A kind of thermal insulation nanocomposite coating and preparation method thereof

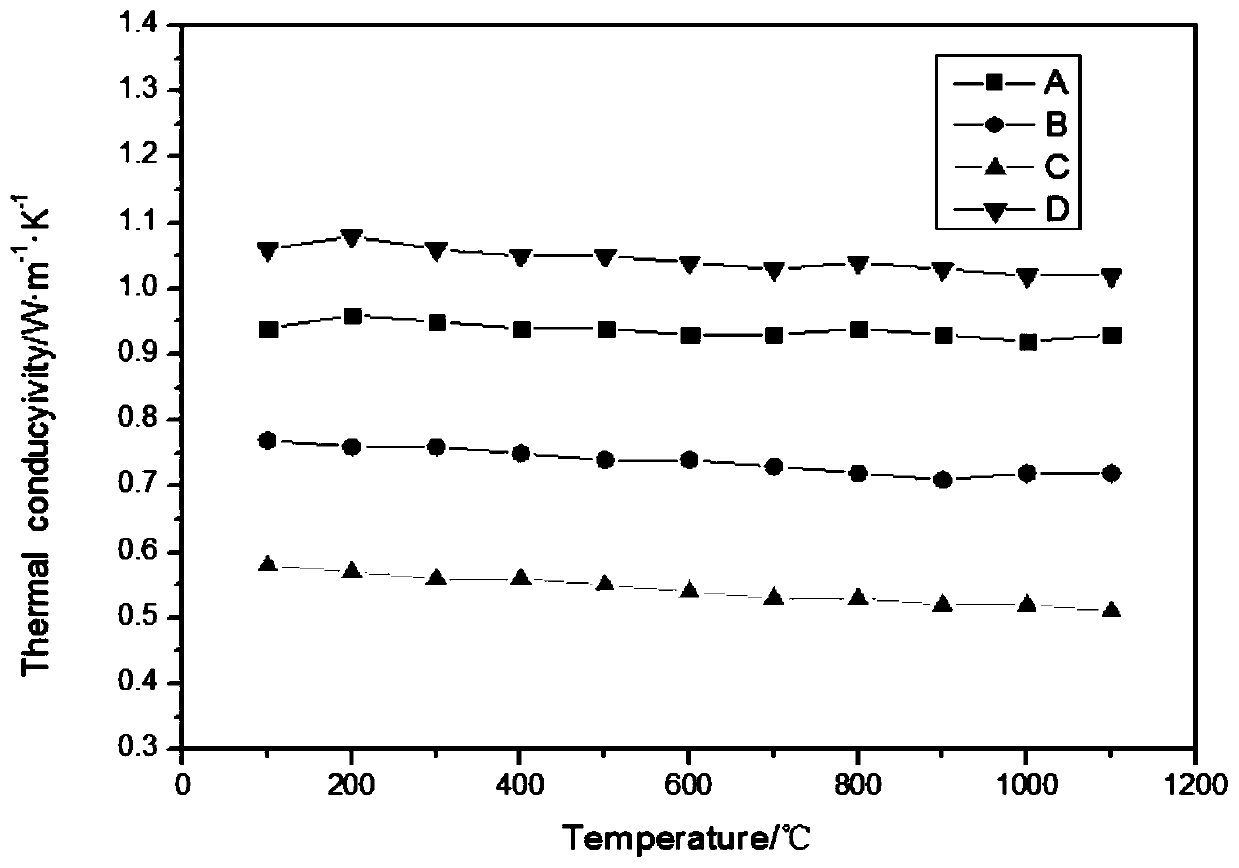

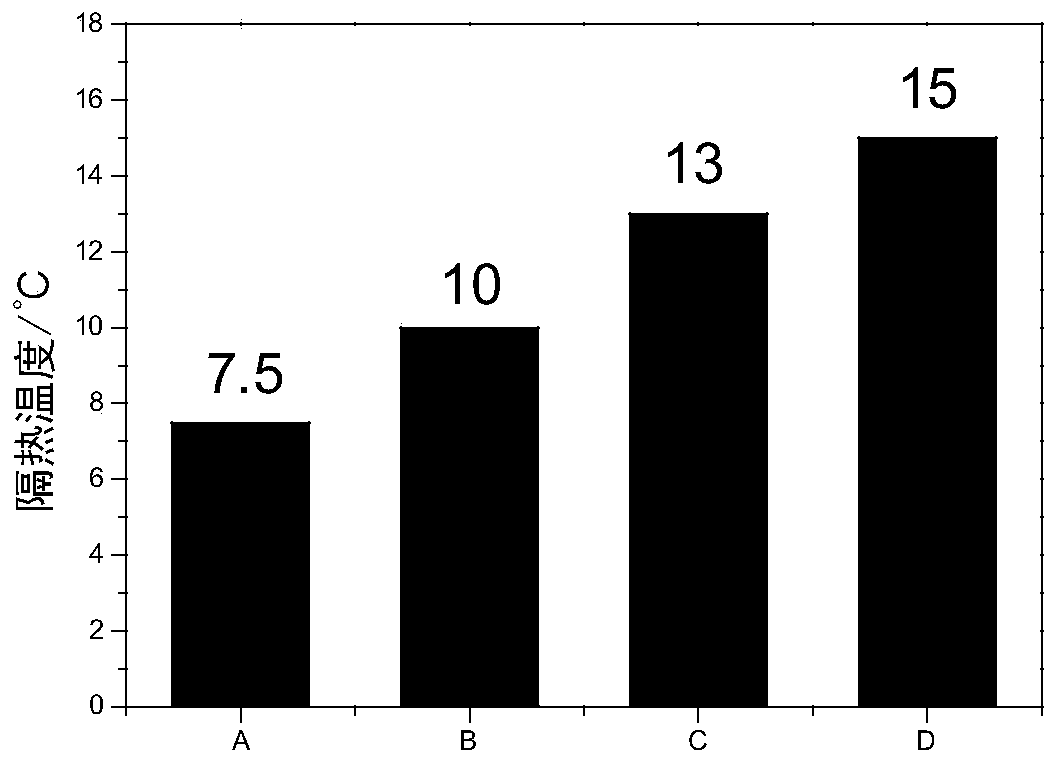

A nanocomposite and composite coating technology, applied in the field of coatings, can solve the problems of reinforcement, poor machine properties, coating coverage, etc., and achieve the effects of improving mechanical properties, increasing coating coverage, and excellent heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

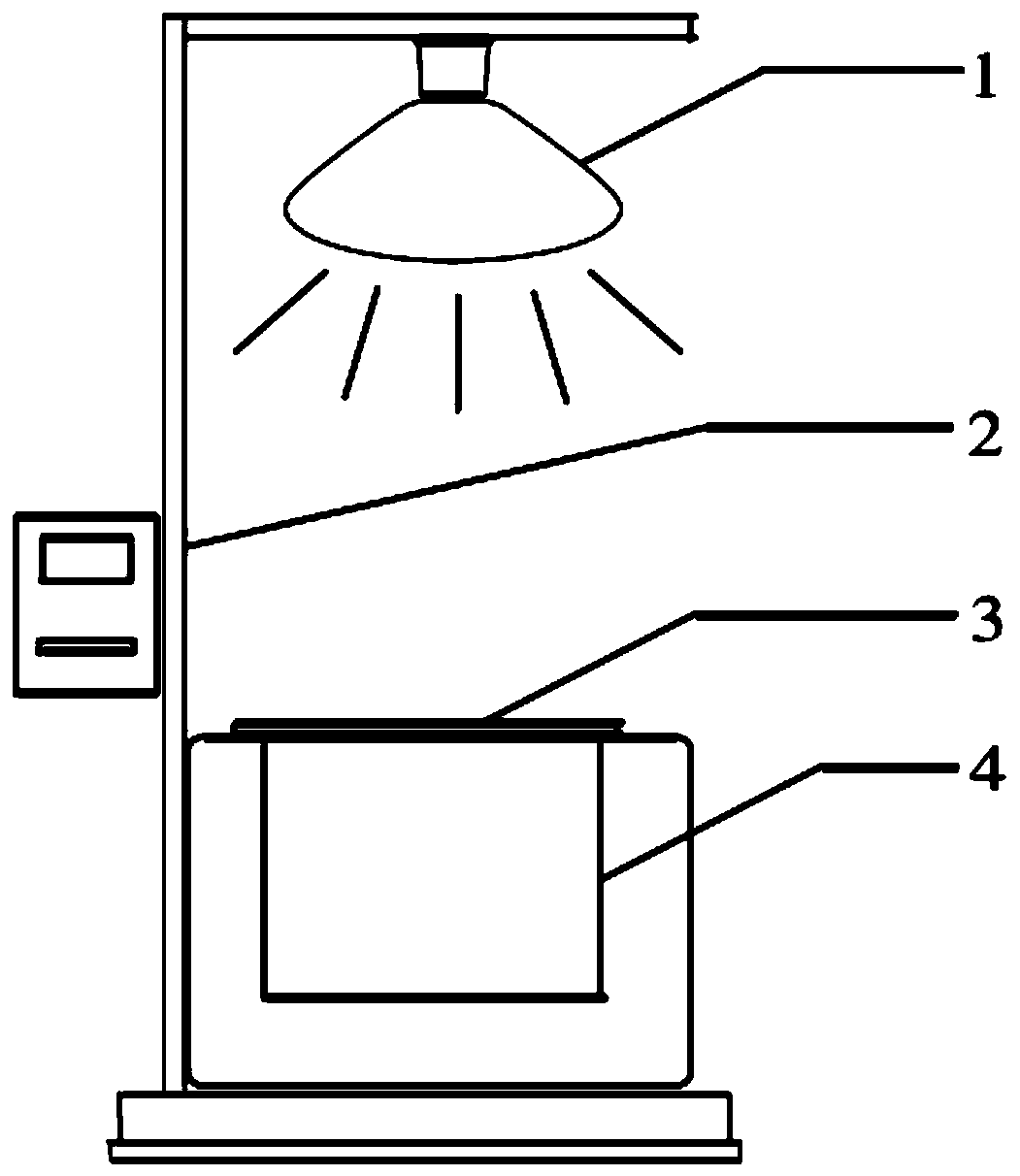

Image

Examples

Embodiment 1

[0021] Example 1: Waterborne epoxy coating without any filler added.

[0022] Preparation of paint: 1) Take 100 parts of water-based epoxy resin and 100 parts of water,

[0023] 2) Disperse in a ball mill for 4 hours.

[0024] 3) Take 50 parts of water-based curing agent and 100 parts of water to mix evenly; mix the mother liquor of water-based epoxy coating with diluted water-based curing agent in a ratio of 4:1 and apply it on the treated metal substrate to control the thickness 50-200um, cure at room temperature.

Embodiment 2

[0025] Example 2: Waterborne epoxy coating with only cellulose aerogel added.

[0026] (1) Preparation of cellulose aerogel: In a beaker containing 10g of 1.4% cellulose microfiber suspension, adjust the pH to 4 with hydrochloric acid, stir for 2h at a speed of 500rpm and a temperature of 25℃, and freeze-dry the sample , Prepare a cellulose aerogel.

[0027] (2) Preparation of cellulose aerogel coating: take 100 parts of water-based epoxy resin and 100 parts of water, take 30 parts of cellulose aerogel filler, add to the above resin system, and disperse in a ball mill for 4 hours. Take 50 parts of water-based curing agent and 100 parts of water and mix uniformly; mix the mother liquor of the water-based epoxy composite thermal insulation coating with the diluted water-based curing agent in a ratio of 4:1 and apply it on the processed metal substrate, control The thickness is 50-200um, and it can be cured at room temperature.

Embodiment 3

[0028] Example 3: Waterborne epoxy coating with only gadolinium zirconate nanomaterials added.

[0029] (1) Preparation of nanometer gadolinium zirconate coating by co-precipitation method: take 6 parts of gadolinium oxide (Gd 2 0 3 ), 10 parts of zirconium oxychloride (ZrOCl 2 ·8H 2 O), others are analytical grade. ZrOCl 2 .8H 2 0 is dissolved in 25 parts of ammonia water, fully reacted to obtain a white flocculent precipitate, washed 6 times with absolute ethanol and deionized water, and then fully dissolved in 25 parts of HN0 3 , Get ZrO(N0 3 ) 2 Solution. Gd 2 0 3 Dissolve in 5 parts of nitric acid to make Gd(N0 3 ) 3 Solution. The two solutions were mixed to prepare a mother salt solution with a cation concentration of 0.05 mol / L, which was dropped into concentrated ammonia water to obtain a precipitate. After aging for 24 hours, it was filtered, dried in an oven at 60°C, and ground and sieved. Calcined in a muffle furnace at 800℃ for 4-6h to obtain Gd 2 Zr 2 O 7 Nano powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com