Adhesive glue for optical fiber ring and preparation method thereof

An optical fiber ring and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, non-polymer adhesive additives, etc., can solve the problems of small creep, reduction, and inability to meet performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

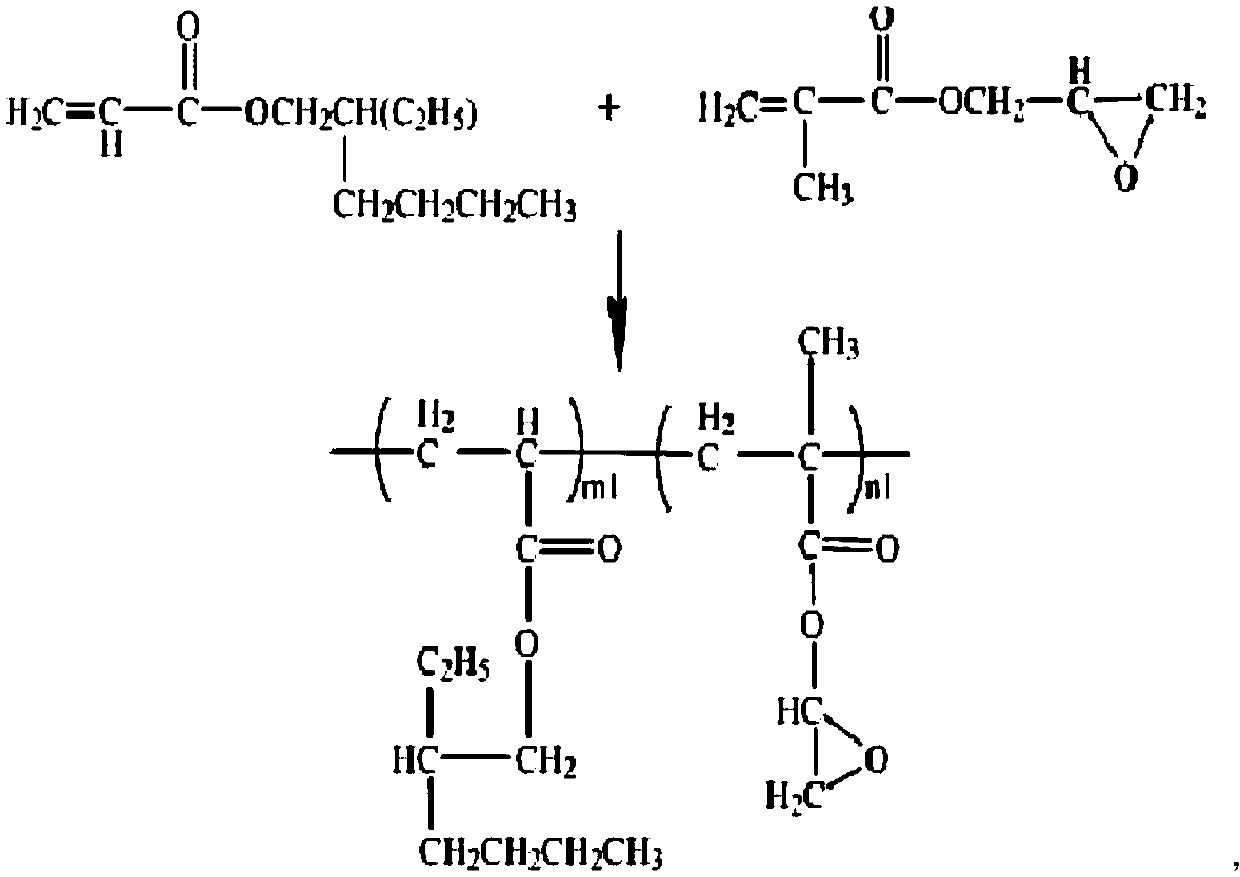

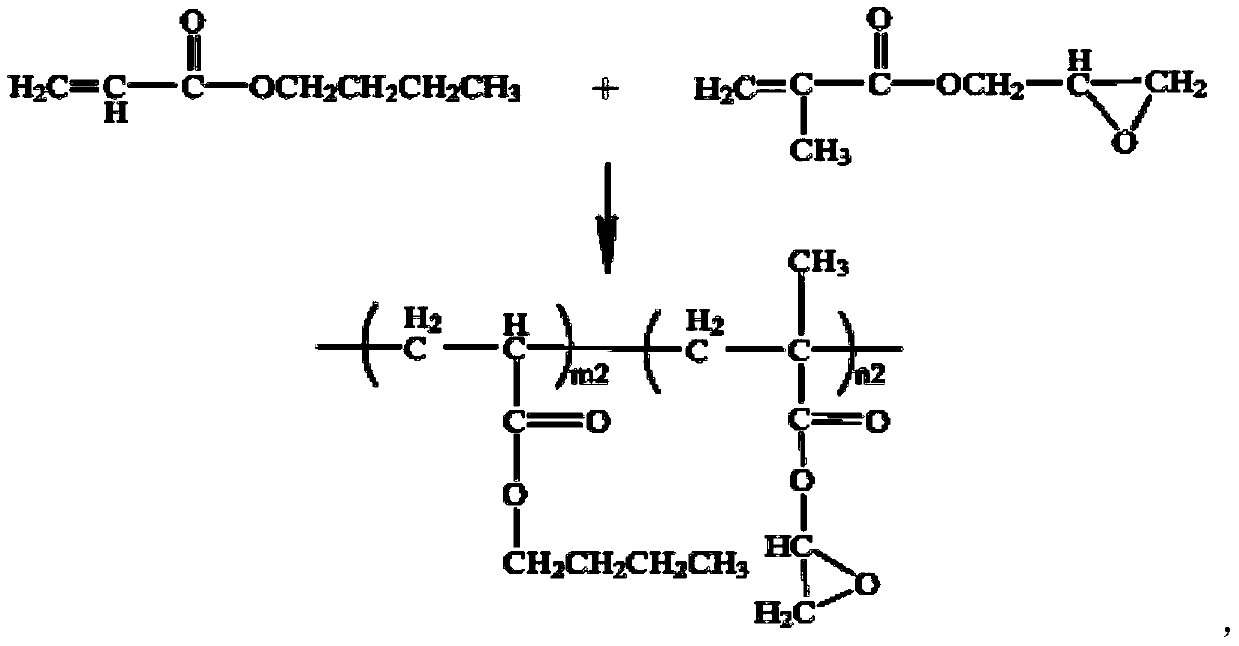

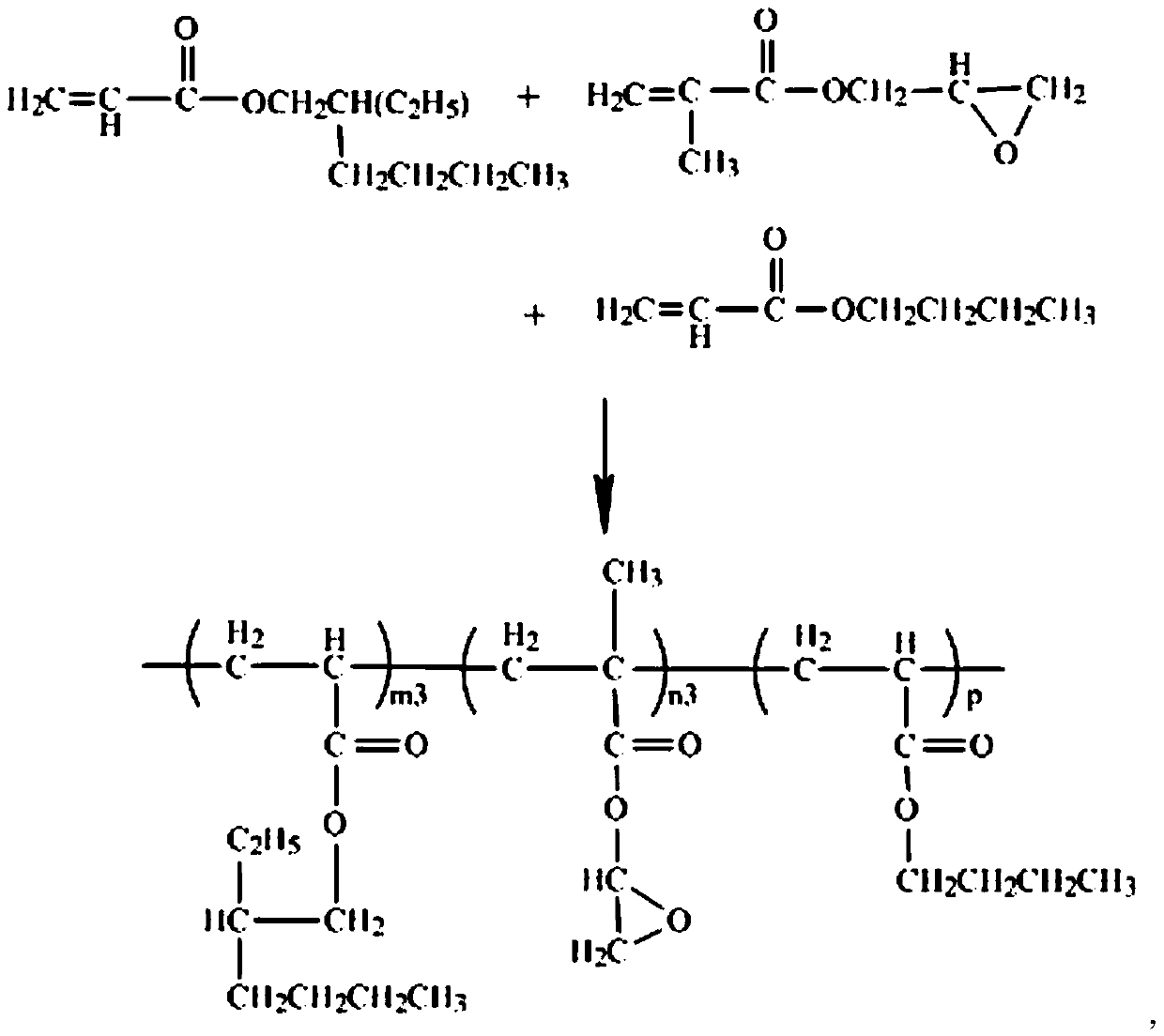

Method used

Image

Examples

Embodiment 1-1

[0053] Dissolve the di-secondary amine compound and tetrahydrofuran in a molar ratio of 1:3, dissolve N,N'-dimethylethylenediamine in tetrahydrofuran in reactor A, under nitrogen protection, and then add trimethylolpropane Triacrylate (TMPTA) and tetrahydrofuran are mixed evenly according to the molar ratio of 1:1, then quickly added to reactor A, and mixed evenly, trimethylolpropane triacrylate and N,N'-dimethylethane in reactor A The molar ratio of diamine is 1:2, react for 24 hours at 30℃~40℃ under the protection of nitrogen, remove tetrahydrofuran by evaporation, wash with ether several times, and dry in an oven at 50℃~60℃ with a vacuum of 0.08~0.09MPa for 3h , to obtain flexible amino resin A1.

Embodiment 1-2

[0055] The di-secondary amine compound and tetrahydrofuran are taken according to the molar ratio of 1:4, and N,N'-dimethylpropylenediamine is dissolved in tetrahydrofuran in reactor A. Under the protection of nitrogen, trimethylolpropane Triacrylate (TMPTA) and tetrahydrofuran are mixed evenly according to the molar ratio of 1:3, then quickly added to reactor A, and mixed evenly, trimethylolpropane triacrylate and N,N'-dimethylpropane in reactor A The molar ratio of diamine is 1:3, react at 30℃~40℃ under the protection of nitrogen for 24h, remove tetrahydrofuran by evaporation, wash with diethyl ether several times, and dry in an oven at 50℃~60℃ with a vacuum of 0.08~0.09MPa for 3h , to obtain flexible amino resin A2.

Embodiment 1-3

[0057] The di-secondary amine compound and tetrahydrofuran are taken according to the molar ratio of 1:5, piperazine is dissolved in tetrahydrofuran in reactor A, and under nitrogen protection, trimethylolpropane triacrylate (TMPTA) and tetrahydrofuran are then The molar ratio of 1:6 is mixed evenly, then quickly added to the reactor A, mixed evenly, the molar ratio of trimethylolpropane triacrylate to piperazine in the reactor A is 3:5, under the protection of nitrogen at 30 ° C ~ 40 ° C React at low temperature for 24 hours, remove tetrahydrofuran by evaporation, wash with ether several times, and dry in an oven at 50°C to 60°C for 3 hours under a vacuum of 0.08 to 0.09MPa to obtain flexible amino resin A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com