Method and system for hydroconversion of coal tar raw material

A hydrogenation conversion and coal tar technology, applied in the field of coal tar raw material hydrogenation conversion, coal tar raw material hydrogenation conversion system field, can solve the problems of long-term stable operation, coke blockage of reactor internal components, etc., to solve the problem of fixed The effect of short operation period, improved utilization rate and utilization value, and high liquid yield of bed coal tar hydrogenation unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

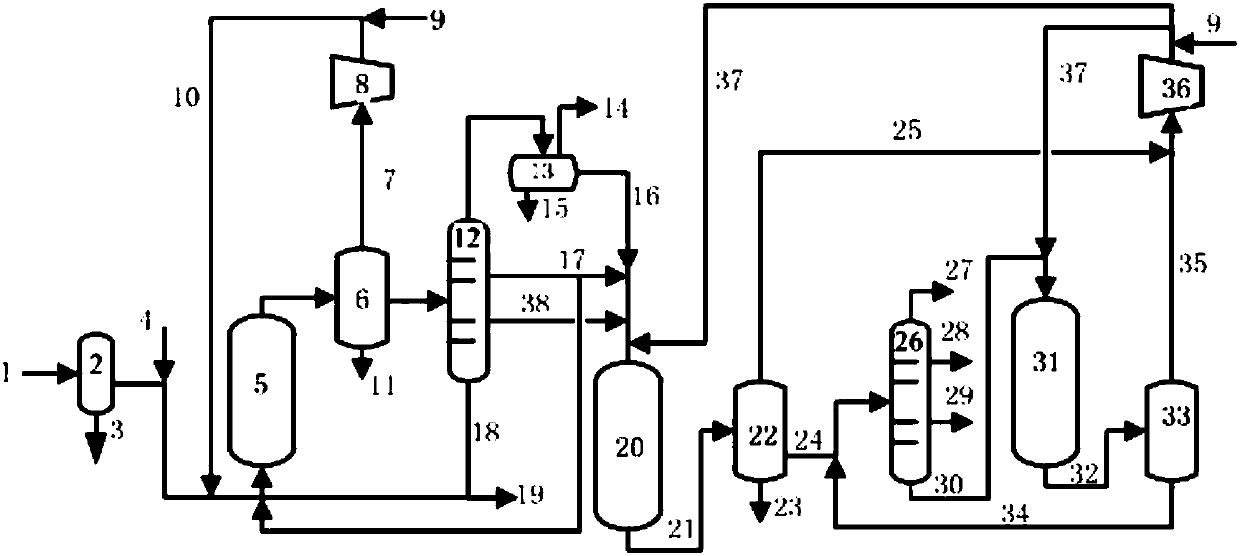

Method used

Image

Examples

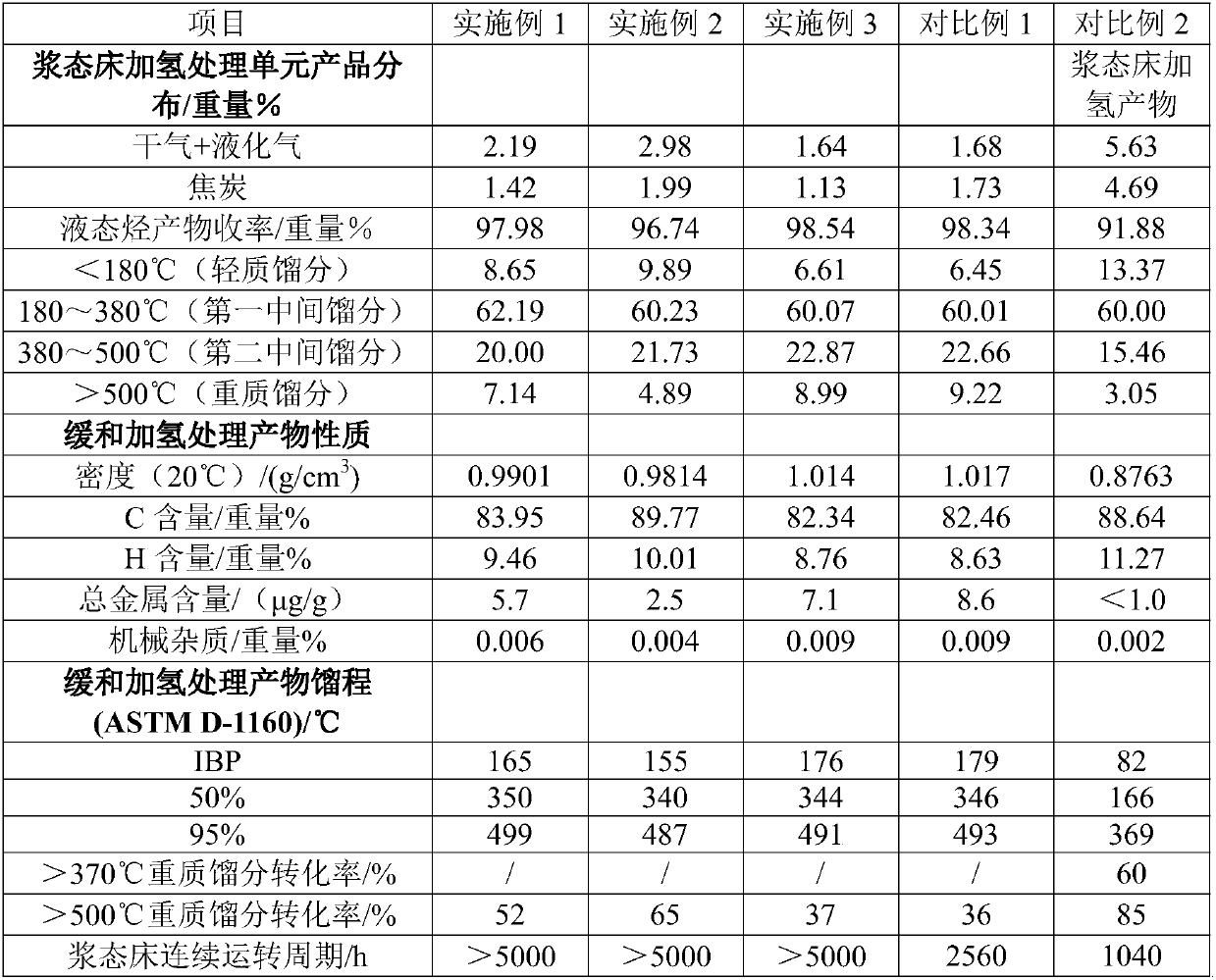

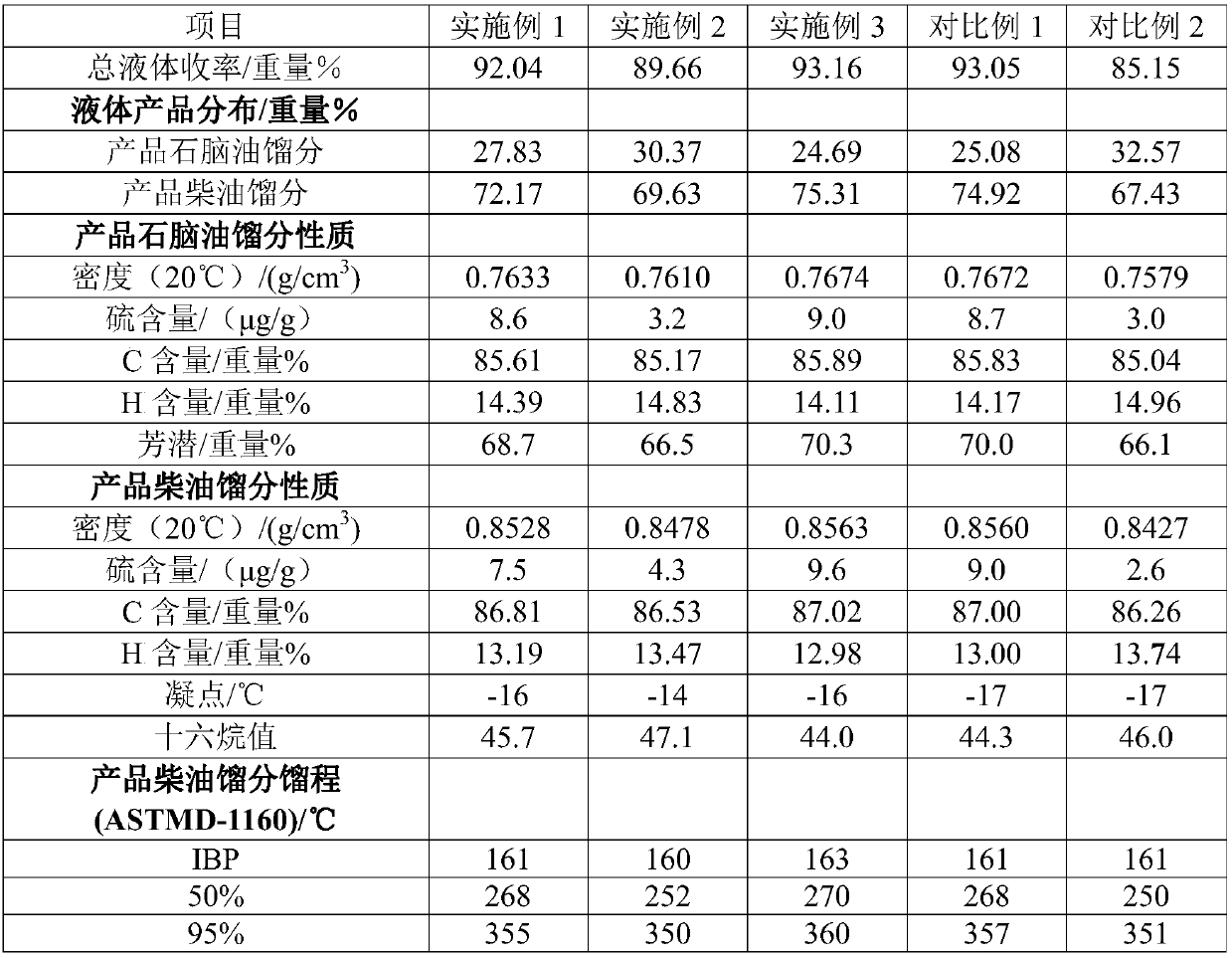

Embodiment 1

[0120] Based on the total weight of the coal tar raw material, the dosage of the slurry bed catalyst is 1.5% by weight based on the active metal elements contained therein. After mixing the coal tar raw material in Table 1 with the aforementioned highly dispersed heterogeneous slurry bed catalyst, they enter the slurry bed hydrogenation reactor together with hydrogen for gentle hydrogenation treatment, and the outflow of the slurry bed hydrogenation reactor The product enters the first separation unit for gas-liquid separation, and separates water, and the separated liquid hydrocarbon product enters the first fractionation tower, and is distilled and cut into light distillate, first middle distillate, second middle distillate and heavy distillate. Taking the corresponding heavy fraction in the coal tar raw material entering the slurry bed hydrogenation reactor as a benchmark, the conversion rate of the heavy fraction in the raw material is controlled to be 52%. Wherein the fir...

Embodiment 2

[0129] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0130] Based on the total weight of the coal tar raw material, the dosage of the slurry bed catalyst is 2.0% by weight based on the active metal elements contained therein. The coal tar raw material is uniformly mixed with the aforementioned high-dispersion heterogeneous slurry-bed catalyst, and then enters the slurry-bed hydrogenation reactor together with hydrogen for mild hydrogenation treatment.

[0131] Taking the corresponding heavy fraction in the coal tar raw material entering the slurry bed hydrogenation reactor as a benchmark, the conversion rate of the heavy fraction in the slurry bed hydrogenation reactor is controlled to 65%. 60% by weight of the heavy fraction cut out by the first fractionation tower is thrown out of the device, and the rest of the heavy fraction is recycled back to the slurry bed hydrogenation reactor for further conversion.

[0132] 25% by we...

Embodiment 3

[0140] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0141] Based on the total weight of the coal tar raw material, the amount of the slurry bed catalyst is 0.3% by weight based on the active metal elements contained therein. The coal tar raw material is uniformly mixed with the aforementioned high-dispersion heterogeneous slurry-bed catalyst, and then enters the slurry-bed hydrogenation reactor together with hydrogen for mild hydrogenation treatment.

[0142] Taking the corresponding heavy fraction in the coal tar raw material entering the slurry bed hydrogenation reactor as a benchmark, the conversion rate of the heavy fraction in the slurry bed hydrogenation reactor is controlled to be 37%. Wherein the heavy fraction of 40% by weight cut out by the first fractionation tower is thrown out of the device, and the rest of the heavy fraction is recycled back to the slurry bed hydrogenation reactor for further conversion.

[0143...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com