Basin resin and preparation method thereof

A technology of resin and basin, applied in the chemical industry, can solve the problems of high cost, waste of resources, poor comprehensive performance of basin, etc., and achieve the effect of improving smoothness, improving dispersion ability and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

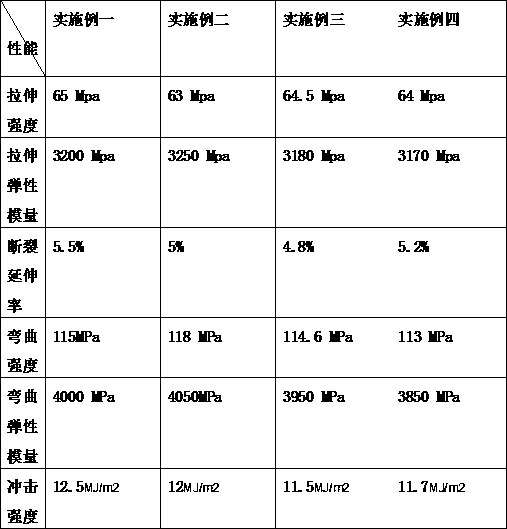

Examples

Embodiment 1

[0023] Embodiment 1, formula: a kind of basin resin, mainly made of the following raw materials: propylene glycol 6, ethylene glycol 7, diethylene glycol 14, phthalic anhydride 26, maleic anhydride 12, organosilicon flame retardant 0.9, paraffin Dispersant 0.8, titanium dioxide 1, styrene 30, wax series release agent 0.5, curing agent 0.5, pearl powder 0.8, defoamer 0.2, self-benzoyl peroxide 0.05.

[0024] The preparation method of basin resin comprises the following steps:

[0025] a) Put propylene glycol, ethylene glycol, diethylene glycol, phthalic anhydride, maleic anhydride, and paraffin-based dispersants into the reaction kettle in turn, start the heating reaction, and start stirring when the temperature of the kettle reaches 120°C;

[0026] b) Under the condition of the nitrogen flow rate of 6m3 / h, the temperature of the distillation head is controlled at 100°C. After holding the heat for 1 hour, the reaction will exotherm to 140°C by itself. The temperature is raised...

Embodiment 2

[0031] Embodiment 2, formula: a kind of basin resin, mainly made of the following raw materials: propylene glycol 7, ethylene glycol 8, diethylene glycol 16, phthalic anhydride 28, maleic anhydride 14, organosilicon flame retardant 1.5, paraffins Dispersant 1, titanium dioxide 1.5, styrene 32, wax series release agent 1, curing agent 0.8, pearl powder 1.2, defoamer 0.5, self-benzoyl peroxide 0.1.

[0032] The preparation method of basin resin comprises the following steps:

[0033] a) Put propylene glycol, ethylene glycol, diethylene glycol, phthalic anhydride, maleic anhydride, and paraffin-based dispersants into the reaction kettle in turn, start the heating reaction, and start stirring when the temperature of the kettle reaches 120°C;

[0034] b) Under the condition of a nitrogen flow rate of 10m3 / h, the temperature of the distillation head is controlled at 105°C. After 1.5 hours of heat preservation reaction, the reaction automatically exotherms to 140°C, and the temperatu...

Embodiment 3

[0039] Embodiment 3, formula: a kind of basin resin, mainly made of the following raw materials: propylene glycol 6.5, ethylene glycol 7.5, diethylene glycol 15, phthalic anhydride 27, maleic anhydride 13, organosilicon flame retardant 1, paraffin Dispersant 0.9, titanium dioxide 1.2, styrene 31, wax series release agent 0.8, curing agent 0.7, pearl powder 1, defoamer 0.3, self-benzoyl peroxide 0.07.

[0040] The preparation method of basin resin comprises the following steps:

[0041] a) Put propylene glycol, ethylene glycol, diethylene glycol, phthalic anhydride, maleic anhydride, and paraffin-based dispersants into the reaction kettle in sequence, start the heating reaction, and start stirring when the temperature of the kettle reaches 130°C;

[0042] b) Under the condition of a nitrogen flow rate of 7m3 / h, the temperature of the distillation head is controlled at 103°C. After 1.2 hours of heat preservation reaction, the reaction automatically exotherms to 140°C, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com