Linear amphiprotic carboxyl-terminated polyether amino silicon oil, cross-linking amphiprotic carboxyl polyether amino silicon emulsion softening agent prepared from same and preparation method of cross-linking amphiprotic carboxyl polyether amino silicon emulsion softening agent

A kind of amino silicone oil, polyether amino technology, applied in textile and paper making, fiber processing and other directions, can solve the problems of demulsification, oil bleaching or delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

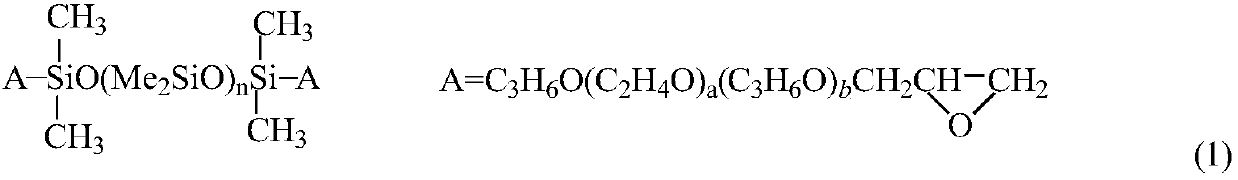

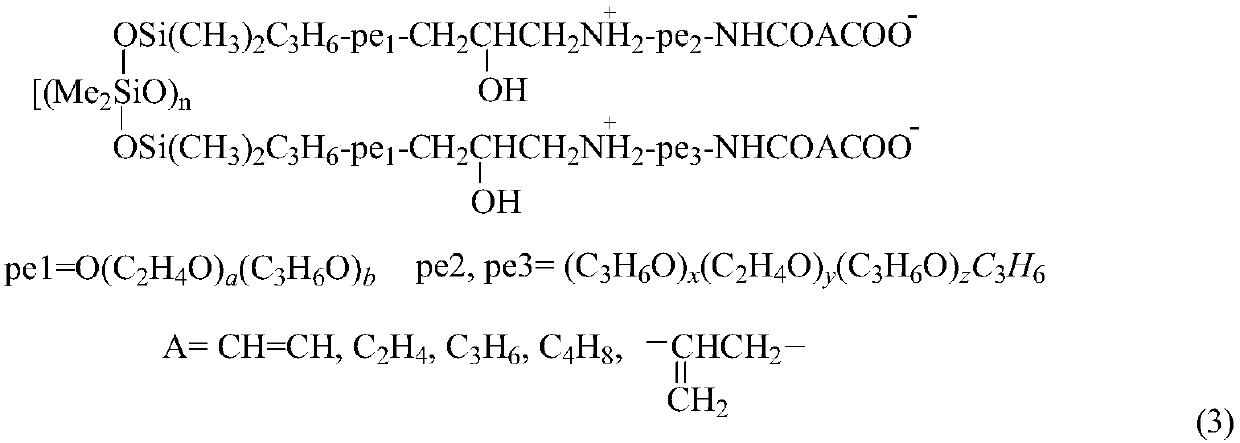

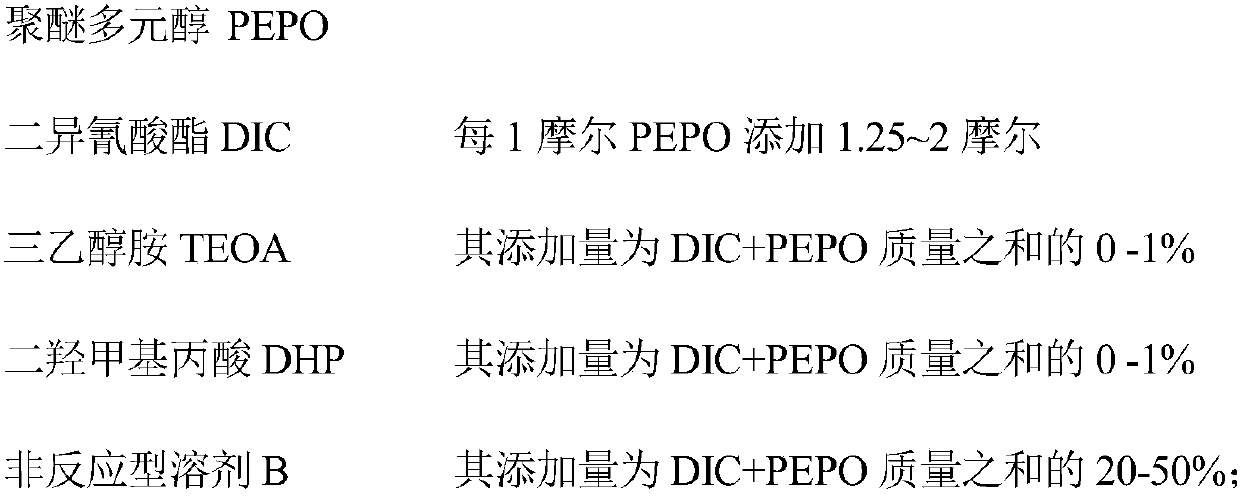

[0035] (1) Preparation of solvent-based linear carboxyl-terminated polyether amino silicone oil: In a three-necked bottle equipped with a thermometer, a reflux condenser and an electric stirrer, the molar ratio of epoxy-terminated polyether silicone oil:polyetheramine is 1:2 Weigh successively 0.01mol (203.58g) of α,ω-EPS-1 and 0.02mol (4.6g) average molecular weight of the structure shown in formula (1), n=270, a=3, b=0, Mn=20358 For 230, x+z=2.5, y=0 structure is H 2 NC 3 h 6 O(C 3 h 6 O) 2.5 C 3 h 6 NH 2 Polyetheramine D230, stirred and mixed, then added 20% by mass of α,ω-EPS-1+D230, about 41.64g of isopropanol solvent, stirred, heated to 80°C for 4h continuous reaction, and then at 80°C , 0.2MPa decompression recovery IPA solvent, get 0.01mol, a total of about 208.18g amino-terminated polyether silicone oil (α, ω-PEAS-1); then, add 20%, about 41.64g ethylene glycol dibutyl ether solvent, adjust the reaction temperature to 70°C, stir, then add 0.02mol, about 1.96g...

Embodiment 2

[0041] (1) Preparation of carboxyl-terminated polyether amino silicone oil: In a three-necked bottle equipped with a thermometer, a reflux condenser and an electric stirrer, weigh the epoxy-terminated polyether-based silicone oil: polyetheramine molar ratio of 1:2 in sequence. Get 0.01mol (48.50g) structure as shown in formula (1), n=25, a=30, b=0, Mn is about the end epoxy polyether silicone oil (α, ω-EPS-2) of 4850 and 0.02 mol (40.00g) average molecular weight is 2000, y=39, x+z=6, structure is H 2 NC 3 h 6 O(C 3 h 6 O) 6 (C 2 h 4 O) 39 C 3 h 6 NH 2 The polyetheramine ED2003, stirred and mixed, then added 200% by mass of α,ω-EPS-2+ED2003, about 177.0g IPA solvent, stirred, heated to 85°C and continued to react for 24h, and then evaporated under reduced pressure to remove IPA Solvent, get 0.01mol, the total amount is about 88.50g amino-terminated polyether silicone oil (α, ω-PEAS-2); then, according to the mass of α, ω-PEAS-2, add 30% diethylene diethylene glycol,...

Embodiment 3

[0047] (1) Preparation of solvent-based carboxyl-terminated polyether amino silicone oil: In a three-necked bottle equipped with a thermometer, a reflux condenser and an electric stirrer, the molar ratio of epoxy-polyether-based silicone oil to polyetheramine is 1:2 Sequentially weigh 0.02mol (211.4g) of epoxy-terminated polyether silicone oil (α,ω-EPS-3) with the structure shown in formula (1), n=133, a=7, b=3, and Mn about 10570 And 0.04mol (24.0g) average molecular weight is 600, y=9, x+z=3.6, structure is H 2 NC 3 h 6 O(C 3 h 6 O) 3.6 (C 2 h 4 O) 9 C 3 h 6 NH 2The polyetheramine ED600, stirred and mixed, then added 60% by mass of α,ω-EPS-3+ED-600, about 141.24g IPA solvent, heated to 80°C for 8 hours, and then recovered the solvent by distillation under reduced pressure IPA, to get 0.02mol, about 235.4g of amino-terminated polyether silicone oil (α,ω-PEAS-3); then, add 25%, about 58.85g of dipropylene glycol dimethyl according to the mass of α,ω-PEAS-3 Ether so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com