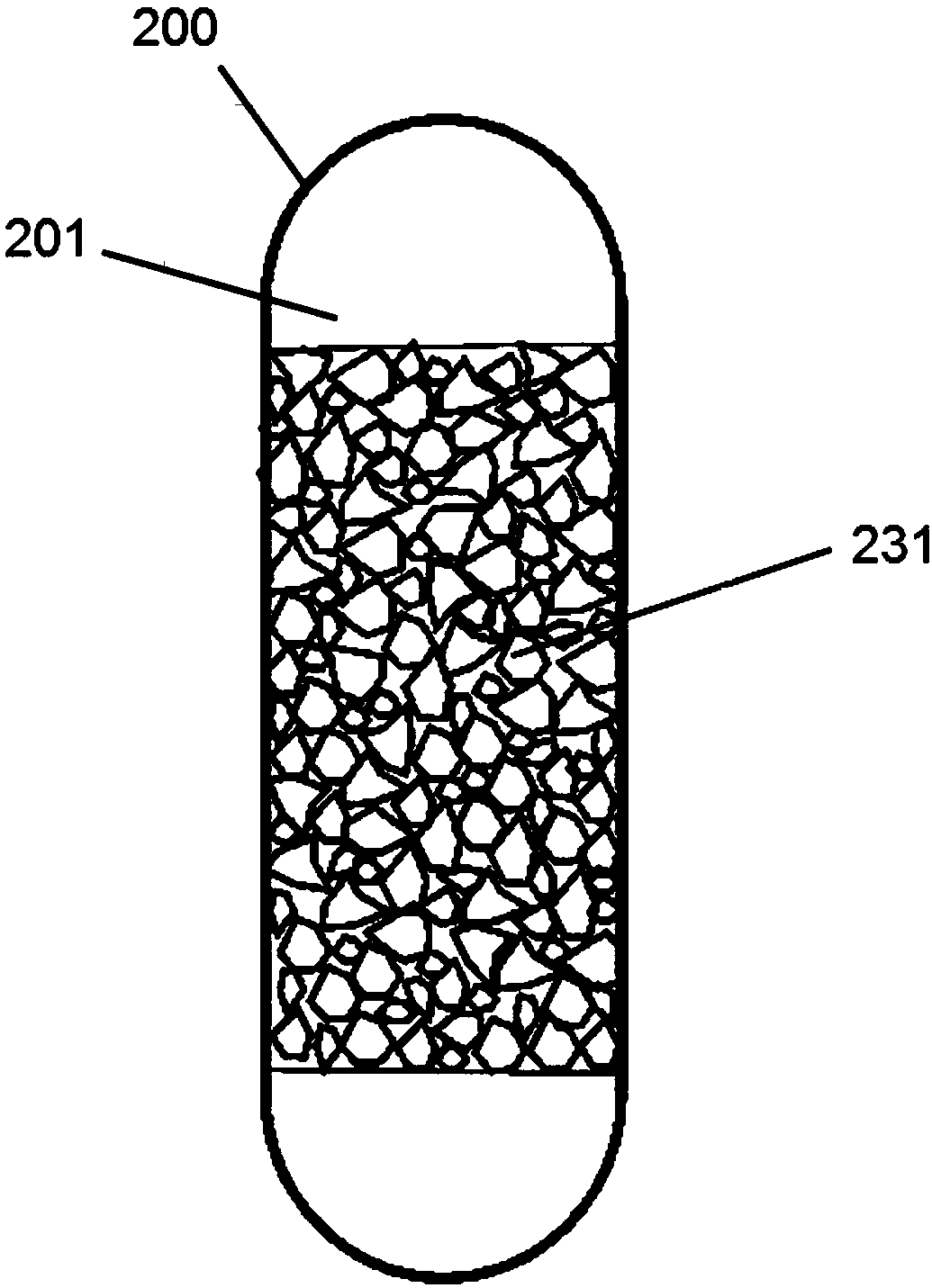

[0024] refer to figure 1 , the present invention provides a hydrogenation catalyst loading method, including providing a fixed bed reactor 100 and hydrogenation catalysts 131 and 133 of two different sizes and specifications, and loading a large-scale hydrogenation catalyst 131 in the fixed bed reactor 100 The upper and lower parts of the chamber 101 are filled with a small-scale hydrogenation catalyst 133 in the middle of the inner chamber 101 of the fixed-be...

Embodiment 1

[0037] Accurately weigh the existing industrial particle size of 3-8 mm, composed of Ni 42 Al 58 5000g of metal alloy particles, obtained by sieving two parts of small-sized metal alloy particles with a particle size of 3-5 mm and large-sized metal alloy particles with a particle size of 5-8 mm, and the large-sized metal alloy particles were divided into two parts, respectively packed In the upper and lower parts of the inner cavity of the fixed-bed reactor, wherein the volume ratio of the upper and lower parts is 1:2, the small-scale metal alloy particles are placed in the middle of the catalyst bed (refer to figure 1 Shown in); Then the lye that starts sodium hydroxide mass concentration to be 0.5%, temperature 20 ℃ flows from the bottom of fixed-bed reactor through particle bed with the speed of 50L / h and then flows out from the top, control reaction solution outlet The temperature is 26-28°C. As the reaction progresses, the concentration of the lye is gradually increased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com