Flake ice potential tower turbulent flow heat pump

A potential tower and ice chip technology, which is applied in the field of ice chip potential tower turbulent flow heat pump, can solve the problems of hydrostatic level pressure loss, poor antifreeze performance, and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

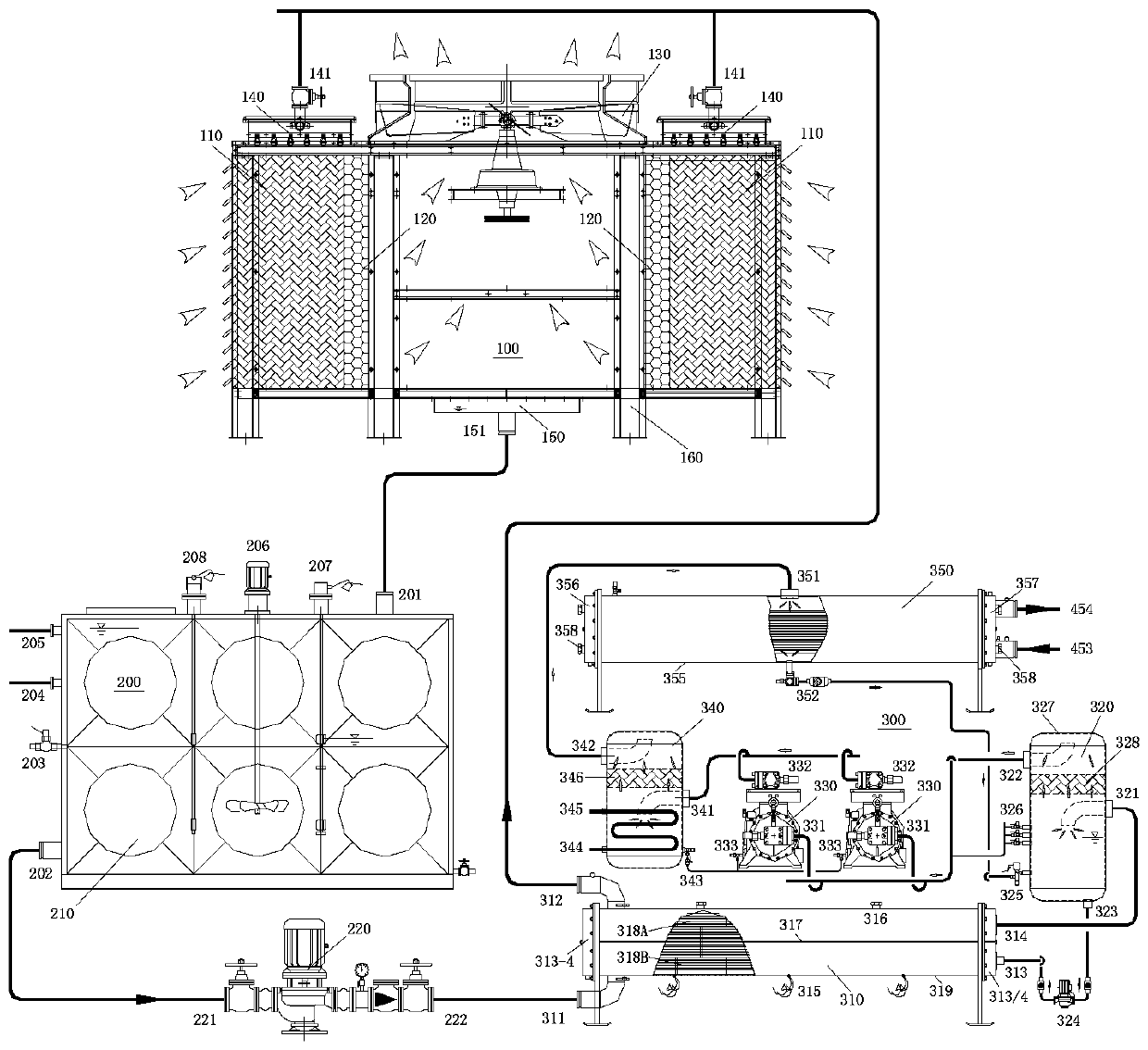

[0017] The following is combined with the accompanying drawings: figure 1 The schematic diagram of the connection structure of the "ice debris potential tower turbulent flow heat pump" of the present invention is further described.

[0018] With reference to accompanying drawing, the turbulent flow heat pump of the ice chips potential tower of the present embodiment.

[0019] Explanation: The hollow arrows in the figure indicate the air flow direction, and the solid arrows indicate the circulation flow direction of the circulating medium, working liquid and water body.

[0020] The ice chip potential tower turbulent flow heat pump comprises an ice chip phase change heat source tower (100), a cooling liquid regulating circulation station (200), and an ice chip phase change turbulent flow heat pump unit (300).

[0021] The ice chip phase change heat source tower (100) includes a symmetrical wetting filler (110), a symmetrical mist collector (120), a pneumatic device (130), a sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com